Self-pushed type radial horizontal well steering device

A steering device and horizontal well technology, applied in directional drilling, drilling equipment, drilling automatic control system, etc., can solve problems such as increased operating costs, the length of the horizontal section cannot reach the predetermined depth, and the effect of increasing production is not obvious, so as to avoid Milling and reaming of casing segments, reducing operating costs and increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

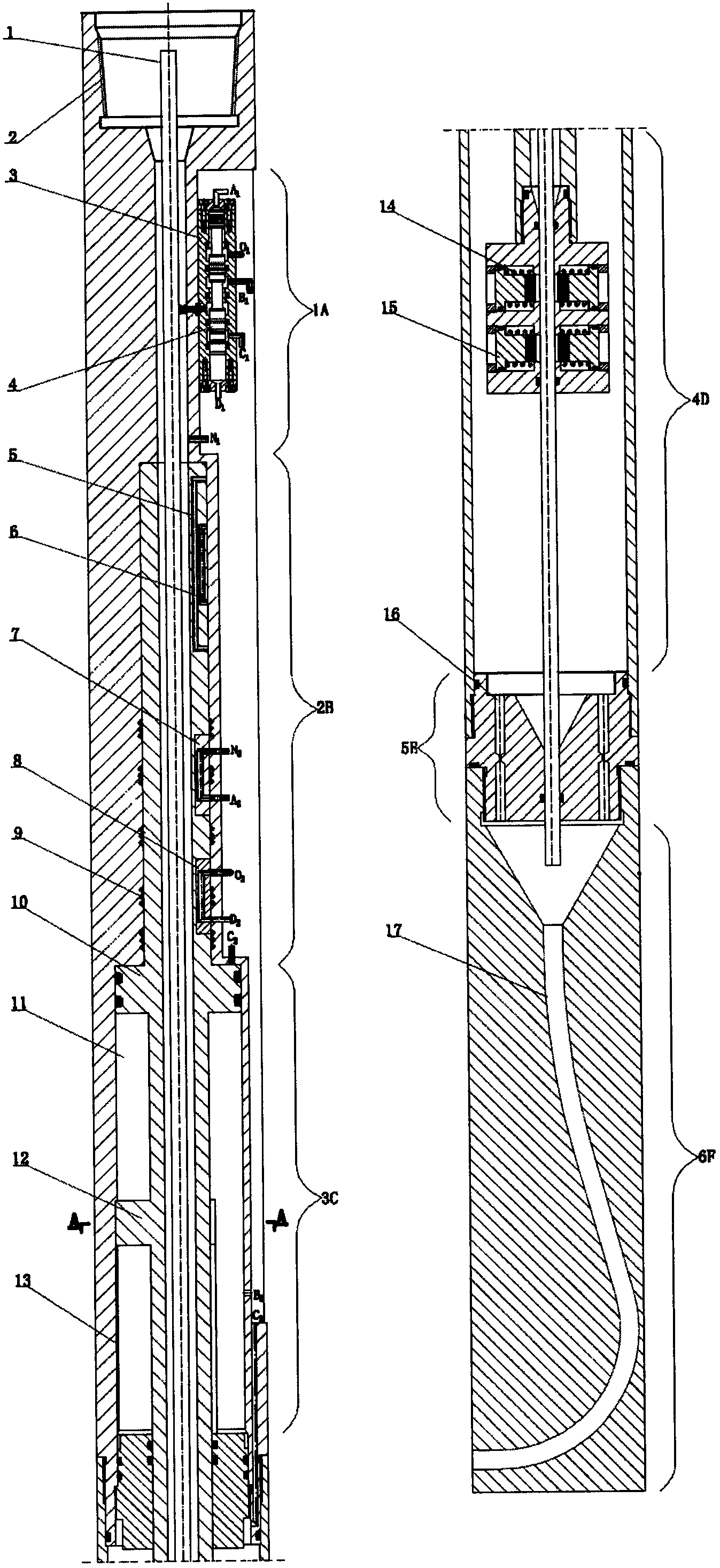

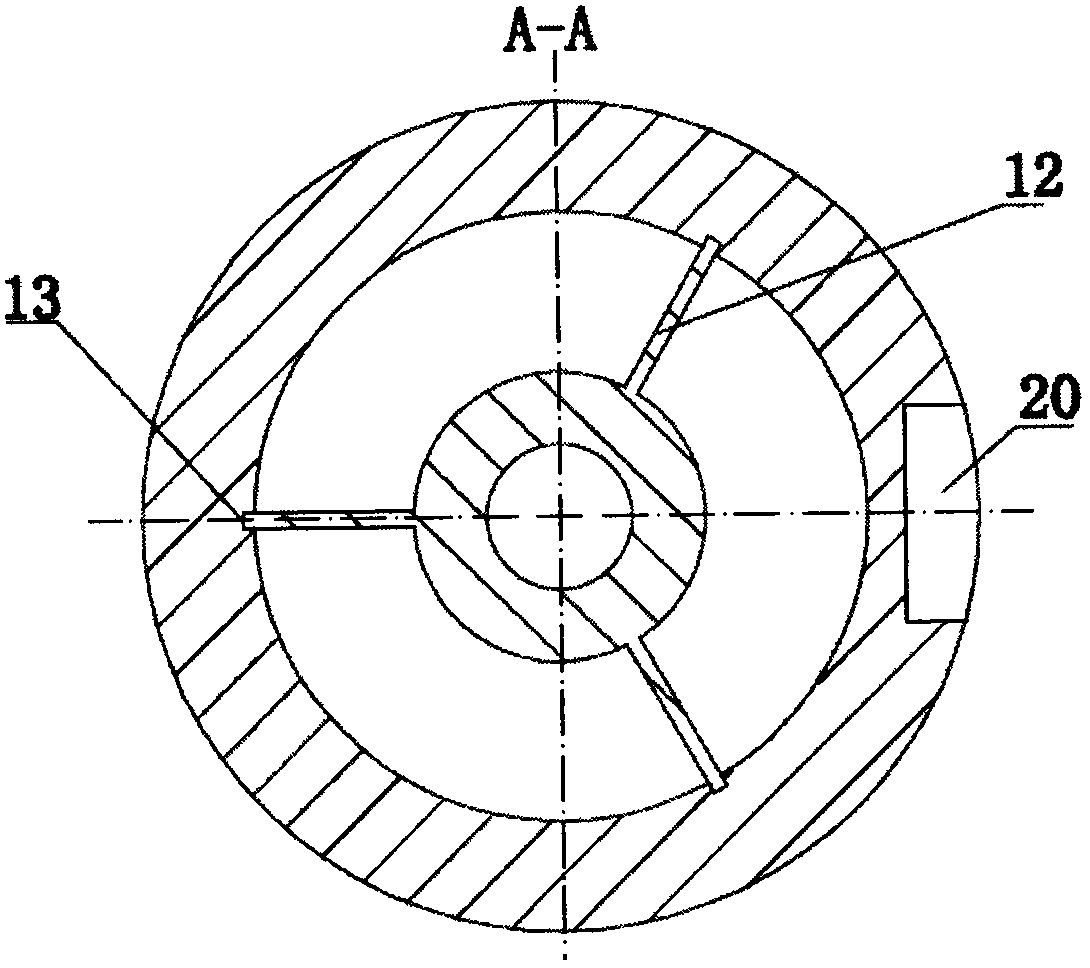

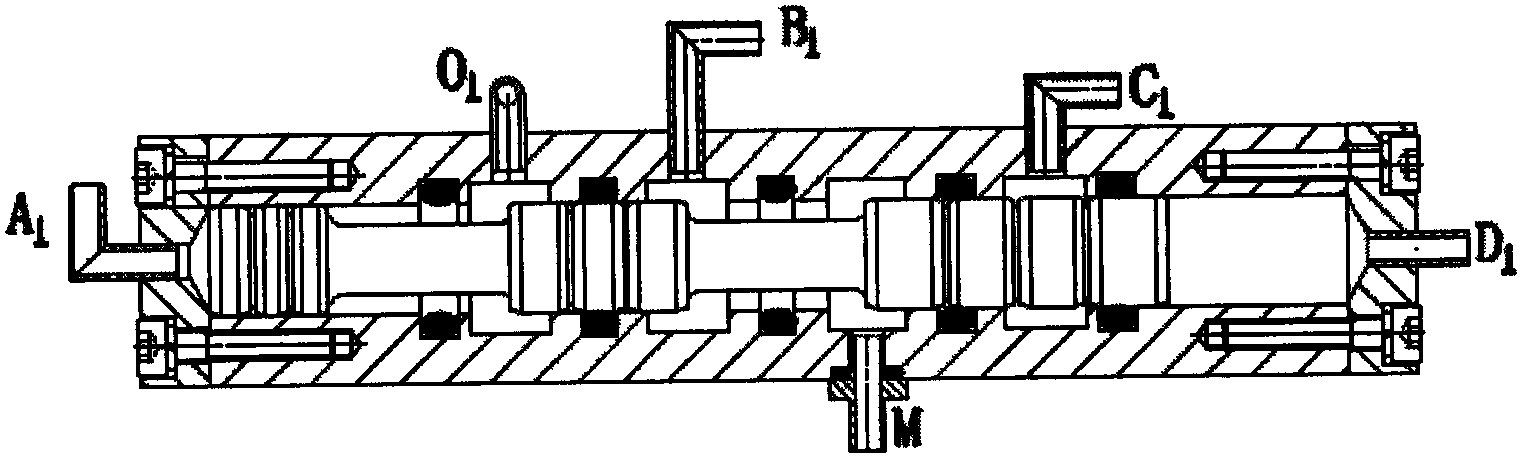

[0011] In the drawings, the steering device is connected to the oil pipe through the joint 2. There is a rectangular deep groove 20 on the device body to accommodate the reversing valve and the connection hole A 1 and hole A 2 , exit B 1 and hole B 2 , export C 1 , Hole C 2 and hole C 3 , Kong D 1 and hole D 2 , import N 1 and hole N 2 high pressure hose. In the piston cylinder assembly 3C, the labyrinth seal 9 ensures that the flow channel 6 and the flow channel 7 are connected to the hole N respectively. 2 and hole D 2 , Hole A 2 and hole O 2 without interfering with each other. The three wing plates located at the lower end of the piston rod and the corresponding three limit grooves on the inner wall of the cylinder ensure that the piston does not rotate during the reciprocating motion, so that the flow channel 5 and the flow channel 6 at the upper end of the piston rod are in line with the hole N 2 , Hole A 2 , hole O 2 , Kong D 2 During the reciprocating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com