Left-handed and right-handed rotation nut locking device for large-diameter shaft end

A large-diameter, anti-loosening technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of not being able to tighten the ends of large-diameter shafts well, and the nuts are easy to loosen, etc., to achieve simple structure, avoid mutual friction, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

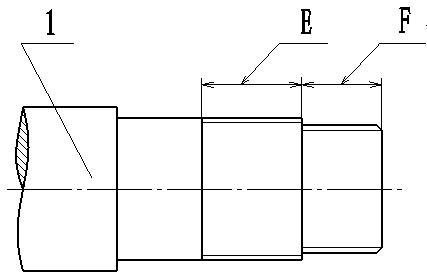

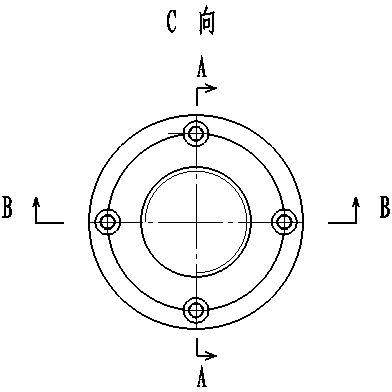

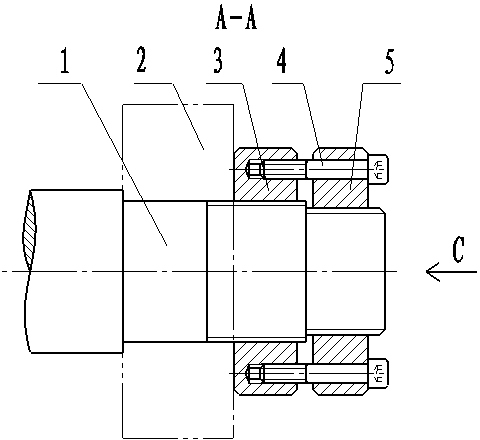

[0022] The E section and F section at the end of the large-diameter shaft 1 are provided with right-handed threads, the E section is right-handed, and the F section is left-handed. The fixed nut 3 is right-handed and left-handed. The lock nut 5 It is left-handed and right-handed, and the anti-loosening device is composed of a fixed nut 3, a tension screw 4, a push screw 6 and a lock nut 5. The front end of the tension screw 4 has threads, and the rear end has no threads. The rear end of the opening screw 6 is threaded, and the front end is unthreaded. Two blind holes and two internally threaded holes are processed on the circumferential direction of the fixing nut 3. The blind holes and internally threaded holes are arranged crosswise. 2 light through holes and 2 internal thread through holes are processed in the direction, the light through holes and the internal thread through holes are arranged crosswise, the threaded front end of the tension screw 4 passes through the light...

Embodiment 2

[0025] The E section and F section at the end of the large-diameter shaft 1 are provided with left-handed threads, the E section is left-handed, and the F section is right-handed. The fixed nut 3 is left-handed and right-handed. The lock nut 5 The anti-loosening device is composed of a fixed nut 3, a tension screw 4, a push screw 6 and a lock nut 5. The front end of the tension screw 4 has threads, and the rear end has no threads. The rear end of the opening screw 6 is threaded, and the front end is unthreaded. Two blind holes and two internally threaded holes are processed on the circumferential direction of the fixing nut 3. The blind holes and internally threaded holes are arranged crosswise. 2 light through holes and 2 internal thread through holes are processed in the direction, the light through holes and the internal thread through holes are arranged crosswise, the threaded front end of the tension screw 4 passes through the light through hole on the lock nut 5 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com