Mirror silver ink and preparation method thereof

A technology of mirror silver and ink, applied in the field of ink, can solve the problems of large corrosive substances, pollution, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of mirror silver ink

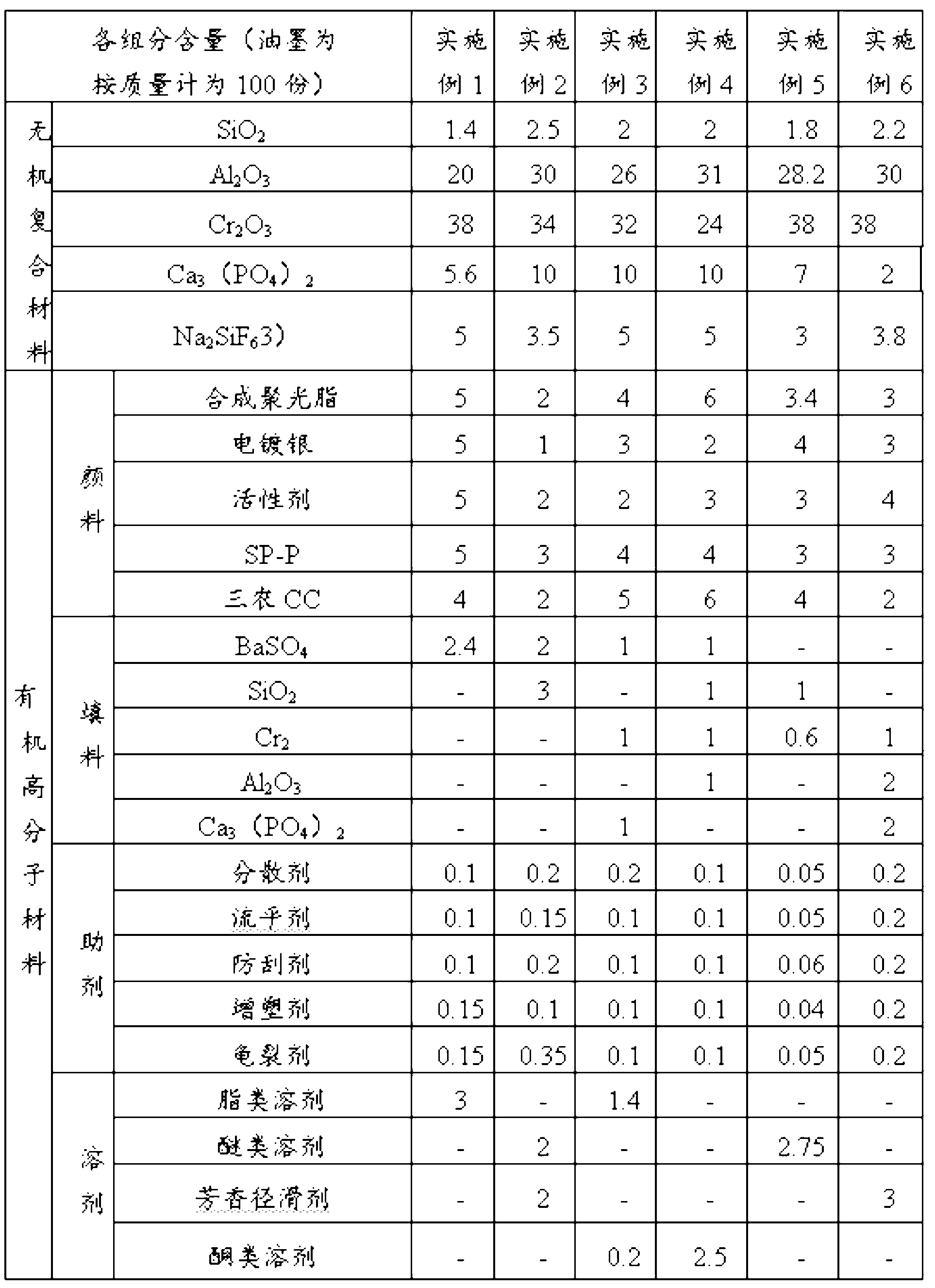

[0024] Step 1, by the content of each component specified in Table 1, the following components: SiO 2 、Al 2 o 3 、Cr 2 o 3 , Ca 3 (PO 4 ) 2 、Na 2 SiF 6 Put it in an environment of 200-300°C and grind for X-Y minutes to form uniform inorganic mixed particles, and cool naturally to room temperature;

[0025] Step 2, pulverizing and grinding the cooled inorganic mixture particles into a powdered inorganic mixture with a particle size of 6 μm-10 μm;

[0026] Step 3. According to the content of each component specified in Table 1, add the following components: pigments, fillers, additives, and solvents to the powdered inorganic mixture, and stir evenly at 20-30°C, and then use The grinding process grinds into a fluid mixture with a particle size of 6 μm-10 μm, and the fluid mixture is mirror silver ink.

