Method and system for preparing relief painting and relief painting

A production method and technology of embossing, applied in the fields of embossed paintings and embossed paintings, can solve problems such as the inability to form relief paintings in mass production, and achieve the effects of rich picture colors, saving production costs, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

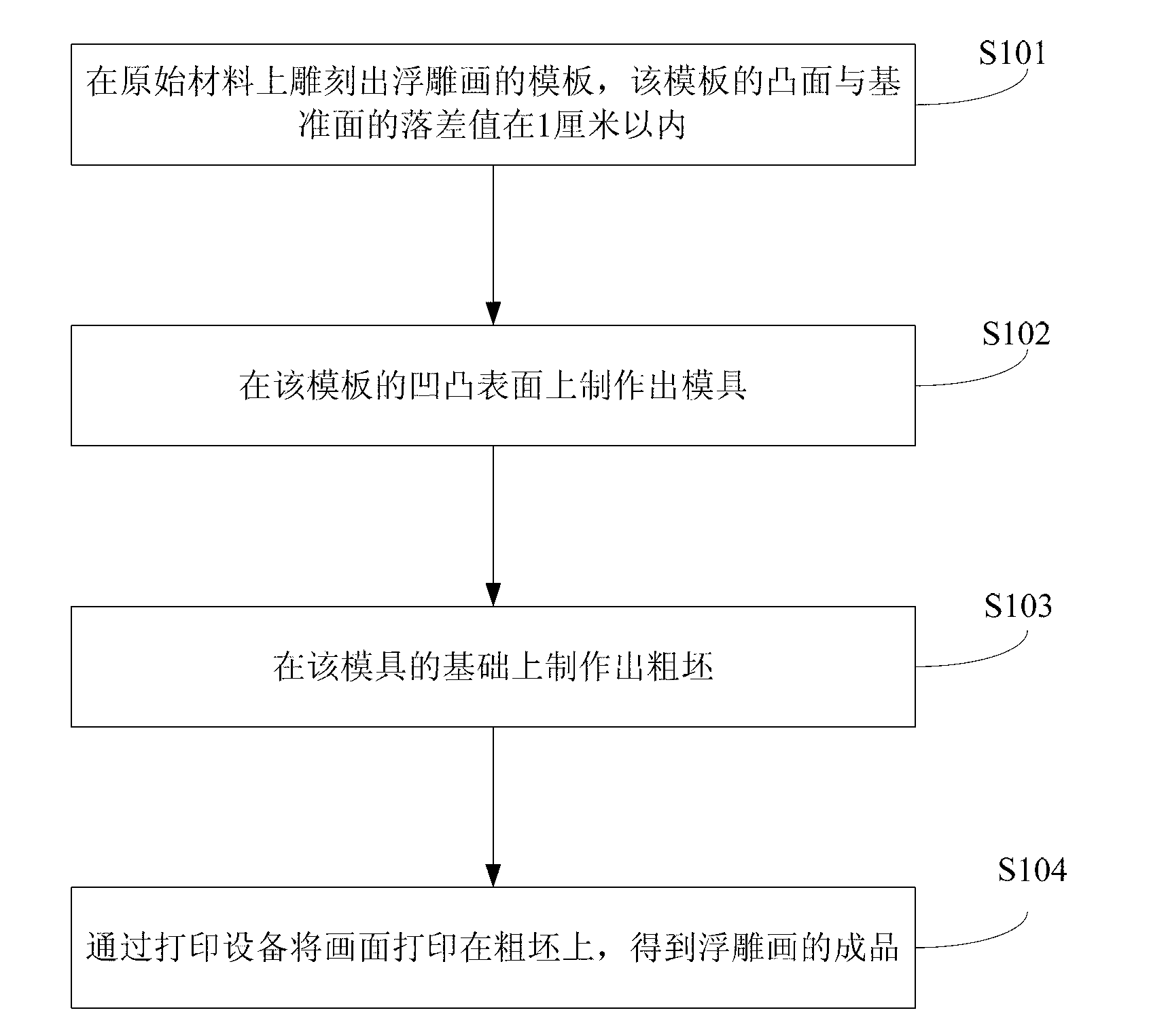

[0055] Embodiment 1 of the present invention provides a kind of relief painting making method, see figure 1 ,include:

[0056] Step S101: Carving out a relief painting template on the original material, the difference between the convex surface of the template and the reference plane is within 1 cm;

[0057] Step S102: making a mold on the concave-convex surface of the template;

[0058] Step S103: making a rough blank on the basis of the mould;

[0059] Step S104: Printing a picture on the rough blank by a printing device to obtain the finished relief painting.

