Method for increasing color saturation of yellow fluorescent powder used for LED (light-emitting diode)

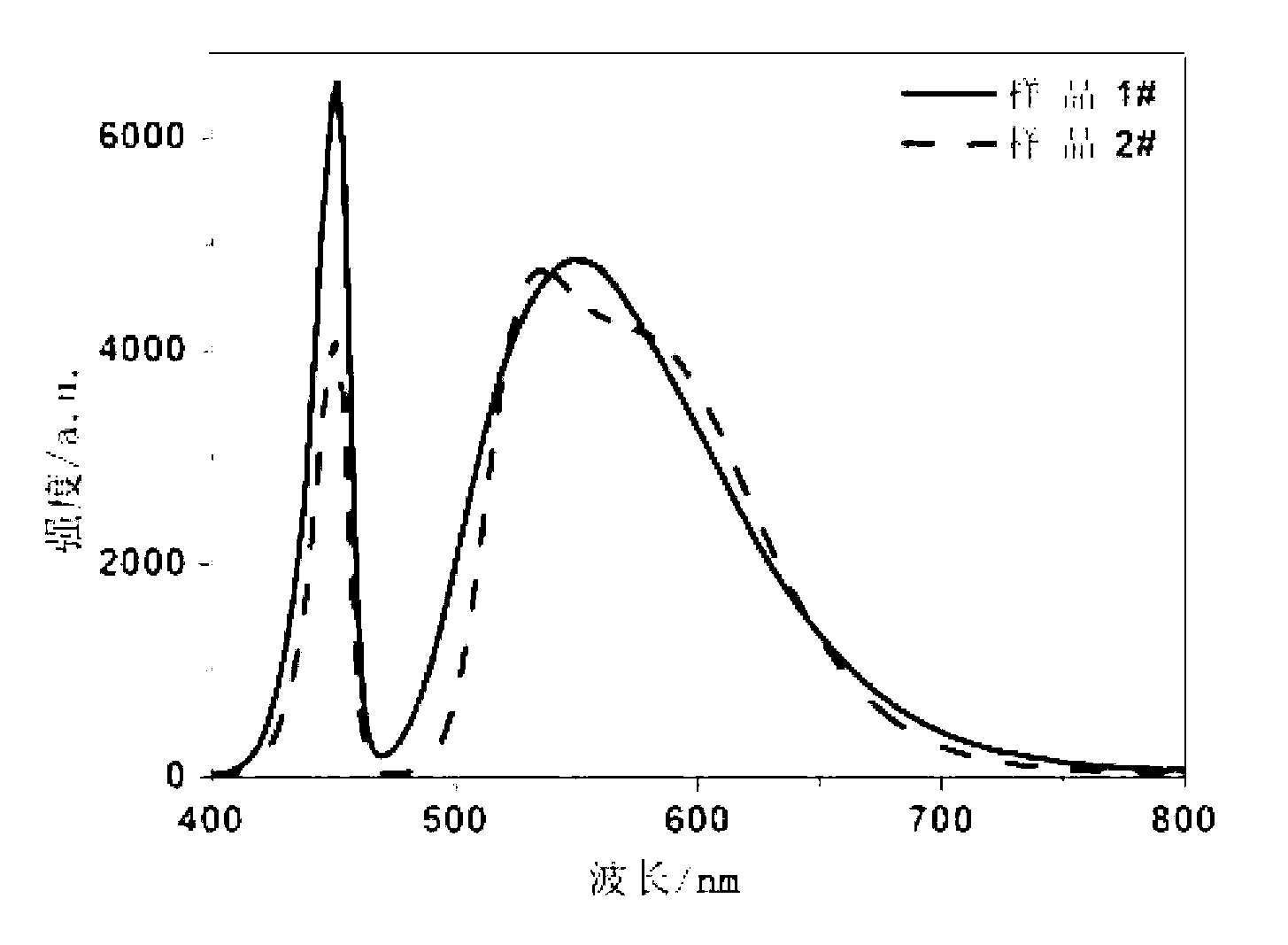

A technology of yellow phosphor and saturation, which is applied in the field of increasing the color saturation of yellow phosphor for LED, which can solve the problem of weakening of the luminous intensity of yellow phosphor, and achieve the effect of increased color saturation, regular appearance and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

