Method for degrading konjac gum and preparing kappa-carrageenan compound colloid

A technology of konjac gum and carrageenan, used in food preparation, application, food science, etc., can solve the problems of low colloidal transparency and long heating time, and achieve the effect of not easy to bubble and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

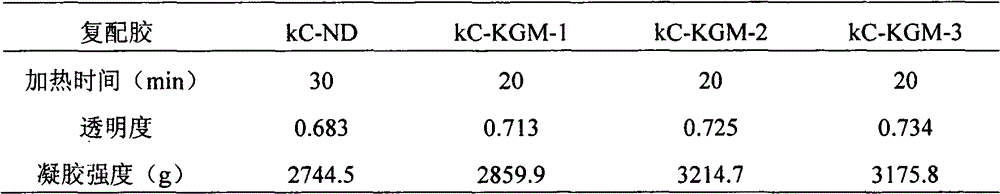

[0013] Use β-mannosidase to enzymatically hydrolyze konjac gum. At a temperature of 55°C, the mass fraction of konjac gum is 12% (prepared with deionized water), the amount of enzyme added is 3.5U / g, and the enzymatic hydrolysis time is 90min. The resulting degraded konjac gum The viscosity is 2010mpa·s.

[0014] The degraded konjac gum and κ-carrageenan were heated at 75° C. for 20 min with constant stirring, and then the gel was cooled at room temperature for 12 h. The ratio of konjac gum and κ-carrageenan was 4:6, and the total gum concentration was 1.5%. The gel strength of the compound colloid was determined to be 3214.7g at this time.

Embodiment 2

[0016] Use β-mannosidase to enzymatically hydrolyze konjac gum. At a temperature of 55°C, the mass fraction of konjac gum is 12% (prepared with deionized water), the amount of enzyme added is 3.5U / g, and the enzymatic hydrolysis time is 90min. The resulting degraded konjac gum The viscosity is 2010mpa·s.

[0017] The degraded konjac gum and κ-carrageenan were heated at 75° C. for 20 min with constant stirring, and then the gel was cooled at room temperature for 12 h. The ratio of konjac gum and κ-carrageenan was 4:6, and the total gum concentration was 1.0%. The gel strength of the compound colloid was determined to be 1120.8g at this time.

Embodiment 3

[0019] Use β-mannosidase to enzymatically hydrolyze konjac gum. At a temperature of 55°C, the mass fraction of konjac gum is 12% (prepared with deionized water), the amount of enzyme added is 5.5U / g, and the enzymolysis time is 120min, the resulting degraded konjac gum The viscosity is 1060mpa·s.

[0020] The degraded konjac gum and κ-carrageenan were heated at 75° C. for 20 min with constant stirring, and then the gel was cooled at room temperature for 12 h. The ratio of konjac gum and κ-carrageenan was 4:6, and the total gum concentration was 1.5%. The gel strength of the compound colloid was determined to be 3175.8g at this time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com