Multipurpose blade type active engine

A vane-type, multi-purpose technology, applied in the direction of rotary piston engines, engine components, machines/engines, etc., can solve the problems of not too high temperature, increased oil burning, high energy consumption, etc., to achieve reasonable energy management and increase The effect of high thrust and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

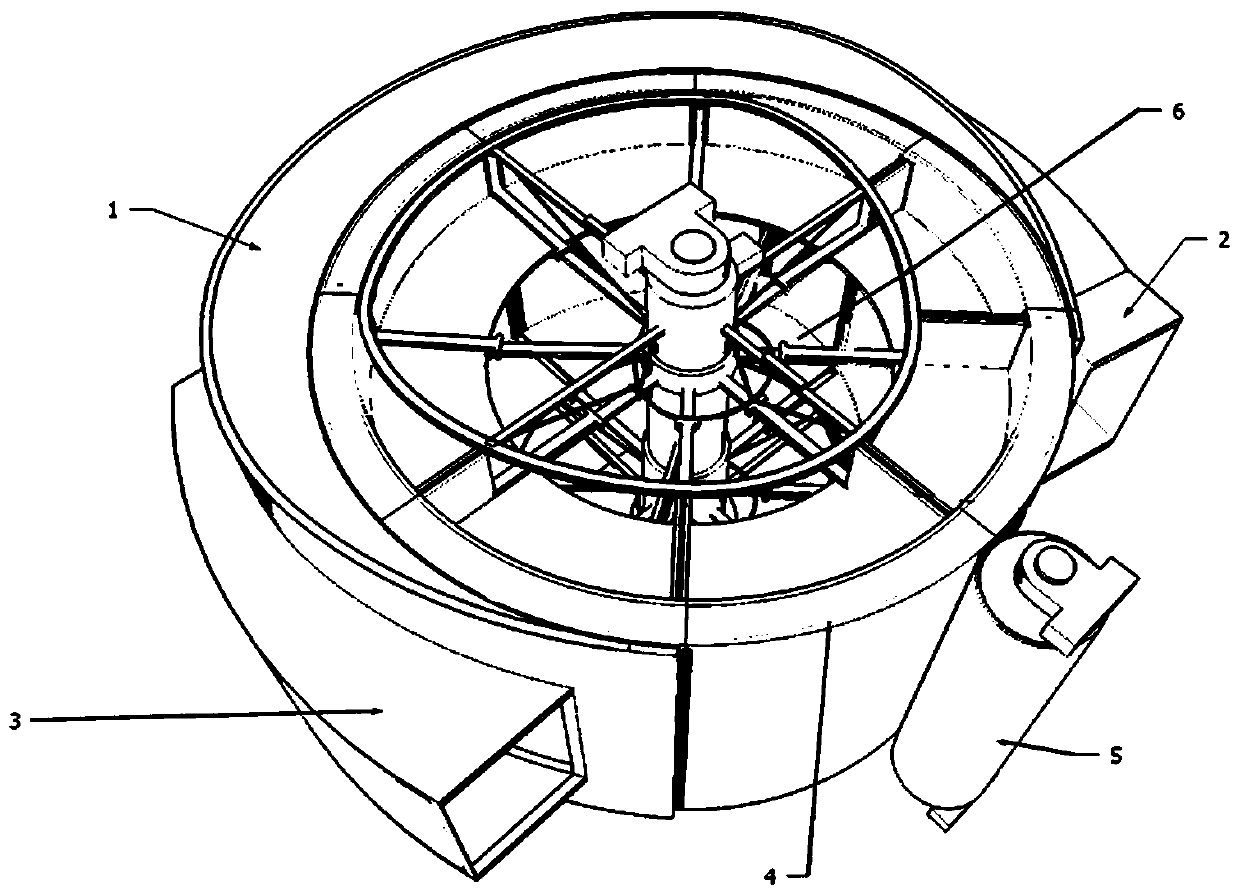

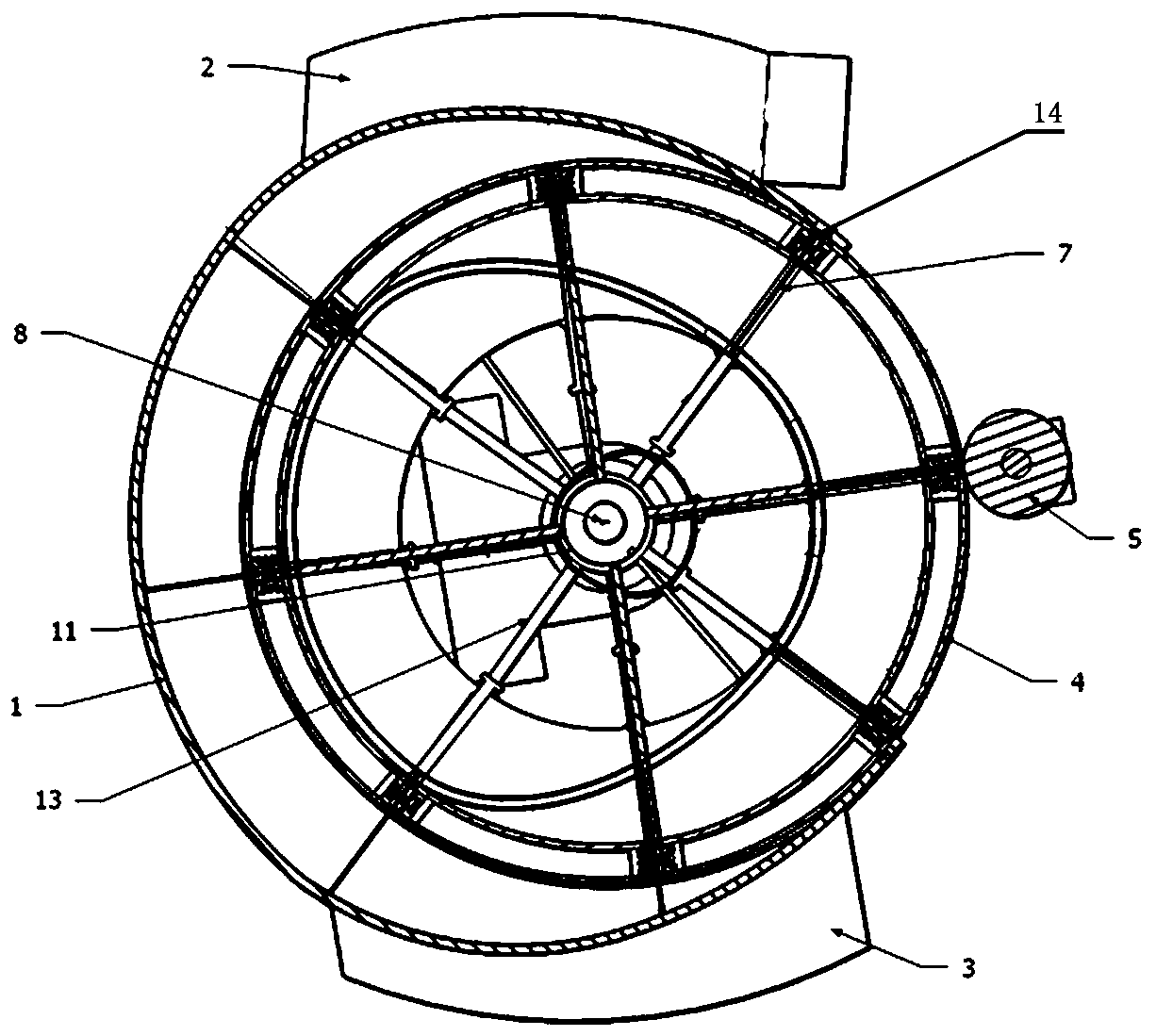

[0038] Such as figure 1 , 2 The multi-purpose vane-type motor shown includes a thermally rotating cavity and a rotor. The thermally rotating cavity is a crescent-shaped cavity, and the two ends of the cavity are provided with air inlets and exhaust ports. The rotor is installed on the thermally rotating Inside the cavity, the rotor is coaxial with the inner arc surface of the thermally rotating cavity, and a coaxial sealing wheel is arranged between the rotor and the thermally rotating cavity, and the upper and lower ends of the sealing wheel are respectively provided with an upper sealing plate and a lower sealing plate to form a seal Cavity; the rotor includes a shaft and a number of blades, the blades are evenly distributed on the shaft through the bracket circumferentially, and each blade passes through the sealing wheel, the upper sealing disc and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com