Formula of aureomycin hydrochloride premix granule and granulating process

A technique of chlortetracycline hydrochloride and premix, which is applied in the direction of non-active ingredient medical preparations, pharmaceutical formulations, pill delivery, etc. It can solve the lack of uniformity and roundness of particle shape, the impact on the physical and mental health of operators, and product impurities Problems such as component improvement, to achieve the effect of protecting the content of effective components, consistent color, and reducing the production of impurity components

Active Publication Date: 2012-10-10

PUCHENG CHIA TAI BIOCHEM

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the dry granulation process of aureomycin hydrochloride premix granules, a hydraulic pressure wheel is used to compress the material and the sieved returned powder, and then the product is obtained by crushing and sieving. Heat-sensitive chlortetracycline hydrochloride causes the loss of effective components, and also increases the impurity components of the product, decreases the stability of the product, and uneven color of the product. At the same time, the shape of the particles lacks uniformity and roundness through flaky crushing and granulation. , because the production of premixes has certain requirements on cleanliness, the whole production process must be carried out in a clean workshop, and dust will be generated during the batching, crushing, granulation and product collection processes, which will pollute the workshop and the surrounding environment, seriously affecting Its cleanliness also has a great impact on the physical and mental health of operators

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0020] Chlortetracycline Hydrochloride 50%;

[0021] Corn starch 45%;

[0022] Glucose 5%;

[0023] Pure water 30%.

Embodiment 2

[0025] Chlortetracycline Hydrochloride 80%;

[0026] Corn starch 5%;

[0027] Glucose 5%;

[0028] Pure water 10%.

Embodiment 3

[0030] Chlortetracycline hydrochloride 5%;

[0031] Corn starch 80%;

[0032] Glucose 10%;

[0033] Pure water 5%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

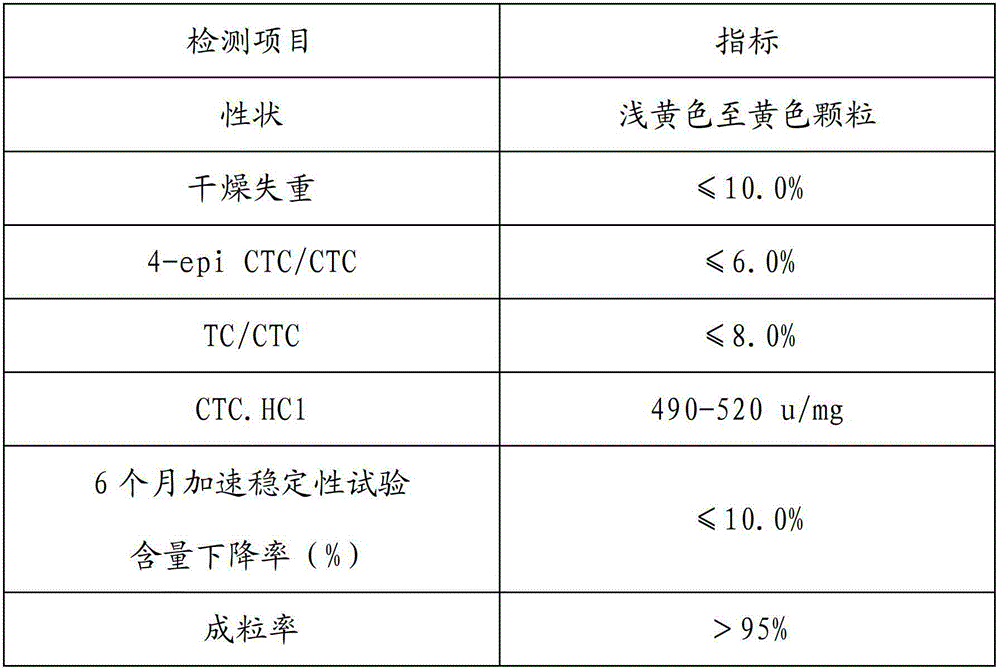

The invention discloses a formula of aureomycin hydrochloride premix granule, which is characterized in that the following components are included: 80 percent or less than 80 percent of aureomycin hydrochloride, 80 percent or less than 80 percent of soluble starch or starch degradation products, 20 percent or less than 20 percent of carbohydrates, and 30 percent or less than 30 percent of purified water. The invention further discloses a granulating process. After the adoption of the formula and the granulating process, the invention achieves that the aureomycin hydrochloride premix granule is uniform, has a mellow appearance, is unanimous in tincture and high in percentage of ripened grains, the stability of product quality is excellent, the normal working conditions during the aureomycin hydrochloride premix granulating process can be ensured, and the improvement to production efficiency and quality is facilitated.

Description

technical field [0001] The invention relates to the field of production of chlortetracycline hydrochloride, in particular to a formula and a granulation process of chlortetracycline hydrochloride premix granules. Background technique [0002] In the dry granulation process of aureomycin hydrochloride premix granules, a hydraulic pressure wheel is used to compress the material and the sieved returned powder, and then the product is obtained by crushing and sieving. Heat-sensitive chlortetracycline hydrochloride causes the loss of effective components, and also increases the impurity components of the product, decreases the stability of the product, and uneven color of the product. At the same time, the shape of the particles lacks uniformity and roundness through flaky crushing and granulation. , because the production of premixes has certain requirements on cleanliness, the whole production process must be carried out in a clean workshop, and dust will be generated during th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A61K9/16A61K9/20A61K31/65A61K47/36A61K47/26

Inventor 林贞

Owner PUCHENG CHIA TAI BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com