Oil-water separation and oil output remote quantitative multi-dimensional monitoring system

A monitoring system and oil-water separation technology, applied in separation methods, liquid separation, electrical program control, etc., can solve the problems of oil layer blocking pipelines, easy oxidation, and odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The method of the present invention will be described in further detail below in conjunction with the specific embodiments of the accompanying drawings.

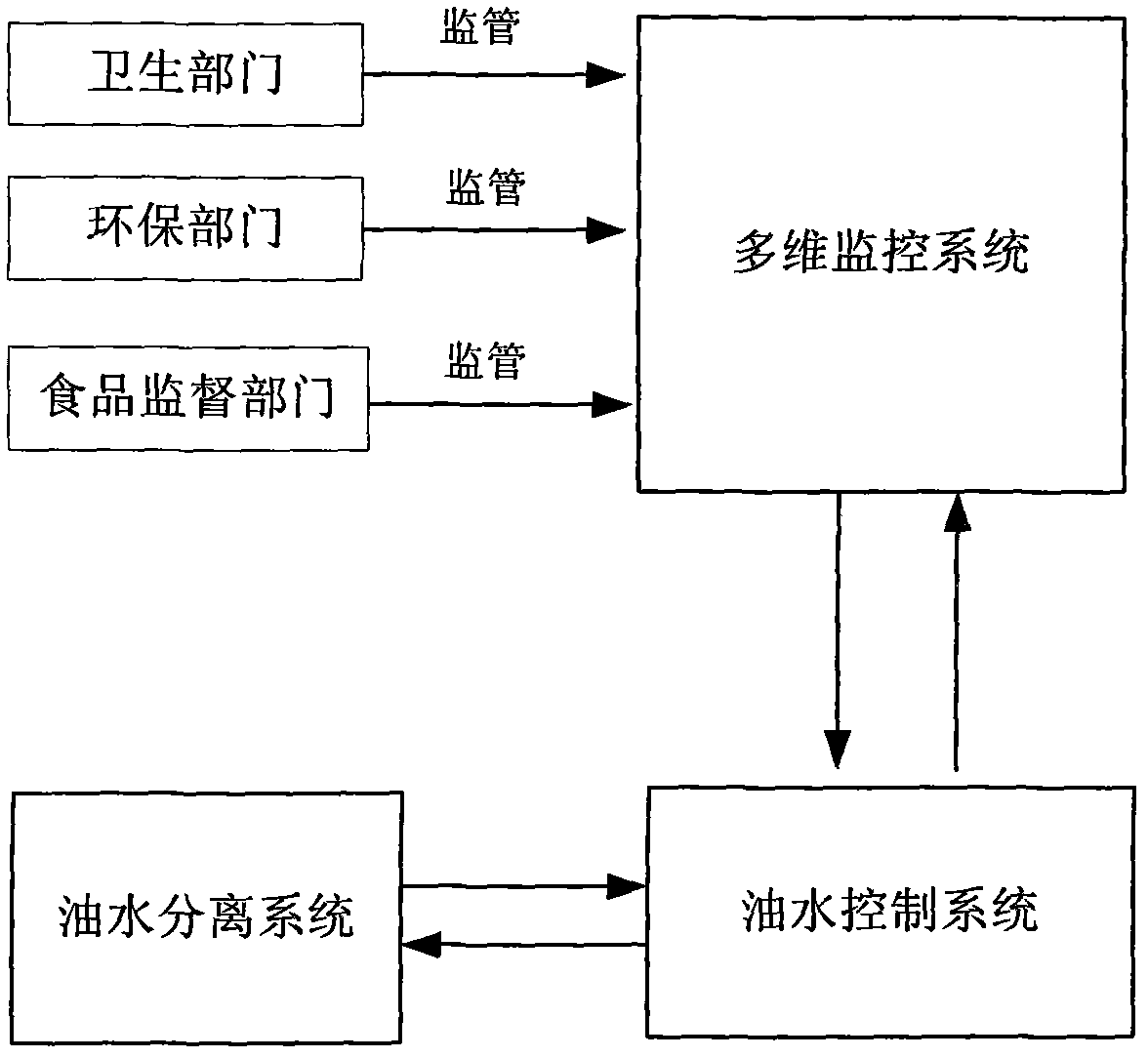

[0045] figure 1 It is a structural schematic diagram of the system of the present invention.

