Fully prestressed and compositely integrally reinforced concrete structure

A reinforced concrete, prestressed technology, applied in building construction, building maintenance, construction and other directions, can solve the problems of complex construction, no fire protection, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

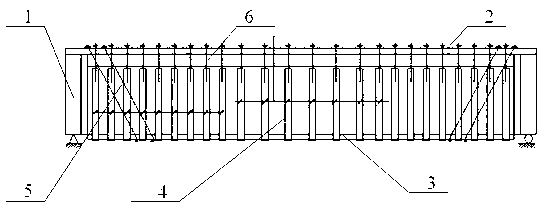

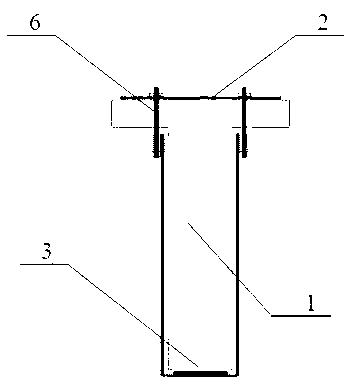

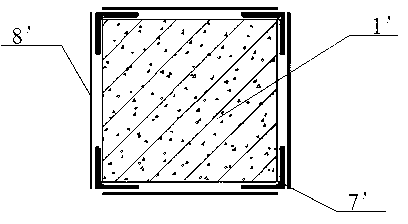

[0066] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0067] The purpose of the present invention is to provide a high-efficiency fully prestressed composite integrated reinforced reinforced concrete structure technology and method, which can improve the bending capacity of the original concrete structure and improve its deformation performance, and can also be used for components that have been damaged by load. It plays a very good role in repair and reinforcement, and can effectively solve the problems of "strain lag and interface damage" that cannot be completely solved by traditional reinforcement technology, and the reinforcement range can be determined without limitation according to engineering needs, so the practical application range is very wide. Can meet the actual needs of the project.

[0068] In the traditional prestressed reinforcement method, the prestress loss caused by the shrinkage of the tensile prestre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com