Refillable vertical movable gas cylinder

A gas cylinder and vertical technology, which is applied in the field of low-temperature thermal insulation gas cylinders, can solve problems such as unsatisfactory gas purity, and achieve the effects of simple structure, enhanced strength, and enhanced support performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

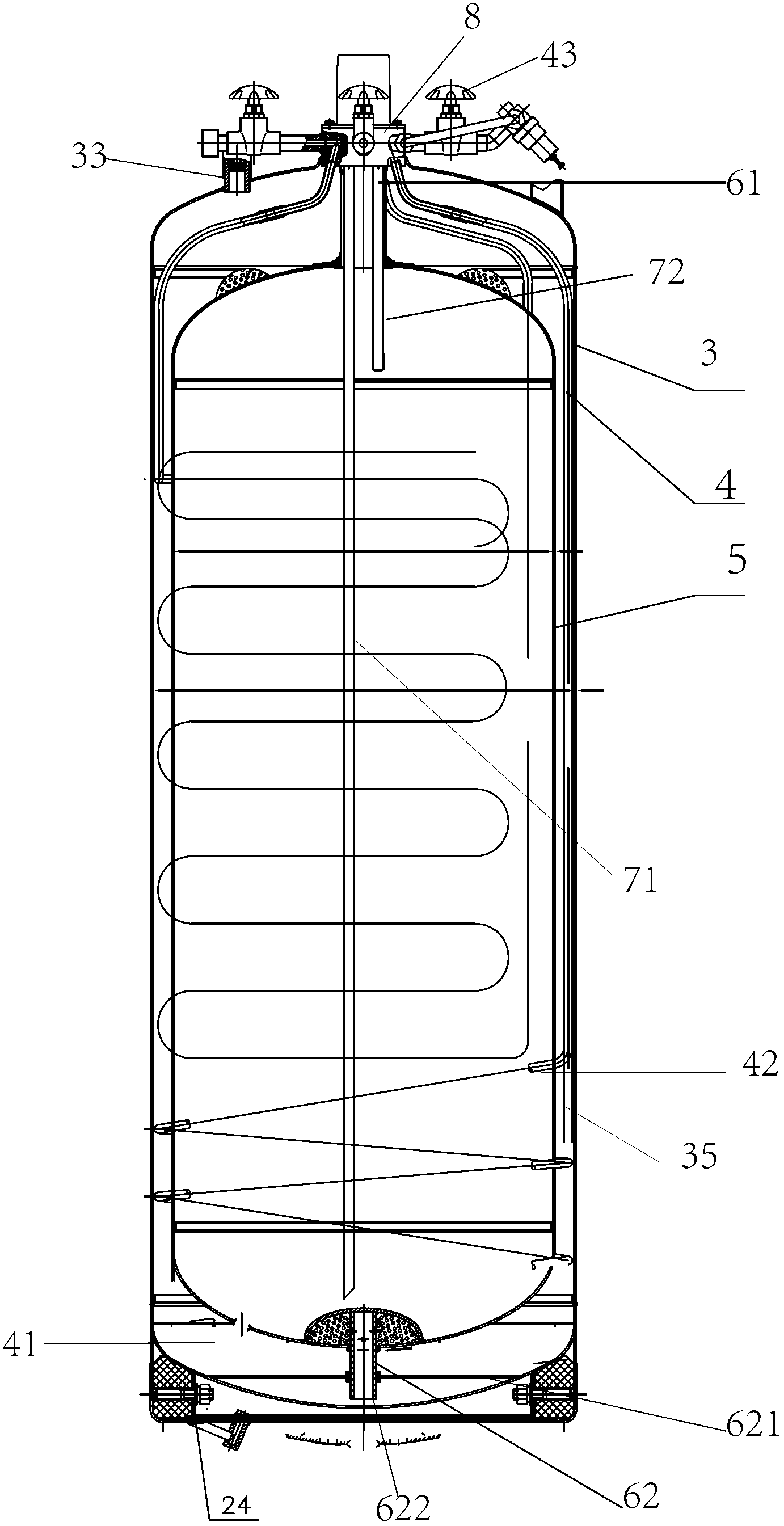

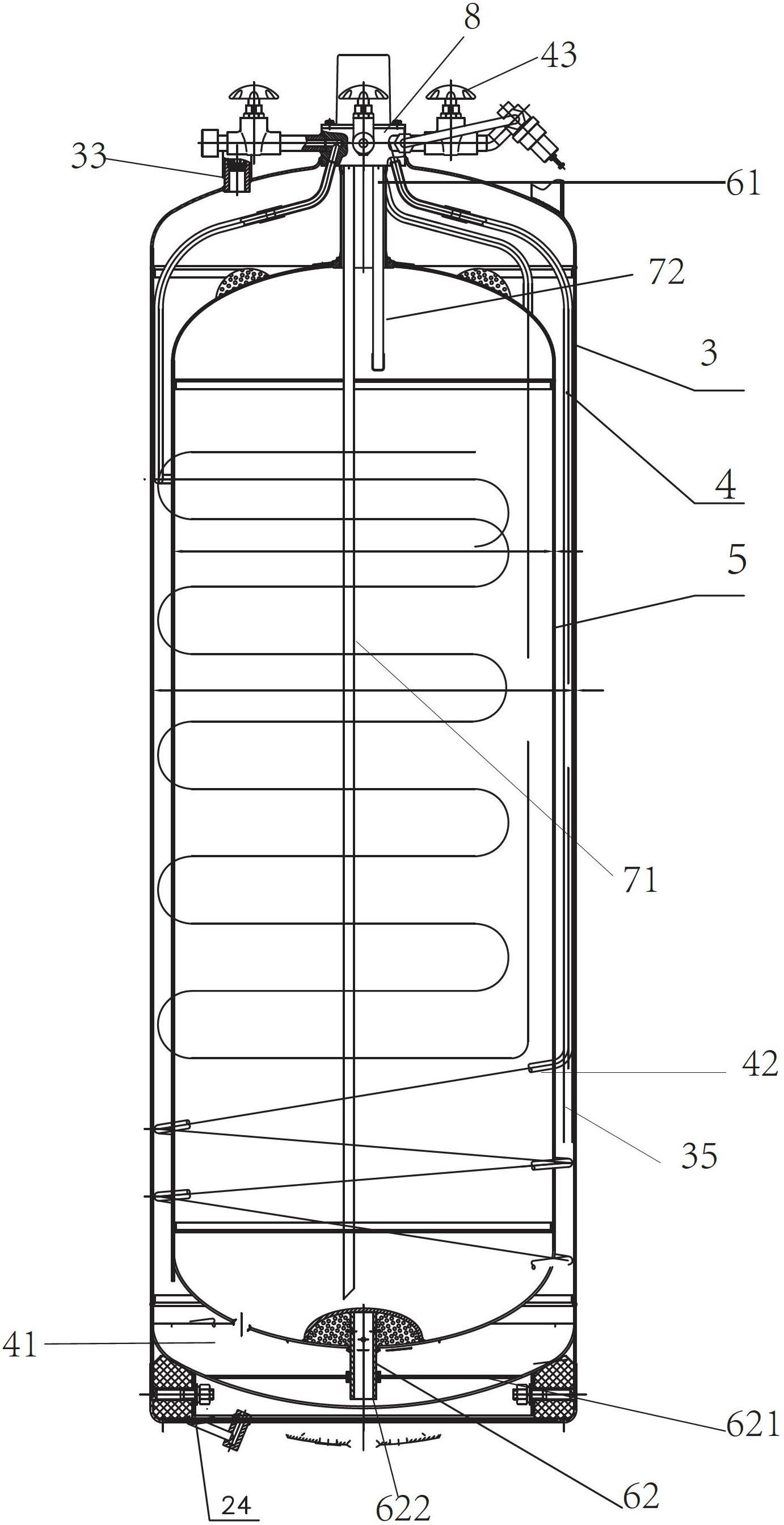

[0013] The refillable vertical mobile gas cylinder of the present invention is composed of an austenitic stainless steel inner tank 5, an outer shell 3, a support structure 6 connected to the inner tank, at least one inflation pipe 4 and an exhaust pipe 7, the inner tank The space 35 between the 5 and the shell 3 is a vacuum, the end 41 of the gas-filled tube 4 communicates with the inner tank 5 and the tube body 42 is penetrated in the space 35 .

[0014] The inflation tube 4 includes at least one pipeline, which is arranged between the inner tank 5 and the shell 3 in the form of a spiral curve, and the ends of each pipeline are connected to the bottom of the inner tank 5 .

[0015] The exhaust pipe 7 includes a long pipe 71 and a short pipe 72, the long pipe 71 has a valve on the top end, and the end of the long pipe 71 extends into the position below the inner bag 5, the short pipe 72 also has a valve on the upper end, and The end of the short tube 72 is close to the mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com