Multi-ring connected Stirling reversible heat engine

A technology of heat engine and heat, which is applied in the direction of hot gas variable displacement engine devices, mechanical equipment, machines/engines, etc., can solve the problems of large pressure fluctuations and large changes in the volume of the working chamber, and achieve strong heat dissipation, small overall volume, Solve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

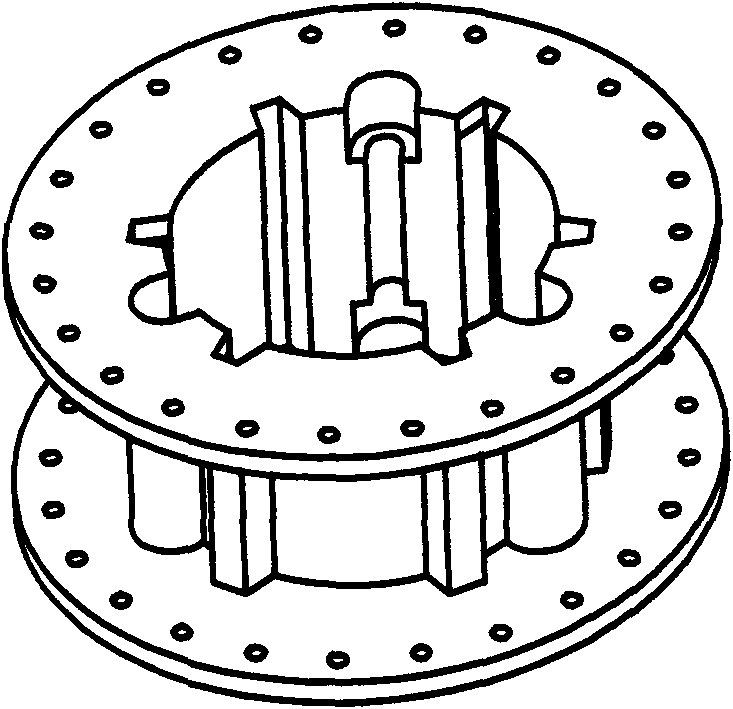

[0037] This embodiment is a Stirling generator with six working chambers and double ring connection for solar thermal power generation. The temperature of the heat storage medium in the existing solar heat storage technology can reach above 400°C. Take 400°C (673.15K) as the heat source temperature to design a generator with an output power of 300KW.

[0038]The main structural parameters are: cylinder diameter 200mm, stroke 120mm, distribution circle diameter 600mm, flow volume 10L, orientation block 100mm; heat engine diameter 1000mm, heat engine length 950mm excluding regenerator, control system and generator.

[0039] The set working parameters are: maximum working pressure 9MPa, heat engine efficiency 0.25, heat source temperature 673.15K, cold source temperature 333.15K, speed 900 rpm.

[0040] The thermodynamic calculation result of a working chamber is: the output electric power Power is 52.47KW, the heat absorption power P h 209.9KW, cooling power P C It is 157.4KW...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com