Method for smelting metal ores

A smelting method and metal ore technology, applied in the field of metal ore smelting, can solve the problems of high energy consumption and low metal smelting efficiency, and achieve the effects of reducing pollution, preventing explosion or poisoning, and accelerating reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

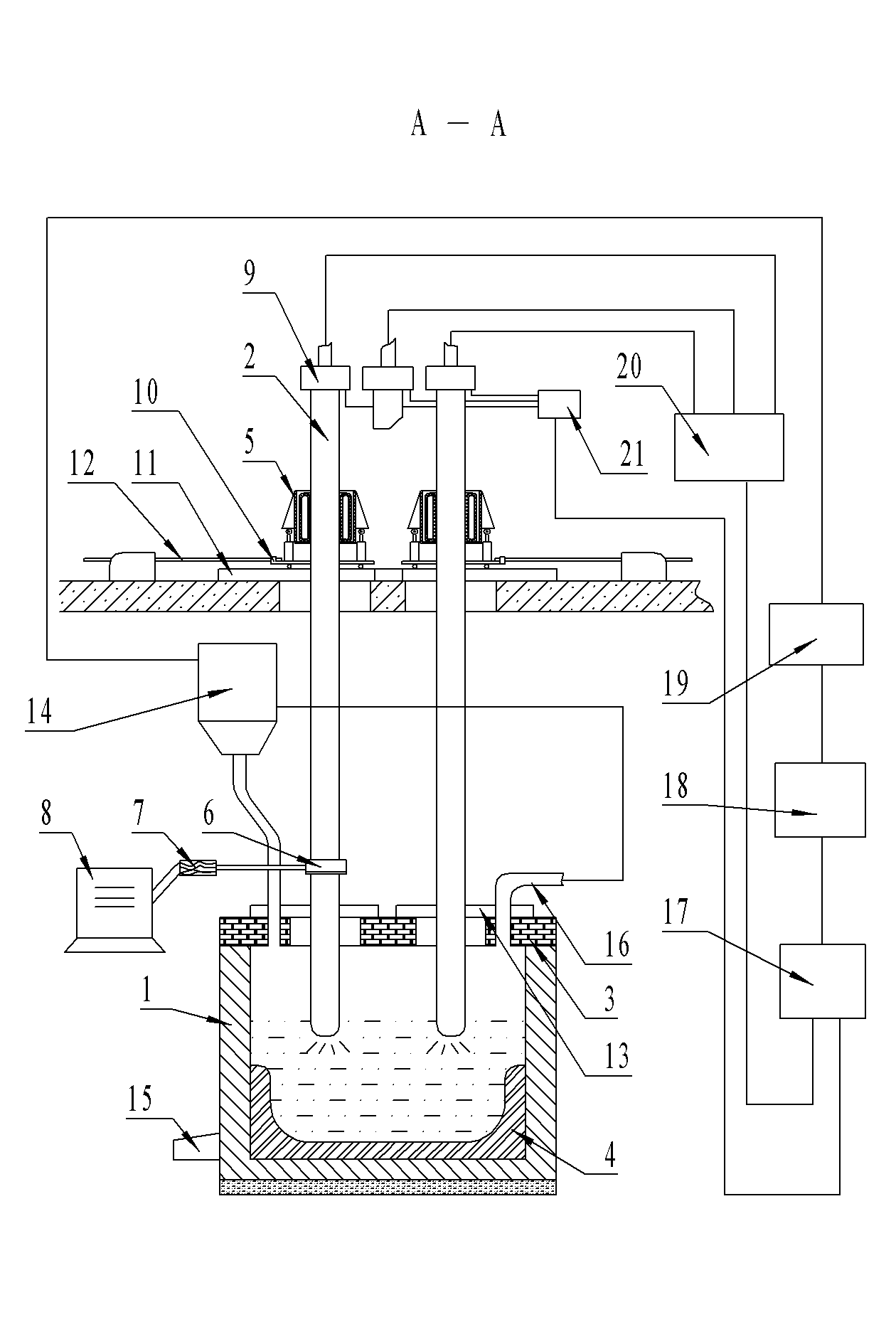

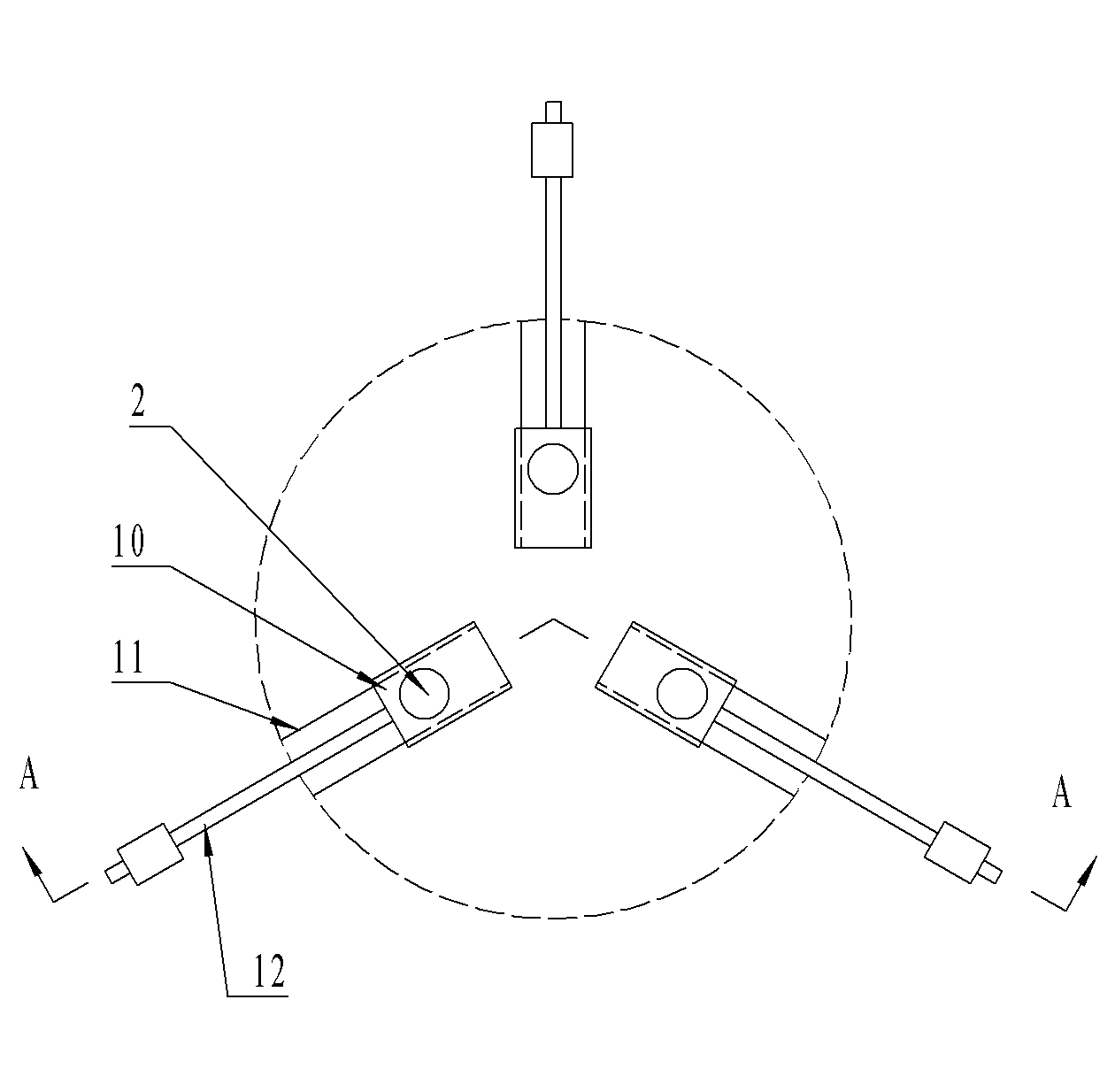

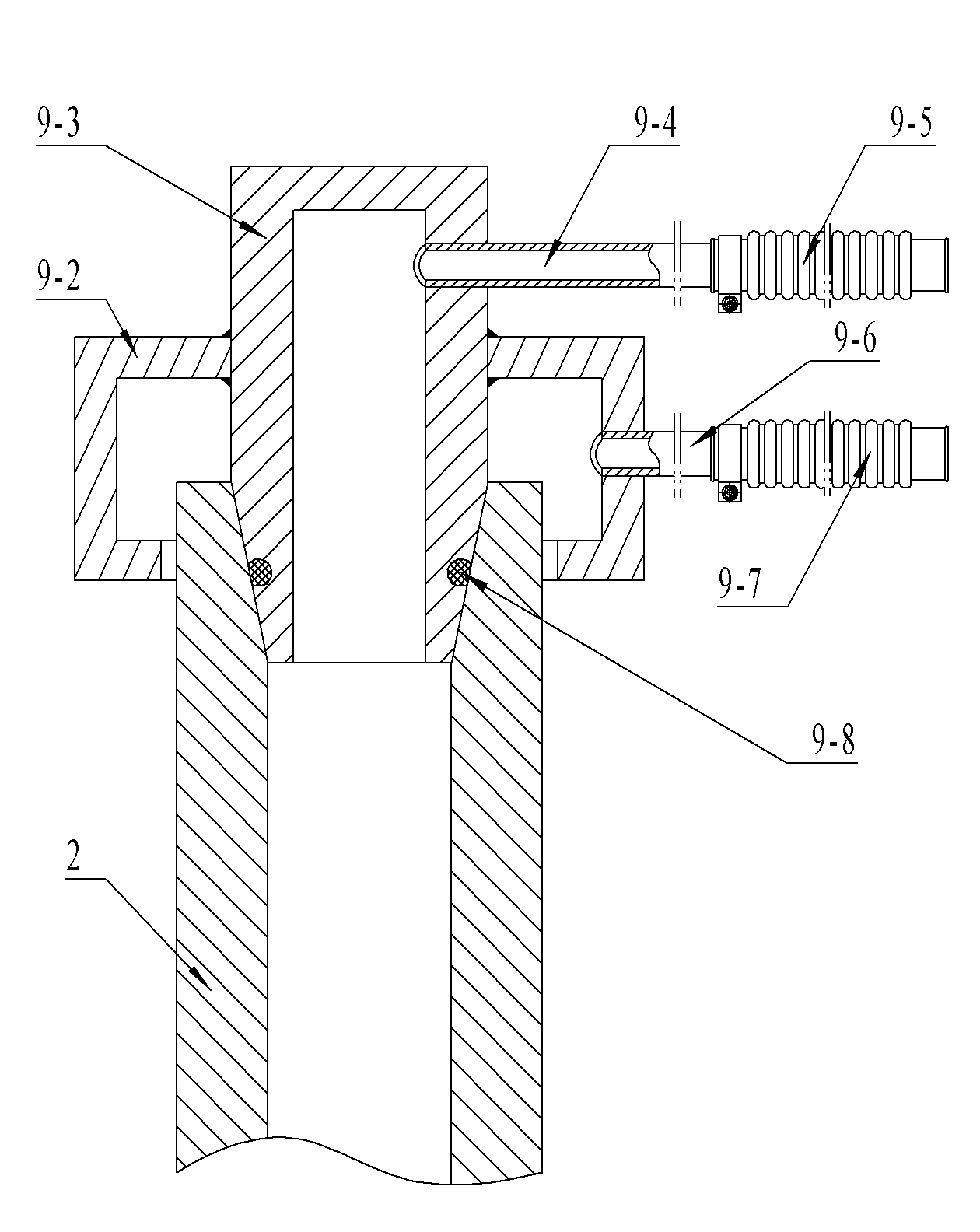

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0021] exist figure 1 In the furnace body 1, there are raw material ore and carbon smelting in the submerged arc furnace relying on the discharge heating of the electrode 2 of the submerged arc furnace. The furnace gas discharged from the submerged arc furnace enters the raw material preheater 14 through the exhaust port 16. The ore is preheated before entering the furnace, and the furnace gas is cooled at the same time; the cooled furnace gas is passed through the gas-water separator 19 to remove water, and then the dust is removed through the cyclone dust collector 18 . Carry out gas separation in the pressure swing adsorption device 17 of the furnace gas that removes moisture and dust, and the pressure swing adsorption process method that gas separation adopts concentrates and purifies carbon monoxide, the adsorption temperature is 20-55°C, and the adsorption p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com