Molybdenum plate roll cold rolling equipment

A coil and equipment technology, applied in the direction of metal rolling, etc., can solve the problems of large material cutting loss, small product unit weight, and low utilization rate of single sheet materials, so as to achieve small cutting loss and reduce The effect of increasing the number of times of annealing and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

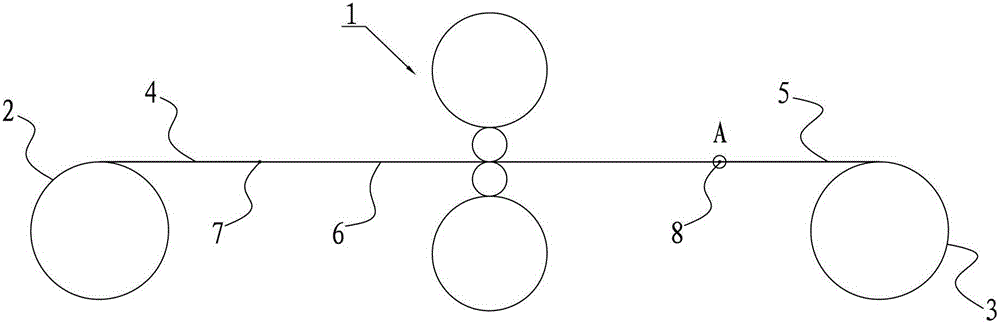

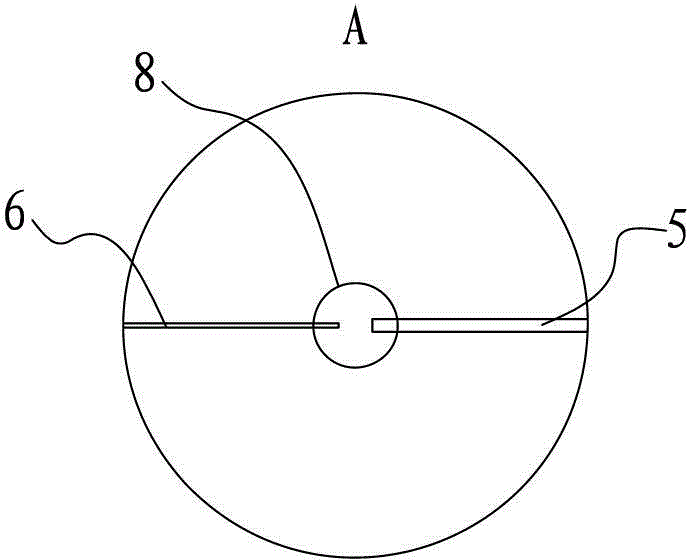

[0013] see figure 1 and figure 2 , This embodiment provides a molybdenum plate and coil cold rolling equipment, which is based on a common cold rolling mill, and is composed of two sets of retracting and unwinding coiling devices with tension. details as follows:

[0014] The cold rolling mill has rolls 1 arranged in pairs up and down. The first tension roller 2 and the second tension roller 3 with tension are respectively arranged on the opposite two sides of the roll 1, and the first tension roller 2 and the second tension roller 3 are respectively wound with a rigid first tension roller. A leader 4 and a rigid second leader 5. The first guide strip 4 and the second guide strip 5 are further connected to the molybdenum plate through a first elastic connector 7 and a second elastic connector 8 respectively. In this way, the molybdenum plate 6 is connected with the tension roller through the leader belt and the connector. When the molybdenum plate is fed to the lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com