[0060] In the method for making a relief painting provided by Embodiment 1 of the present invention, the drop value between the convex surface of the template and the reference surface is within 1 centimeter, and then after the mold and the rough blank are made on the basis of the template, the convex surface of the rough blank and the rough blank The drop value of the reference plane is also within 1 cm, which is...

Embodiment 2

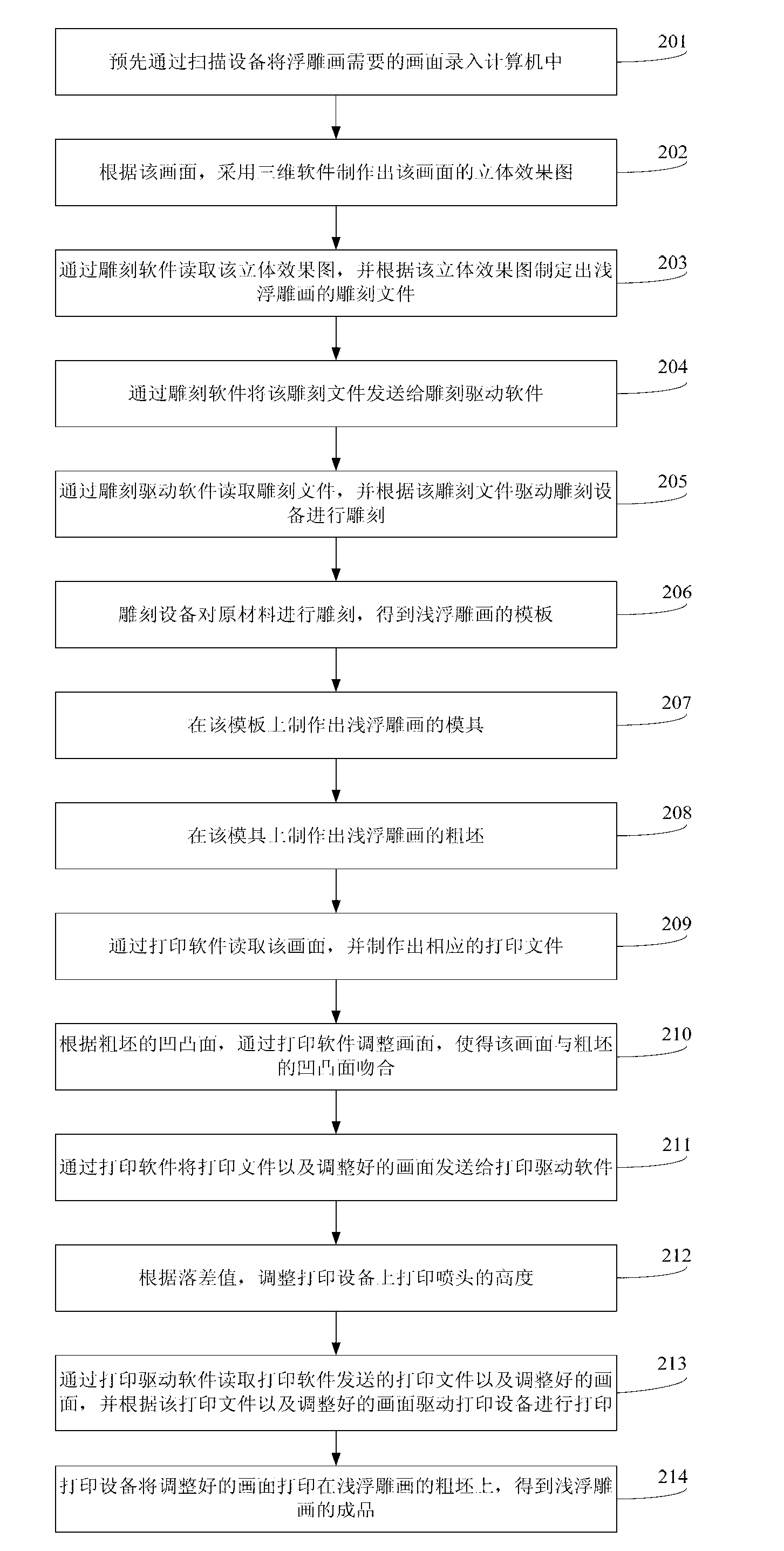

[0063] Embodiment 2 of the present invention provides another method for making relief paintings, see figure 2 , including the following steps:

[0064] Step 201: Pre-enter the images required for the relief painting into the computer through the scanning device;

[0065] Specifically, in this embodiment, the picture is generally a two-dimensional plane picture;

[0066] Step 202: According to the picture entered into the computer, use 3D software to make a three-dimensional rendering of the picture;

[0067] Wherein, the drop value between the convex surface and the reference plane on the stereoscopic rendering is set within 1 cm;

[0068] Preferably, in this embodiment, the three-dimensional software is 3Dmax software, in this software, set the drop value between the convex surface and the reference plane on the three-dimensional effect map of the picture to be within the range of 0.3-0.9 centimeters;

[0069] At the same time, because the drop value is small, in order t...

