Superfine eucommia ulmoides powder and preparation method thereof

A technology of eucommia powder and low-temperature crushing, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, plant raw materials, etc., which can solve the problems affecting the use effect and the utilization rate of medicinal materials, and achieve less pollution, high purity, and easy processing The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

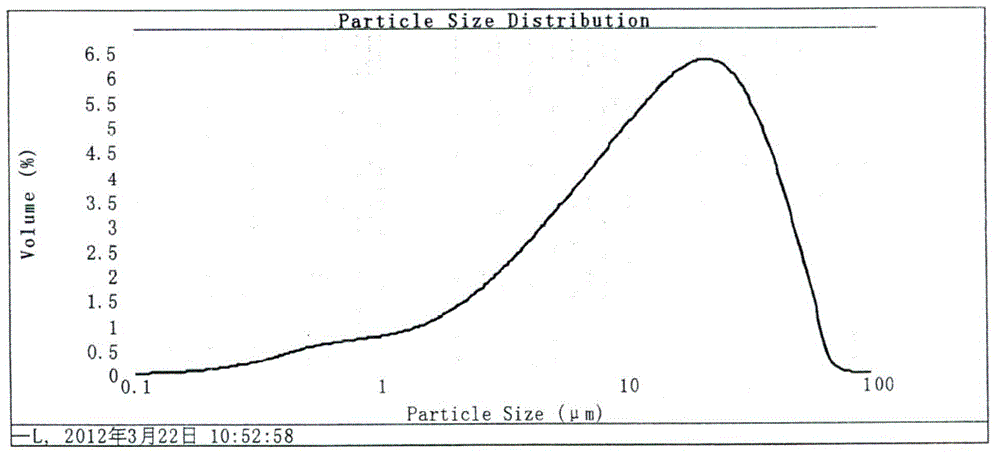

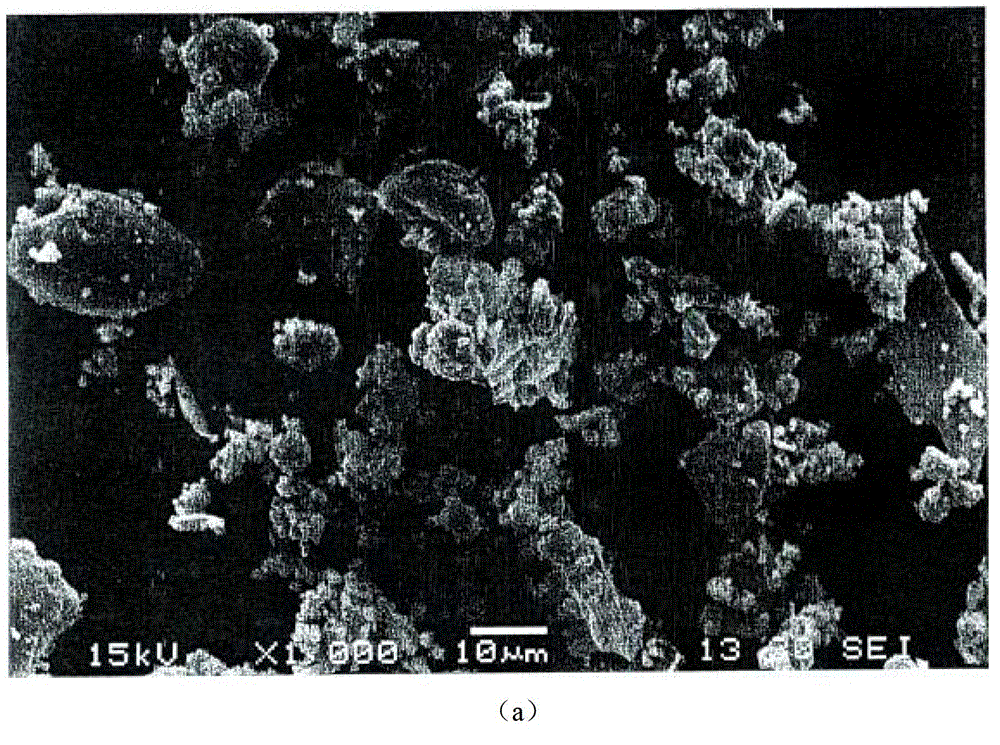

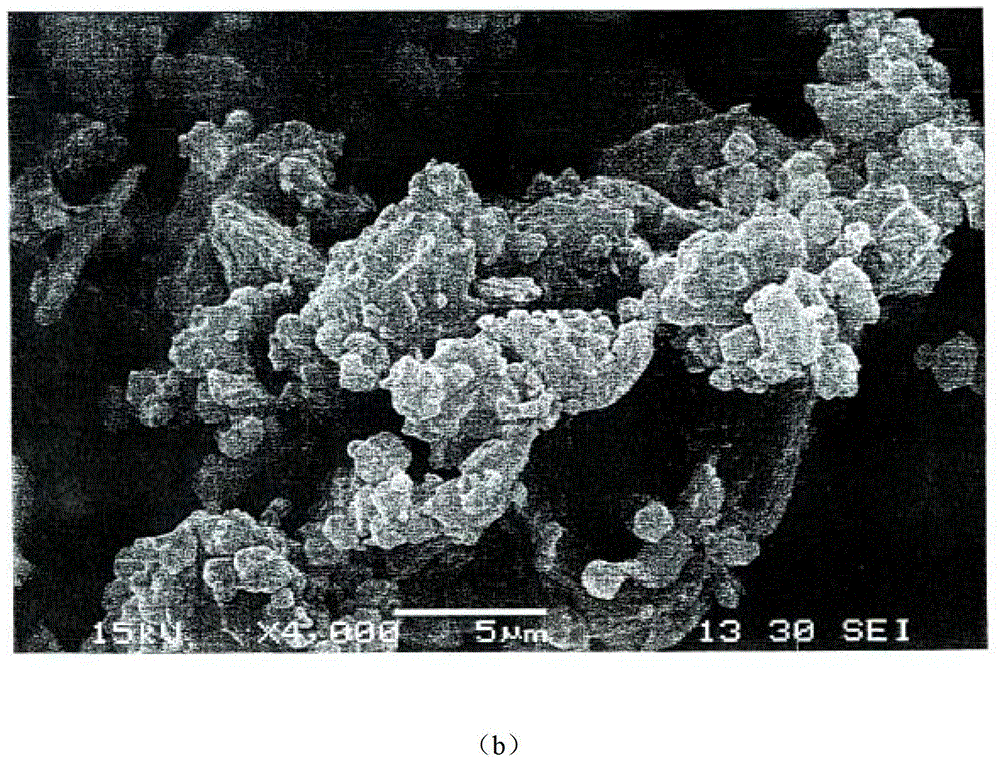

[0042] The bark flakes of Eucommia ulmoides collected in the Sichuan base were measured to have a moisture content of 45-50%. They were dried with YRD-1030 vacuum drying equipment produced by Shanghai Yucheng Drying Equipment Co., Ltd. The temperature is -20°C, the vacuum degree is adjusted to 45-55Pa, the vacuum drying temperature is controlled at 40-45°C, and the drying time is 15-18 hours, so that the water content of Eucommia after dehydration is controlled below 2%, and then sealed in the first Put it into the jet mill for pulverization, and the domestic flat jet mill is STG-10 series. The diameter of the studio used in jet milling is φ100-150mm, the number of nozzles is 4, the angle between the axis of the nozzle and the radius of the studio is 30°-50°, and the nozzle is installed in the middle of the studio. The production capacity is 10-20kg / h, and the median particle size of the product is about 10-15μm.

Embodiment 2

[0044] The water content of the initial Eucommia bark flakes is 45% to 50%, the pre-freezing temperature is -30°C, the drying temperature is 50°C, and the dehydration stage is extended for 2 hours in the later stage of drying, a total of 20 hours. The water content of Eucommia is below 1%. The median diameter of the particles obtained after pulverization is in the range of 10-12 μm, and the rest are the same as in Example 1.

[0045] From the above two examples, the lower the water content after freeze-drying, the more thorough the dehydration and the easier the crushing of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com