Vibrating disk type drier with burbling function

A vibrating plate and dryer technology, applied in the direction of dryers, drying chambers/containers, drying, etc., can solve the problems that the seamless cooperation between the scraper and the heating plate surface cannot be guaranteed, the purity of the material is reduced, and it is not very smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

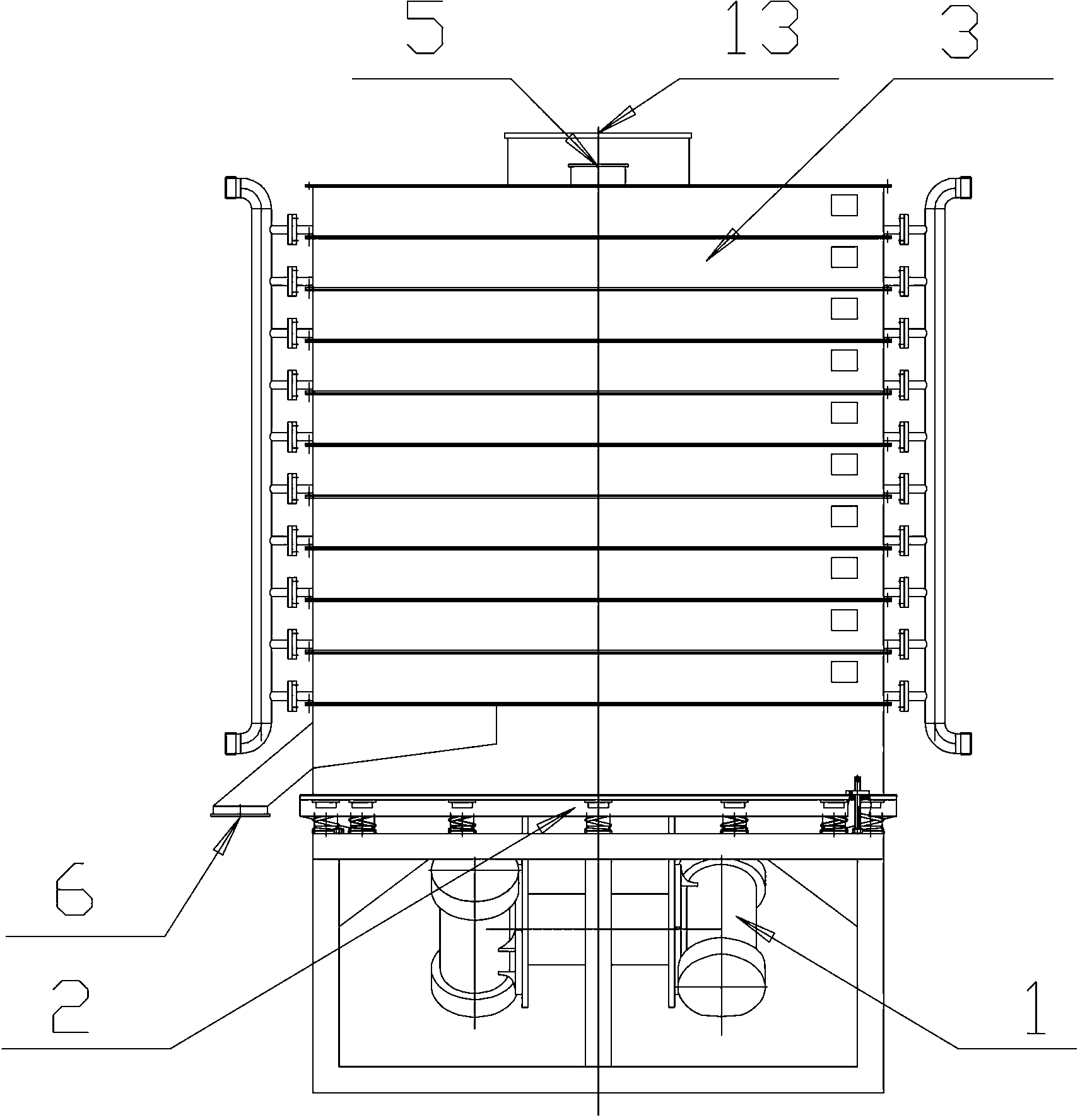

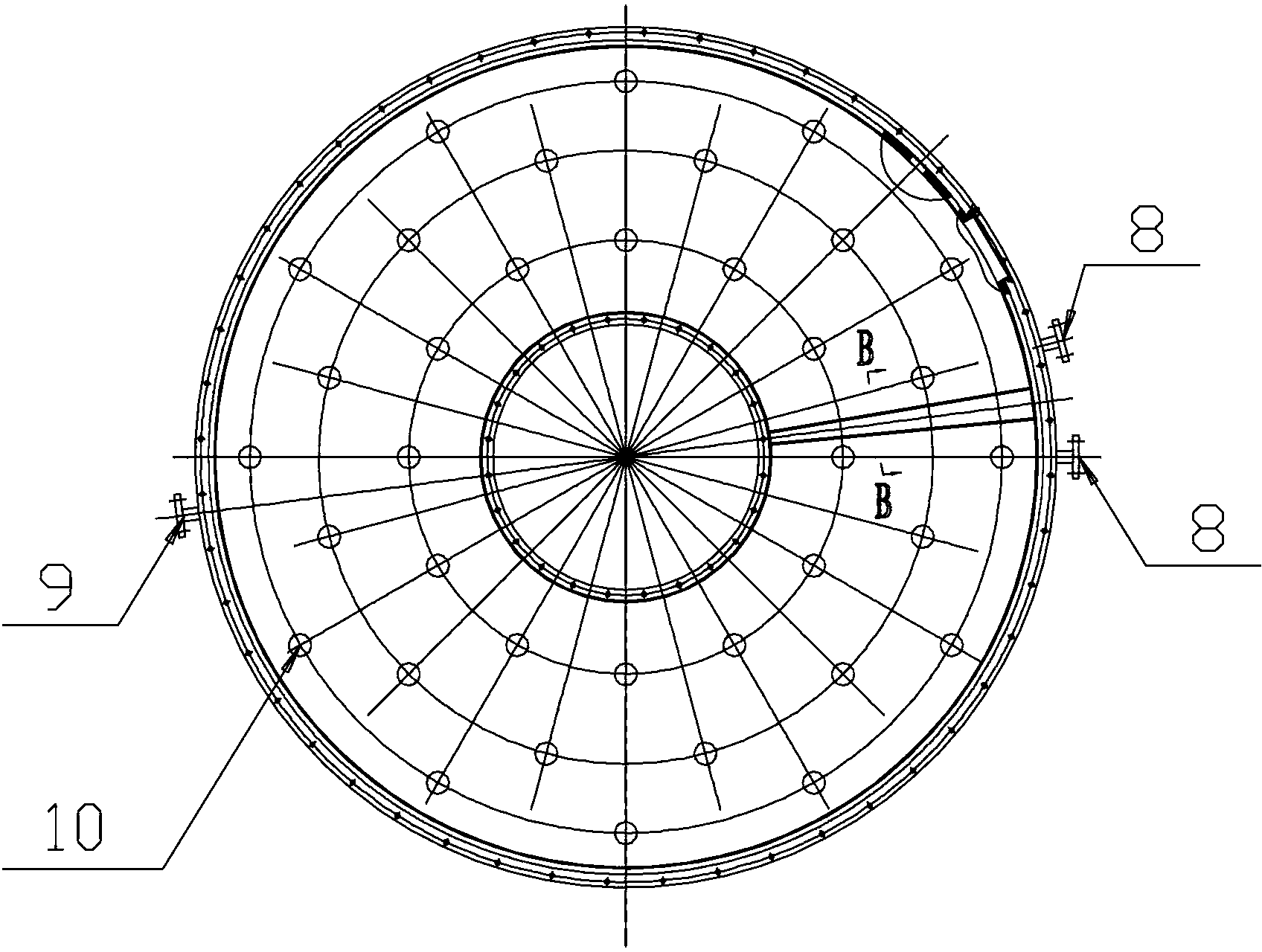

[0015] Such as Figure 1 to Figure 3 As shown, a vibrating disc dryer with turbulence function includes a vibrating motor 1, a vibrating chassis 2 and a vibrating spring arranged therebetween. It is characterized in that: above the vibrating chassis 2, several The vibrating plate 3, the upper and lower surfaces of each vibrating plate 3 are respectively provided with an inlet and an outlet, and the outlet of each vibrating plate 3 corresponds to the entrance position of the vibrating plate 3 below; the upper surface of the uppermost vibrating plate 3 is for feeding Port 5, the outlet of the lower surface of the bottom vibrating plate 3 is the discharge port 6; an interlayer 7 is provided at the bottom of each vibrating plate 3, and the interlayer 7 and the oil inlet 8 arranged on the outer circumference of the vibrating plate 3 It communicates with the oil outlet 9, the oil inlet 8 of each layer of vibrating plate 3 communicates with the oil inlet pipe, and the oil outlet 9 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com