Modular power supply device with reverse prevention function and reverse-prevention control circuit

A technology of control circuit and power supply device, which is applied in the direction of output power conversion device, emergency protection circuit device, control/regulation system, etc., and can solve problems such as uneven flow of diodes, lower module efficiency, and increased module radiator. Achieve the effect of improving module load adjustment rate, improving module efficiency, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

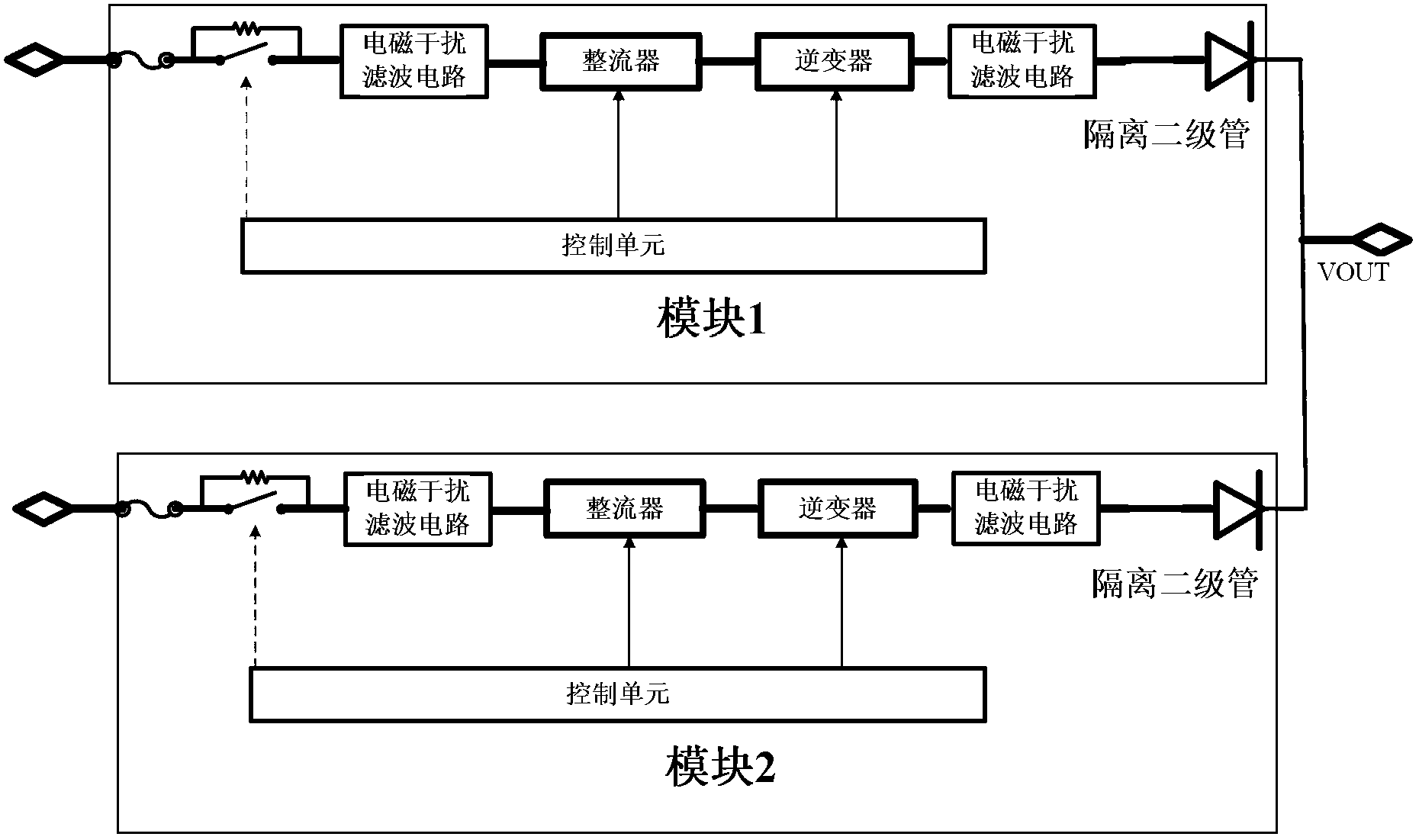

[0032] The present invention will be further described below in conjunction with drawings and embodiments. The present invention is described by taking a standardized railway signal module power supply as an example. For example, the standardized railway signal module power output specification is a voltage of 24V, a rated current of 75A, and a peak current of 82.5A. Combined with the above main parameters of the power supply of the railway signal module, it will be described in detail through specific embodiments.

