Tool for combined welding of skirt board frame of rail vehicle

A rail vehicle and skirt plate technology is applied in the field of welding tooling for rail vehicle skirt plate and frame combination, which can solve the problems of large size deviation of skirt frame assembly, easy occurrence of wrong side welding deformation, many welding processes, etc. The effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

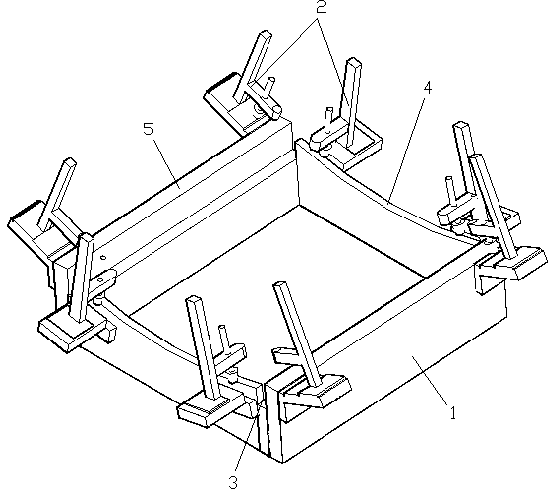

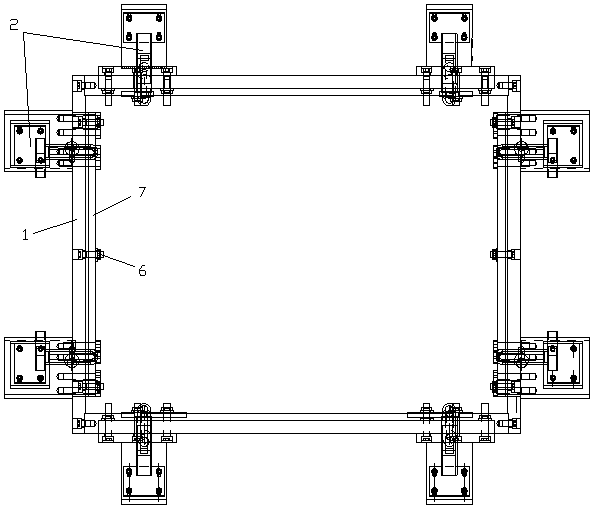

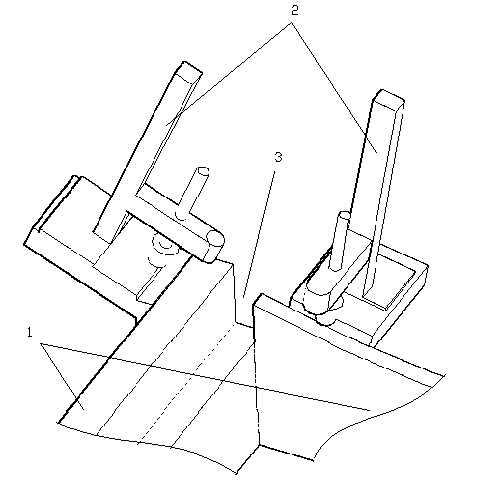

[0015] Such as figure 1 , 2 As shown in and 3, the tooling for combined welding of the rail vehicle skirt panel frame in this embodiment includes a rectangular support frame 1 for supporting and positioning the skirt panel frame and a chuck 2 for fixing the skirt panel, and four of the rectangular support frame 1 A window 3 for welding operation is provided at the upper end of the rectangular corner, and a chuck 2 is provided on both outer surfaces of each rectangular corner.

[0016] During welding, place the side plates forming the skirt plate frame on the end faces of the supporting side plates corresponding to the rectangular support frame 1, and press the skirt plate frame side plates tightly through the clamps arranged at the corners of the rectangular frame 1. Since the four rectangular corners of the rectangular support frame 1 are provided with windows 3 for welding operations, the operator can conveniently perform welding operations without being interfered by the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com