Hollow lead-free plastic flat package

A cavity-free, flat package technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems that MEMS chips and optoelectronic semiconductor chips cannot be plastic-packed, and achieve mass production, shorten the length of bonding wires, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

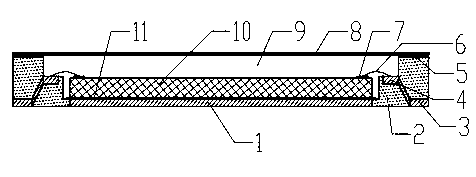

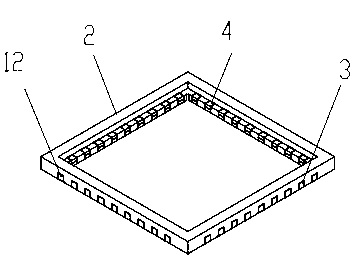

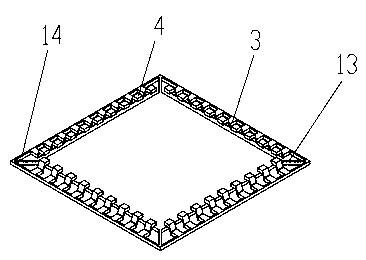

[0023] According to attached figure 1 It can be seen that the present invention specifically relates to a cavity leadless plastic flat package, including a carrier 1, on which a chip 10 is fixed, and pins are evenly distributed around the carrier 1, between the pins and between the pins and the carrier. Filling through the plastic package 2, the plastic package 2 bonds the pins and the carrier 1 into one, the plastic package 2 is an insulating material, and can be filled by injection molding.

[0024] According to attached figure 2 It can be seen that the pins and the chip 10 are connected through the bonding wire 6, and the top of the chip 10 is provided with a cover plate 8, and the periphery of the cover plate 8 is supported by the plastic package body 2, and the connection between the cover plate 8, the carrier 1 and the plastic package body 2 A cavity 9 is formed between them, and a MEMS chip with an exposed movable structure is placed in the cavity 9, which is the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com