Method for producing frame of film-coated product of three-dimensional decorative board

A three-dimensional, decorative board technology, applied in the field of installation, frame of three-dimensional decorative board film-coated products, decorative board frame, frame production field, can solve problems such as high glue viscosity, environmental hazards, easy misalignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

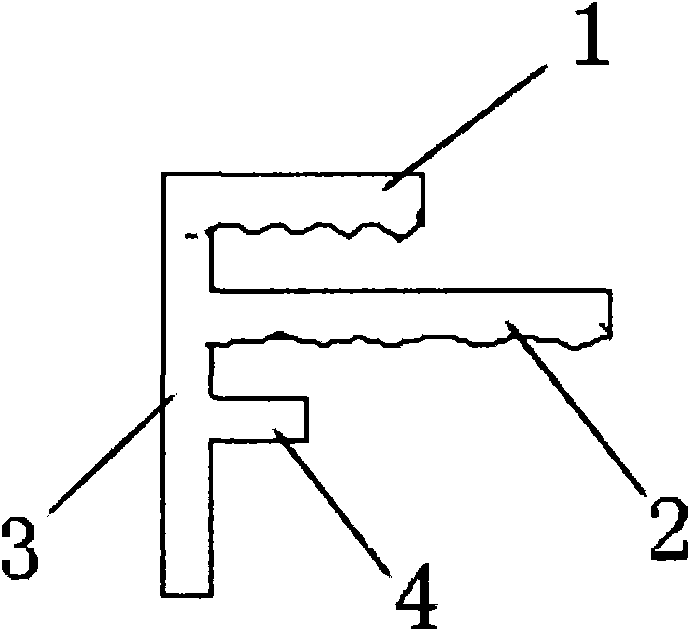

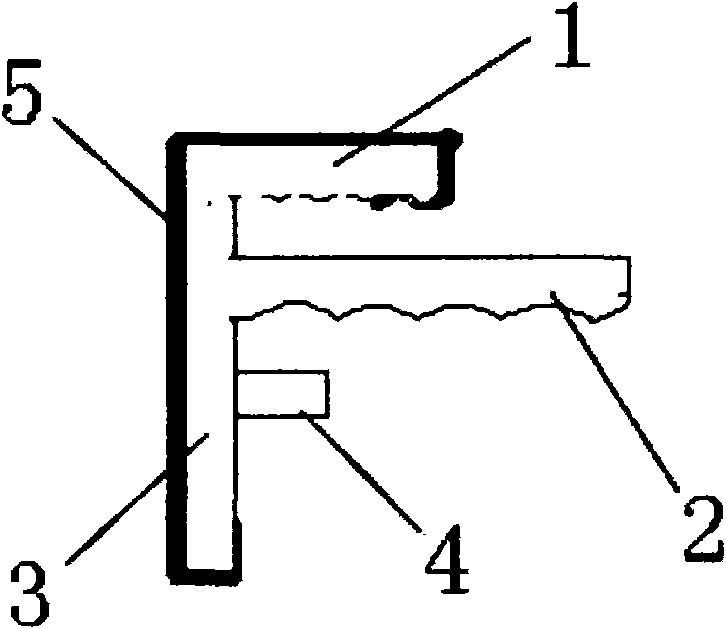

[0018] see figure 2 , the frame of the three-dimensional decorative board (three-pass board) film-coated product of the present invention includes a plane 1, a support end face 2, a vertical edge 3, a reinforcing strip 4 and a film coating 5, and the distance between the plane 1 and the support end face 2 is 1- 5 mm; the geometric dimensions of each part are determined according to the geometric dimensions of the three-dimensional decorative board (three-dimensional decorative board) film-coated product; the size can be as follows: the width of plane 1 is 3-10 mm, the thickness is 0.3-1.0 mm, and the standing edge The height of 3 is 10-15 mm, and the thickness is 0.5-1 mm. The width of support end face 2 is greater than the width of the plane, and the thickness is 0.5-1 mm. The width of reinforcing bar 4 is 3-5 mm, and the thickness is 0.5-1 mm.