Embodiment 1

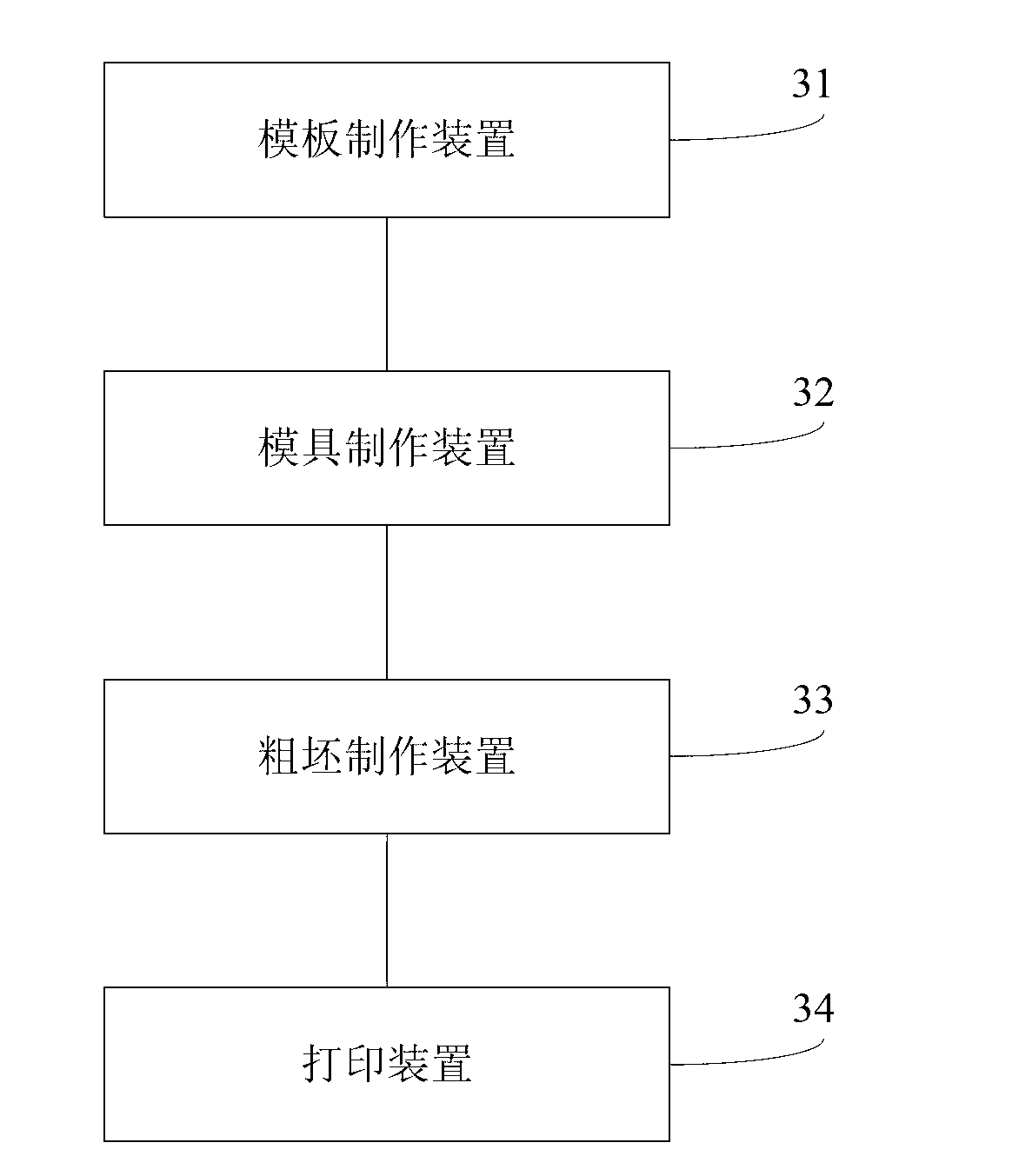

[0103] For the first embodiment, the third embodiment of the present invention provides a relief painting production system, see image 3 ,include:

[0104] The template making device 31 is used to carve a template for relief painting on the original material, and the drop value between the convex surface of the template and the reference plane is within 1 centimeter;

[0105] Mold making device 32 is used to make a mold on the concave-convex surface of the template;

[0106] Rough blank making device 33, for making rough blank on the basis of described mould;

[0107] The printing device 34 is used to print the picture on the rough blank by a printing device, so as to obtain the finished product of the relief painting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com