Image sensor and manufacturing method of transistor

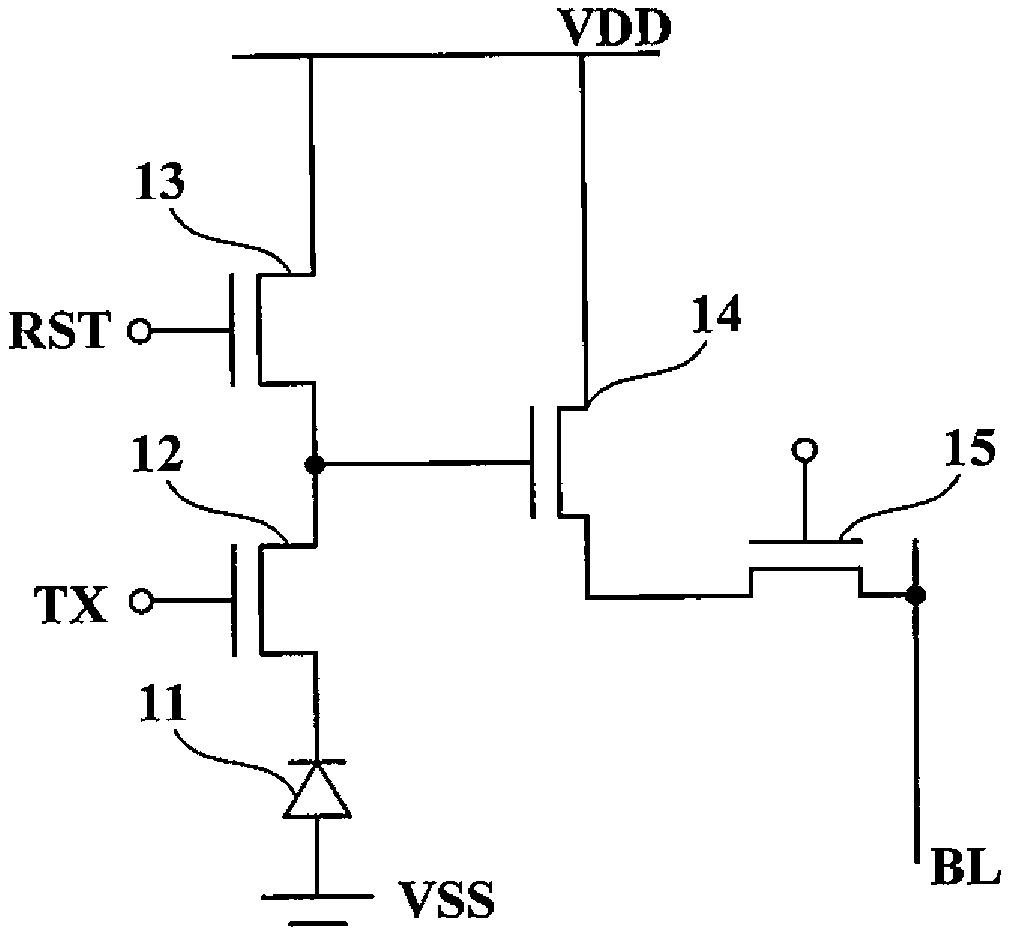

A technology of image sensor and manufacturing method, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor device, etc., and can solve the problems of image quality reduction, large flicker noise of voltage signal, obvious flicker noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

