Drying judgment method for rotary washing machine

A drum washing machine, drying and heating technology, applied to other washing machines, washing machine control devices, washing devices, etc., can solve problems such as heating temperature differences, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

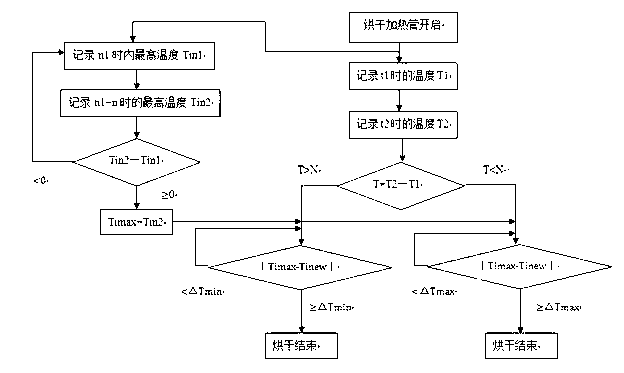

[0020] like figure 1 In the flow chart shown, first set t1 to 3 minutes, t2 to 15 minutes, N to 30, ΔTmax to 5, ΔTmin to 8, and n to 10 minutes.

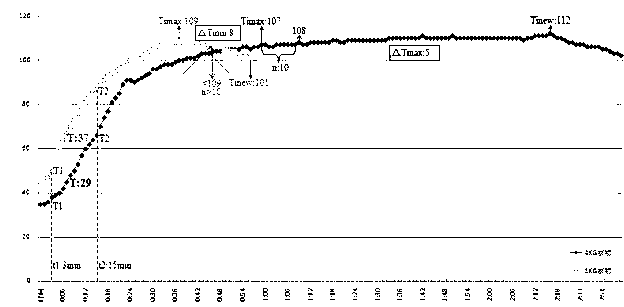

[0021] like figure 2 As shown, put 1kg of clothes into the inner drum of the washing machine. After the pre-cleaning process, start drying, turn on the drying heating pipe, and run until t1: 3 minutes. At this time, the temperature of the air inlet of the condenser is T1: 47 ℃;

[0022] When the heating tube runs to t2: 15 minutes, the air inlet temperature of the condenser T2: 84°C;

[0023] Calculate T=T2-T1=84°C-47°C=37°C, since 37>N=30, the washing machine system recognizes that there is a small amount of clothes in the inner drum of the washing machine;

[0024] At the same time, the temperature was 109°C 38 minutes after the drying heating tube was turned on, and the temperature in the next 10 minutes was less than 109°C, and the highest temperature value Timax of the air inlet of the condenser was calculated to be 109°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com