Comprehensive mechanization stone drift heading machine set

A technology of comprehensive mechanization and rock tunneling, applied in cutting machinery, slitting machinery, driving devices, etc., can solve the problems of low support height, many construction personnel, and high labor intensity of employees, so as to reduce the number of movements and ensure construction. Quality, effect of saving auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Carry out the specific embodiment of the present invention in detail below in conjunction with accompanying drawing:

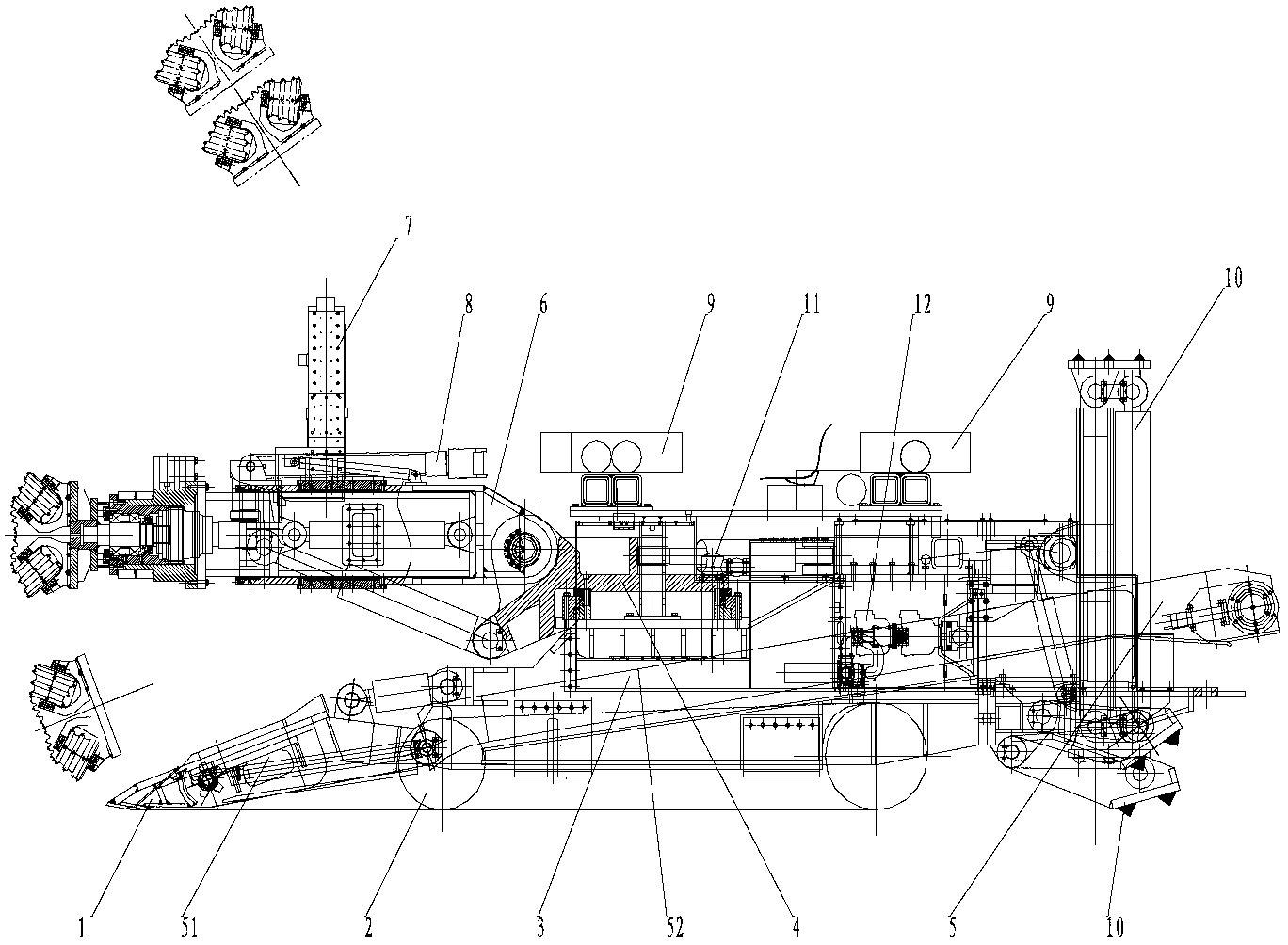

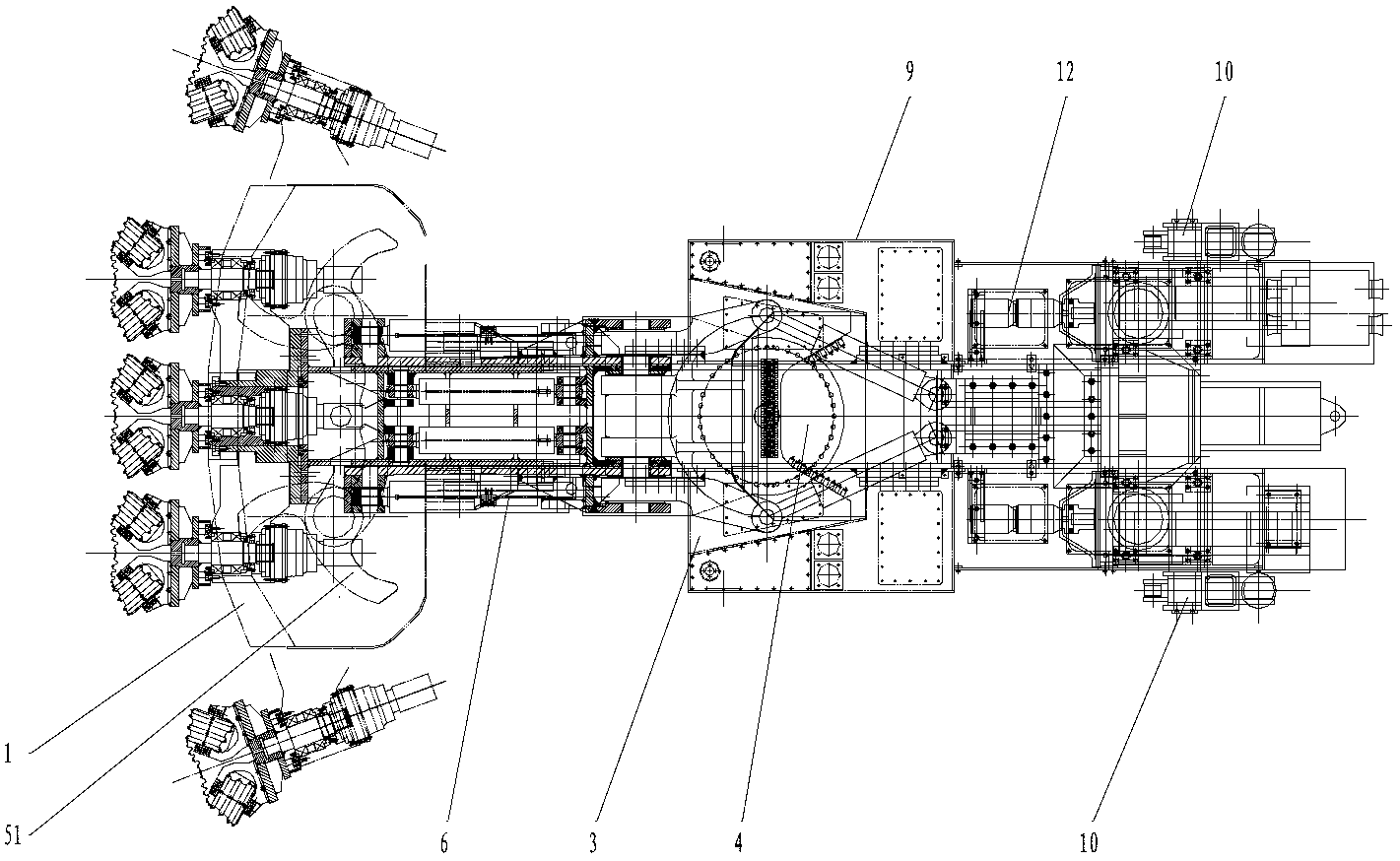

[0061] Such as figure 1 with figure 2 Shown, a kind of integrated mechanized rock roadway driving unit of the present invention, it is the model that three cutting devices are adorned in this unit front.

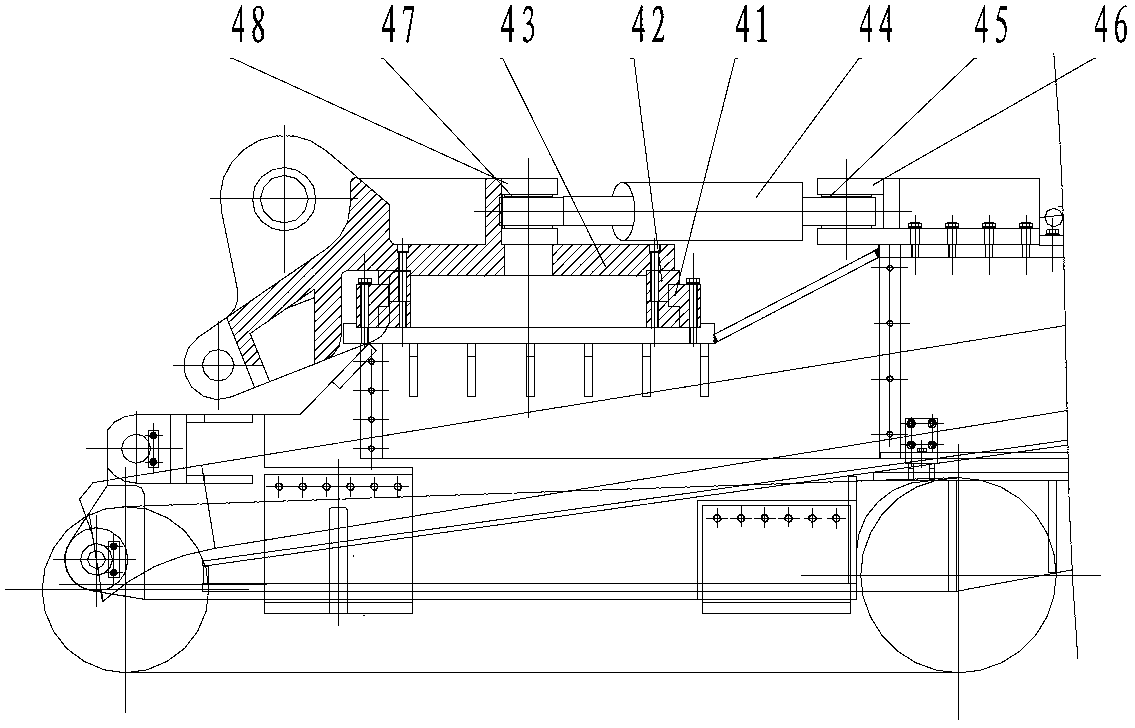

[0062] The comprehensive mechanized rock roadway excavation unit includes a shovel part 1, a crawler walking part 2, a frame 3, a rotating part 4, a belt transport part 5, a telescopic cutting part 6, a hydraulic drilling rig device 7, an advance support device 8, two Side support device 9, roof and floor support device 10, hydraulic control system 11 and electrical control system 12; the shovel part 1 is located below the front end of the entire unit, the crawler walking part 2 is installed directly below the unit, and the frame 3 is installed On the crawler walking part 2, it is used to support other parts of the whole unit; the rotating part 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com