Device and method for separating CO2 by circulating fluidized bed chemical looping-combustion of coal and combustible solid waste

A circulating fluidized bed and chemical chain combustion technology is applied in fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state. , easy gasification, the effect of solving the problem of reaction matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

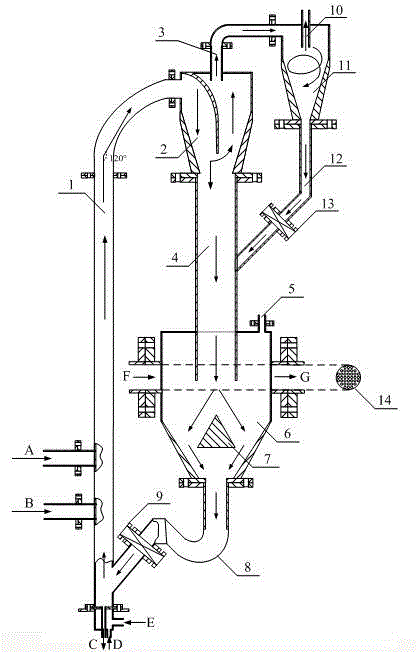

[0023] Refer to the following figure 1 To describe in detail the coal and combustible solid waste circulating fluidized bed chemical looping combustion separation CO of the present invention 2 method, the oxygen carrier is iron ore (the main component is Fe 2 o 3 ) as an example.

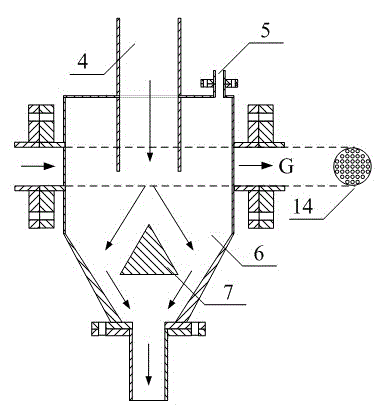

[0024]1) The air distribution plate arranged at the bottom of circulating fluidized bed solid waste reactor (hereinafter referred to as fuel reactor) 1 is the gasification agent inlet, and there are two inlets on the lower left side, the upper one is combustible solid waste inlet A, and the lower one is coal Particle entrance B. The right side is the primary return inlet. water vapor and CO 2 The mixture is used as the gasification agent and fluidization medium, respectively from the reactor gasification agent (water vapor) inlet D and the reactor gasification agent (CO 2 ) into the inlet E, carrying the combustible solid waste particles entering from the combustible solid waste inlet A, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com