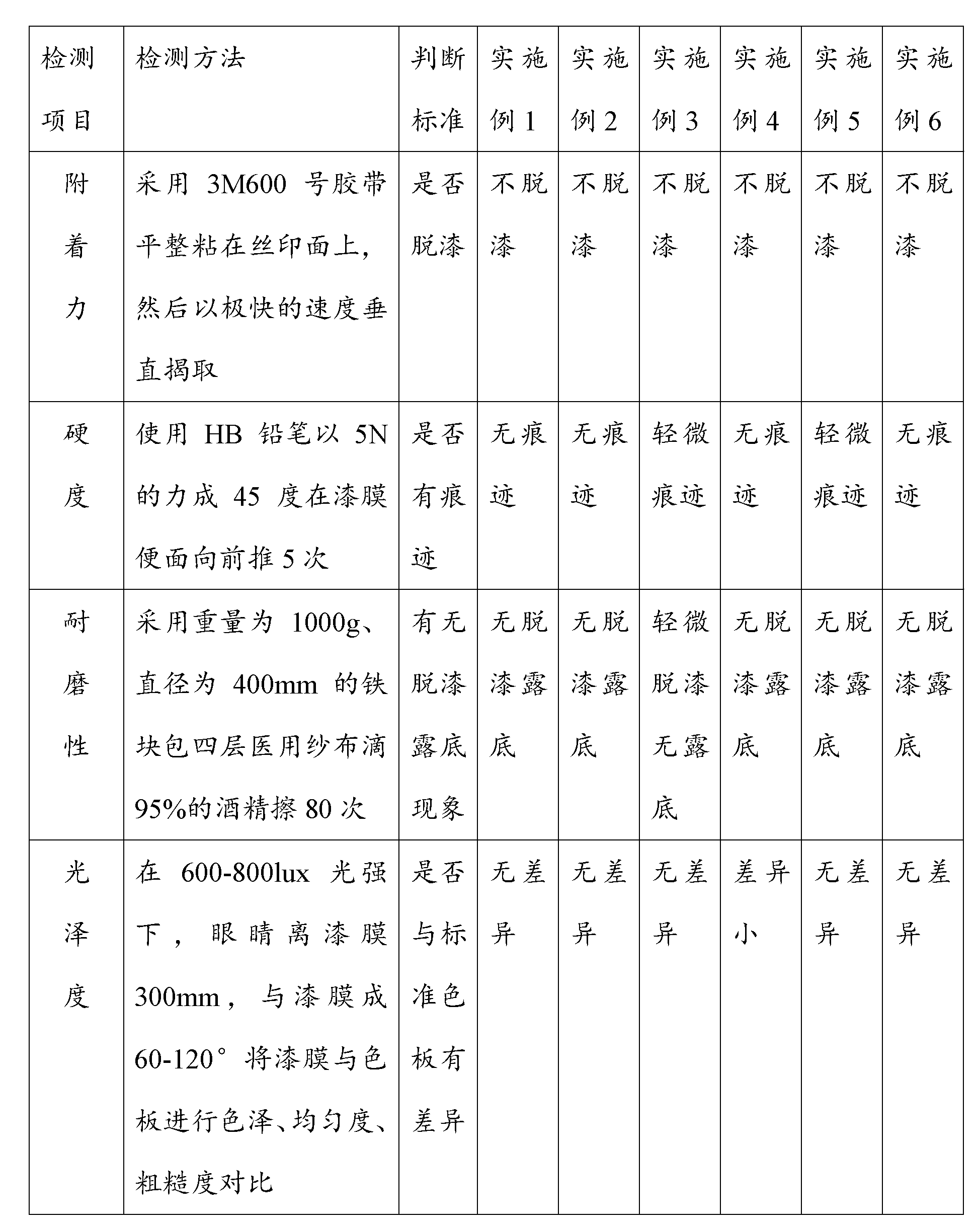

[0027] 2. Use and performance test of mirror silver ink

[0028] Step 1. Provide a plastic part (TV panel), silk screen fix...

Embodiment 2

[0033] Repeat the method of Example 1 according to the content of each component specified in Table 1, and the surface brightness, silver color, and metallic texture of the plastic part printed by the silk screen of this example; Temperature tolerance, the measurement results are shown in Table 2.

Embodiment 3

[0035] Repeat the method of Example 1 according to the content of each component specified in Table 1, and the surface brightness, silver color, and metallic texture of the plastic part printed by the silk screen of this example; Temperature tolerance, the measurement results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com