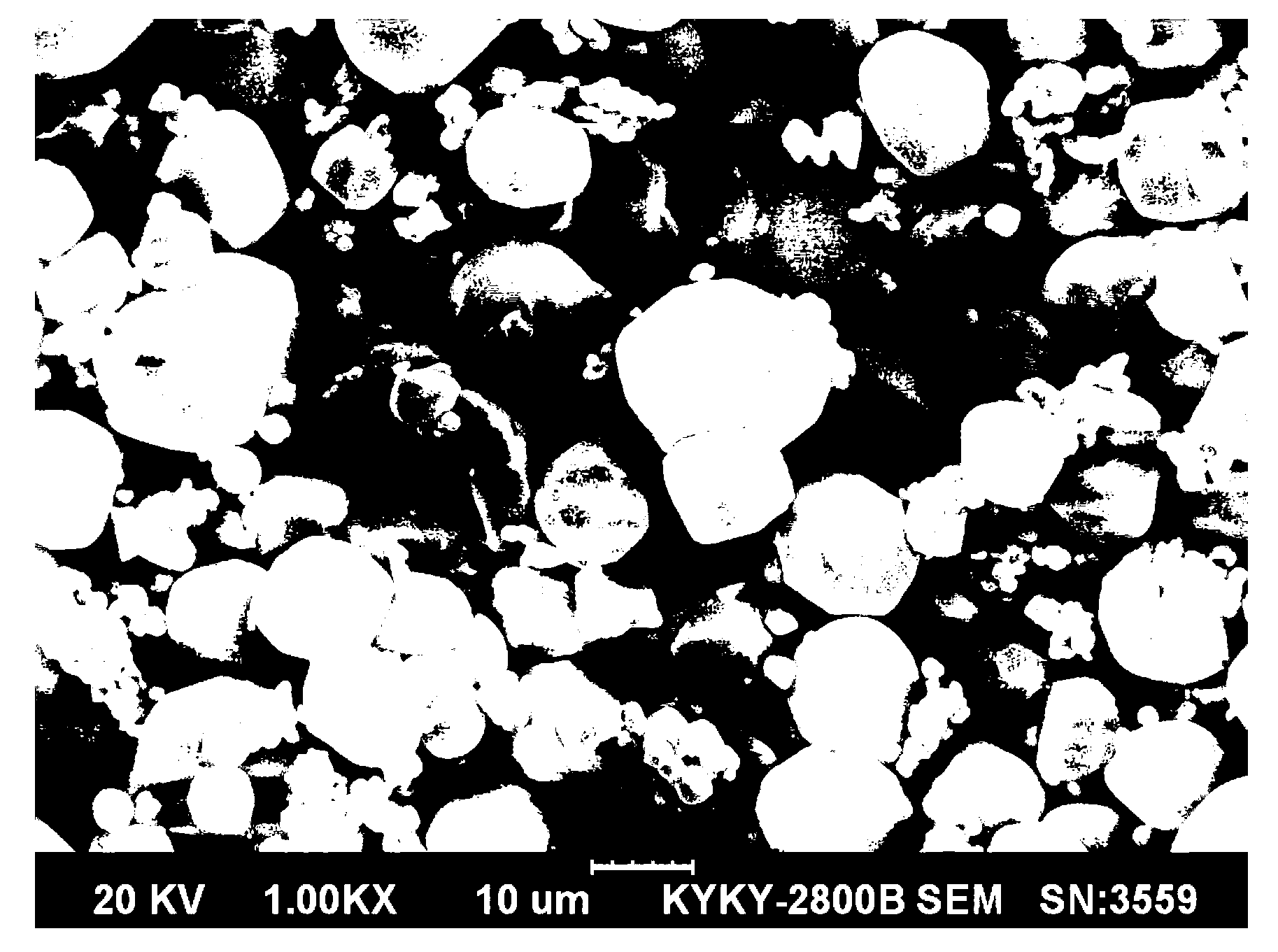

Embodiment 1

[0021] (1) Raw material selection: first use the air-flow grading sieve to classify the particle size of all raw materials, select the raw materials with a central particle diameter D50 of 5-6 μm, weigh the raw materials according to the stoichiometric ratio, and the matrix material is Y 2 o 3 、Al 2 o 3 , CeO 2 , Flux selection composite flux, that is, calcium carbonate (accounting for 0.5% by weight of the matrix raw material YAG), magnesium fluoride (accounting for 0.1% by weight of the matrix raw material YAG), boric acid (accounting for 0.1% by weight of the matrix raw material YAG) ;

[0022] (2) Mixing: Pour the above-mentioned raw materials into the mixing tank (the tank is filled with deionized water whose mass is 1 times that of the raw materials, and several agate balls of different sizes), mix the materials for 24 hours, take them out and ultrasonically disperse them at room temperature ;

[0023] (3) Burning: Sinter the uniformly mixed raw materials in a reduc...