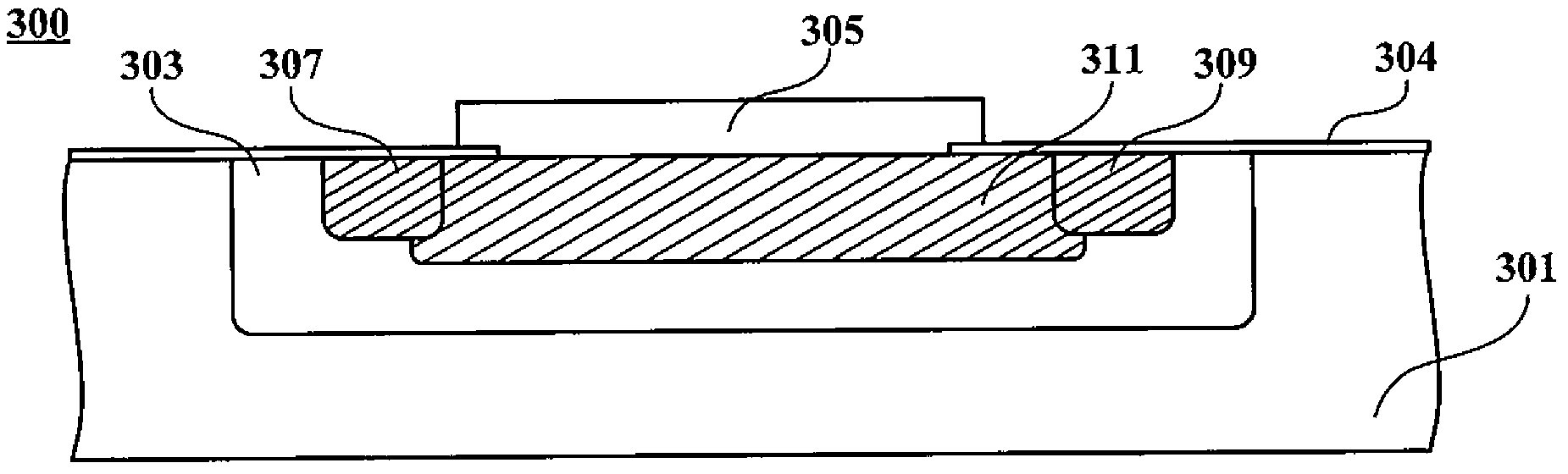

Method used

Image

Examples

Embodiment Construction

[0028] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

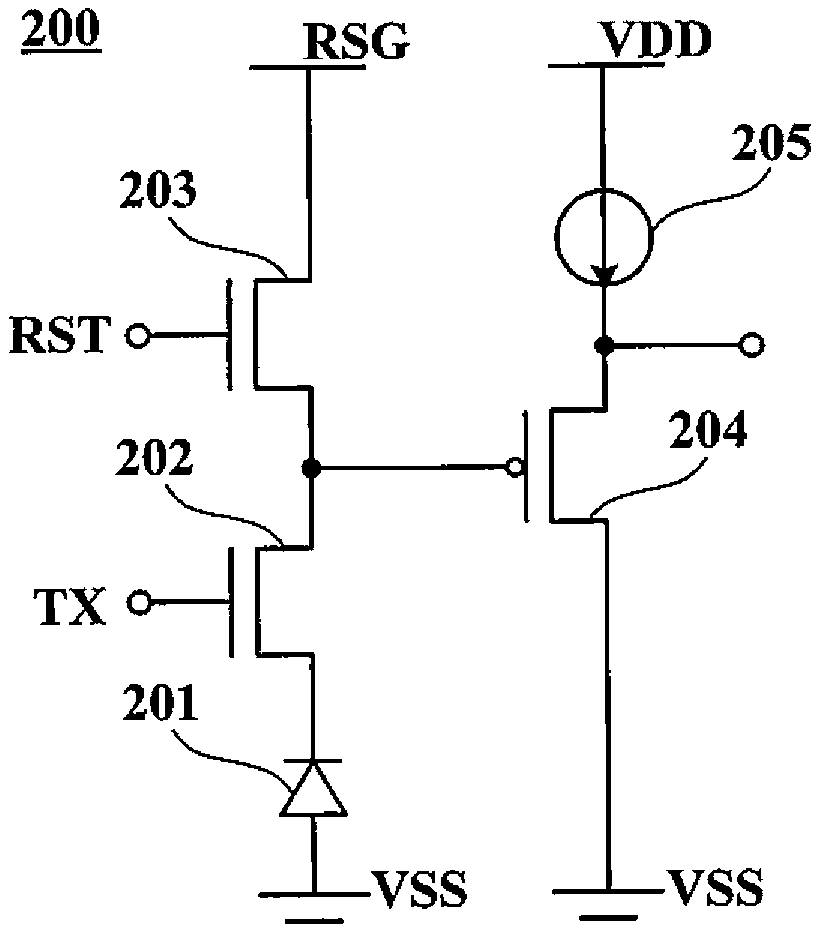

[0029] refer to figure 2 , shows an image sensor 200 according to an embodiment of the present invention, the image sensor 200 includes a pixel array, and each pixel unit in the pixel array includes: a photodiode 201 for sensing light intensity changes to generate corresponding image charges signal; a transfer transistor 202 for transferring the image charge signal; and a source follower transistor 204 for generating a voltage signal based on the transferred image charge signal, wherein the source follower transistor 204 is a junction field effect transistor.

[0030]It should be noted that, in some examples, multiple pixel units in the pixel array may have one source follower transistor 204, for example, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com