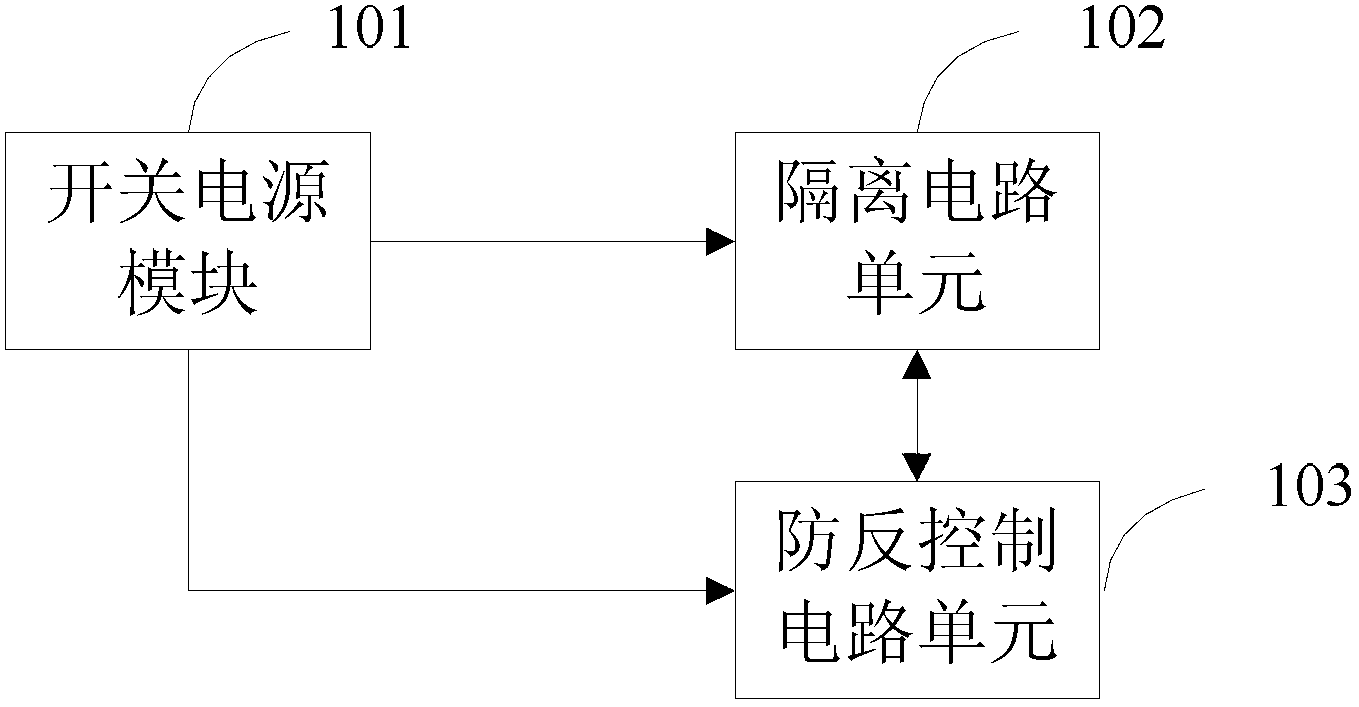

[0033] image 3 A functional block diagram of a modular power supply device with an anti-reverse function provided for a specific embodiment of the present invention. Such as image 3 As shown, the modular power supply device with anti-reverse function includes a switching power supply module 301, an isolation circuit unit 302 and an anti-reverse control circuit unit 303, and the switching power supply module 301 and the isolation circuit unit 302 and the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com