Threshing and sorting system for combined harvester

A combined harvester and cleaning technology, which is applied to harvesters, threshing equipment, cutters, etc., can solve the problems of shortening the effective working length of the threshing machine room, affecting the threshing quality, and food waste, so as to achieve easy manual maintenance, Improve work efficiency and increase adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in conjunction with the accompanying drawings.

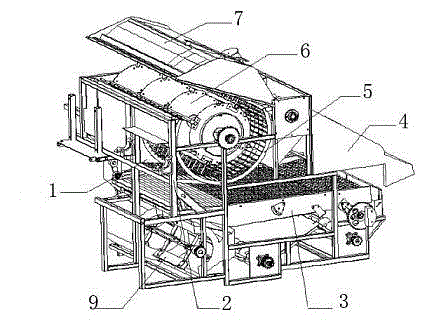

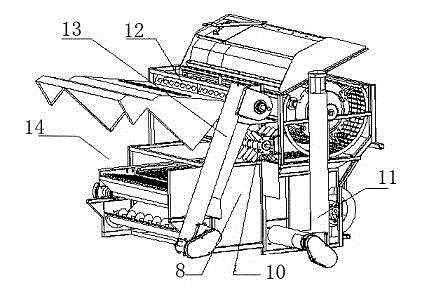

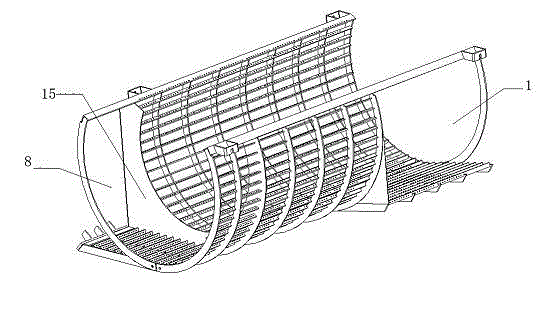

[0048] Such as figure 1 Shown in -2, the assembling connection relation of the present invention is: a kind of threshing and cleaning system of combine harvester, it comprises frame, crop feed inlet 1, thresher chamber 2, cleaning vibrating screen 3, thresher tail cover 4. Concave screen 5, threshing drum 6, drum cover 7, grass outlet 8, fan 9, stem chopping device 10, main auger 11, re-extraction device 12, redundant auger 13, thresher tail row miscellaneous mouth 14;

[0049] The crop feeding port 1 is located at the upper left front of the thresher chamber 2, and the length of the cross section of the crop feeding port 1 is greater than 540 mm; the grass discharge port 8 is located at the lower right rear of the thresher chamber 2, and the threshing drum 6 is installed at the upper front of the thresher chamber, The drum cover 7 is located above the threshing drum 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com