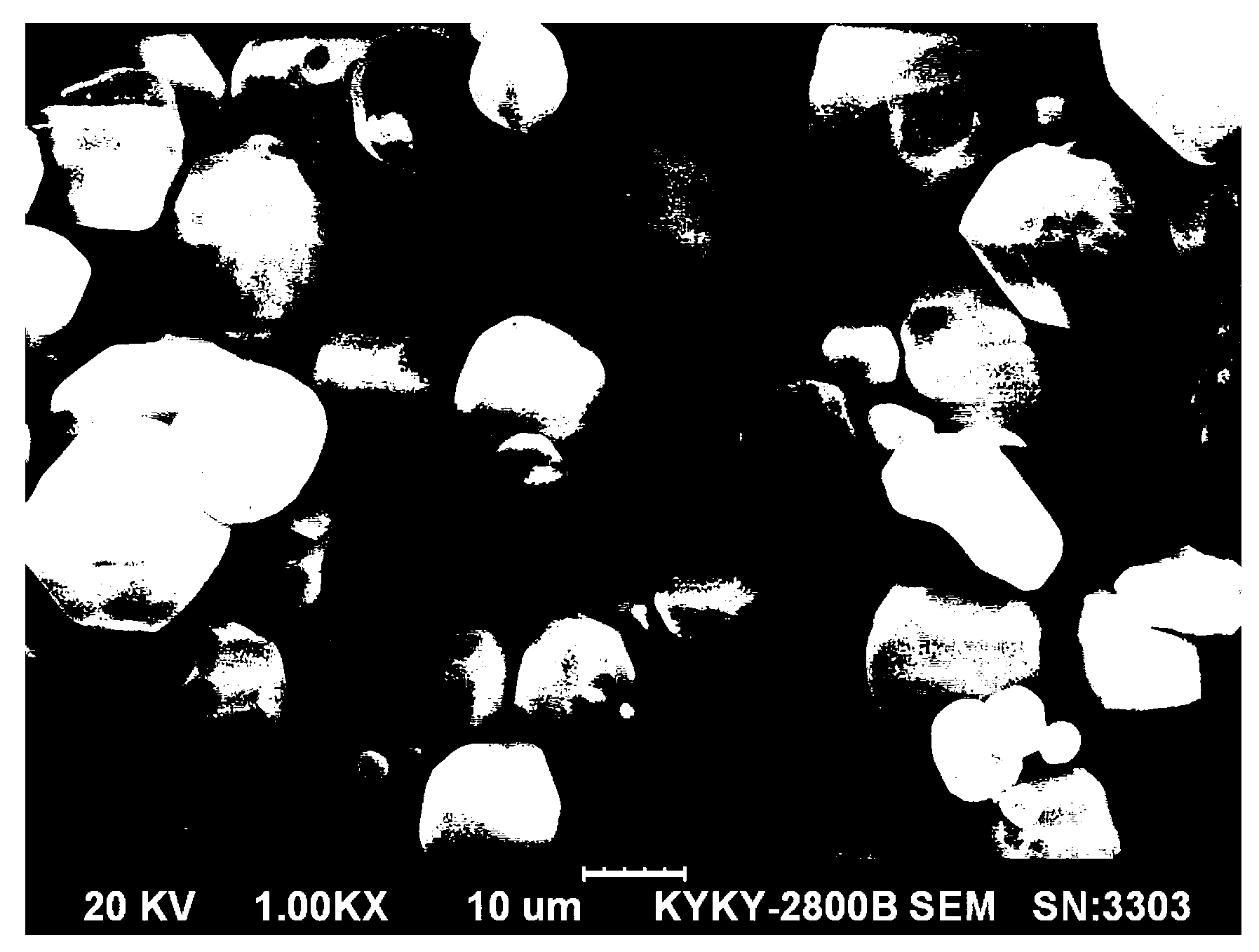

Embodiment 2

[0028] (1) Raw material selection: first use the air-flow grading sieve to classify the particle size of all raw materials, select the raw materials with a central particle diameter D50 of 5-6 μm, weigh the raw materials according to the stoichiometric ratio, and the matrix material is Y 2 o 3 、Al 2 o 3 , CeO 2 , Flux selection composite flux, namely calcium carbonate (accounting for 2% by weight of the matrix raw material YAG), magnesium fluoride (accounting for 0.8% by weight of the matrix raw material YAG), boric acid (accounting for 0.5% by weight of the matrix raw material YAG) ;

[0029] (2) Mixing: Pour the above raw materials into the mixing tank (the tank is filled with deionized water 1.5 times the quality of the raw materials, and a number of agate balls of different sizes), mix for 24 hours, take out and ultrasonically disperse at room temperature ;

[0030] (3) Burning: Sinter the uniformly mixed raw materials in a reducing atmosphere at 1450oC for 6 hours; ...

Embodiment 3

[0035] (1) Raw material selection: first use the air-flow grading sieve to classify the particle size of all raw materials, select the raw materials with a central particle diameter D50 of 5-6 μm, weigh the raw materials according to the stoichiometric ratio, and the matrix material is Y 2 o 3 、Al 2 o 3 , CeO 2 , Flux selection composite flux, that is, calcium carbonate (accounting for 5% by weight of the matrix raw material YAG), magnesium fluoride (accounting for 2% by weight of the matrix raw material YAG), boric acid (accounting for 1% by weight of the matrix raw material YAG) ;

[0036] (2) Mixing: Pour the above raw materials into the mixing tank (the tank is filled with deionized water twice the quality of the raw materials, and a number of agate balls of different sizes), mix for 24 hours, take out and ultrasonically disperse at room temperature ;

[0037](3) Burning: Sinter the uniformly mixed raw materials in a reducing atmosphere at 1250oC for 10 hours;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com