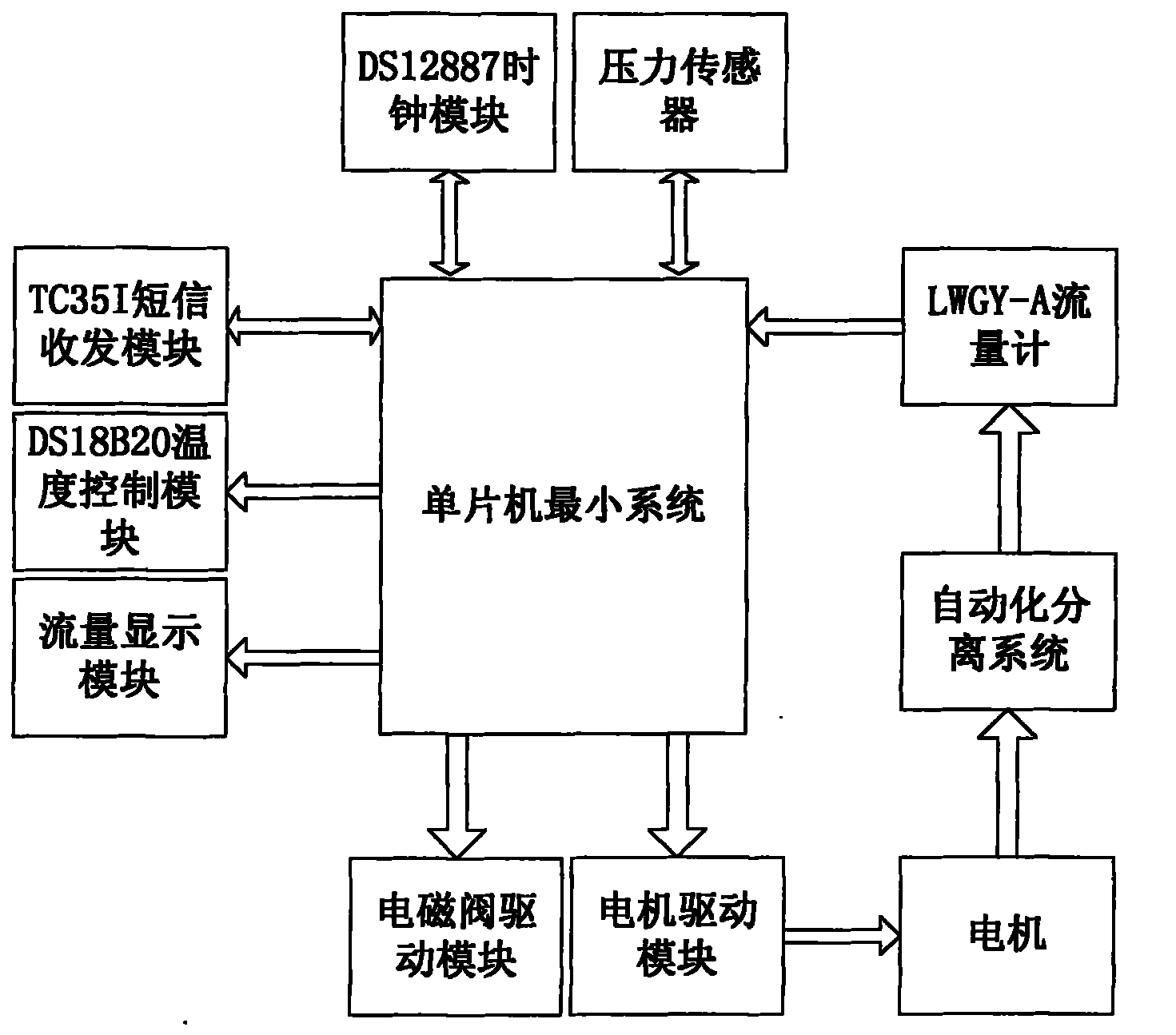

[0046] The automatic oil-water separation system is responsible for automatic and efficient separation of oil and water; the oil-water control system uses various pressure sensors and flow meters to extract relevant data and signals from the automatic oil-water separation system, and after receiving the control signal of the multi-dimensional monitoring system, drives the relevant Executive components, such as solenoid valves and motors, realize the control of the automatic oil-water separation system; the multi-dimensional monitoring system is responsible for collecting, monitoring, reporting and storing real-time data of the automatic oil-water separation system through the Internet / GSM. Through the monitoring data, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com