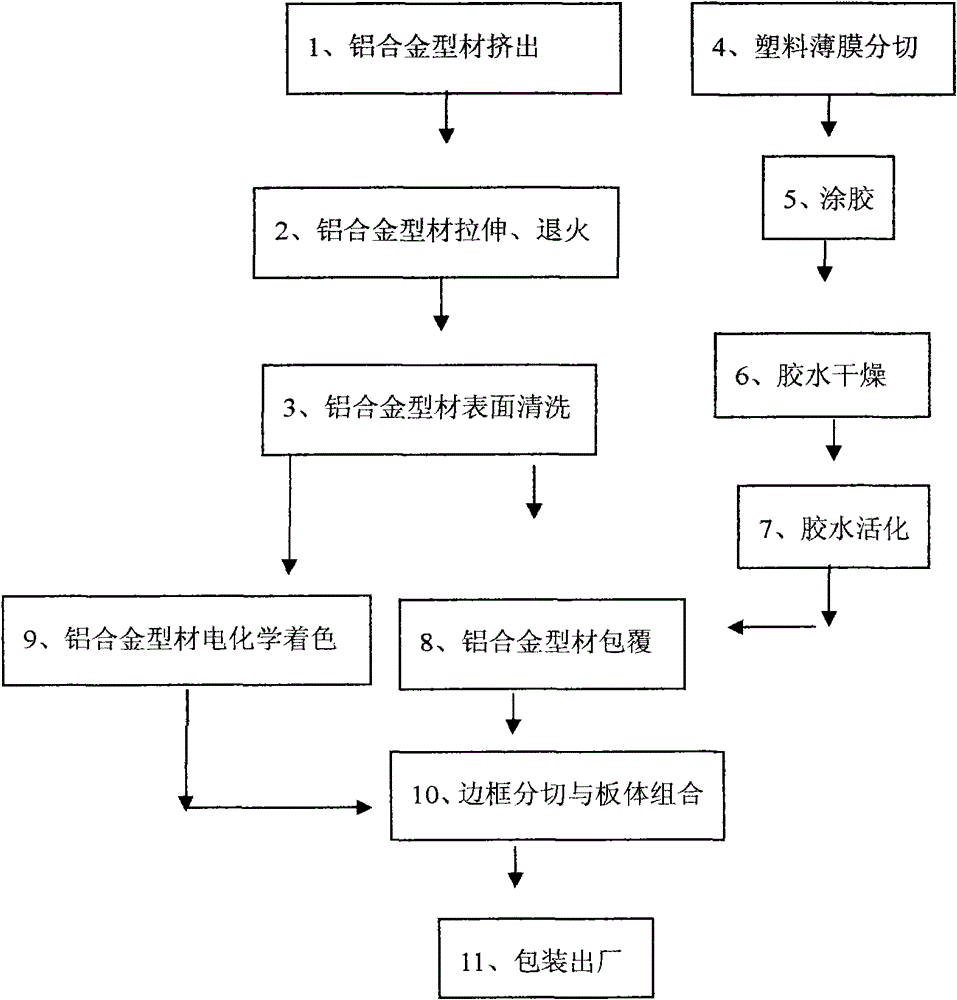

[0019] The production method of the frame of the film-coated product of the three-dimensional three-dimensional decorative board (...

Embodiment 2

[0028] The frame of a three-dimensional decorative board (three-dimensional decorative board) film-coated product is different from the first embodiment in that its surface is subjected to electrochemical coloring treatment, and after cleaning and oxidation chemical coloring, different metallic lusters such as gold, silver, and copper can be obtained. The surface effect, in use, can make the color of the border more prominent and more personalized.

Embodiment 3

[0030] A frame of a three-dimensional decorative board (three-dimensional decorative board) film-coated product is different from Embodiment 1 in that its surface treatment adopts sandblasting, wire drawing, and frosting processes to obtain a frame profile with surface texture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com