Filtering device

A filter device and filter medium technology, which is applied in the direction of filter separation, gravity filter, loose filter material filter, etc., can solve the problems of low filtration speed, reduced filter area of filter medium, and inapplicability, so as to avoid clogging of filter cloth , good purification effect and strong sewage absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

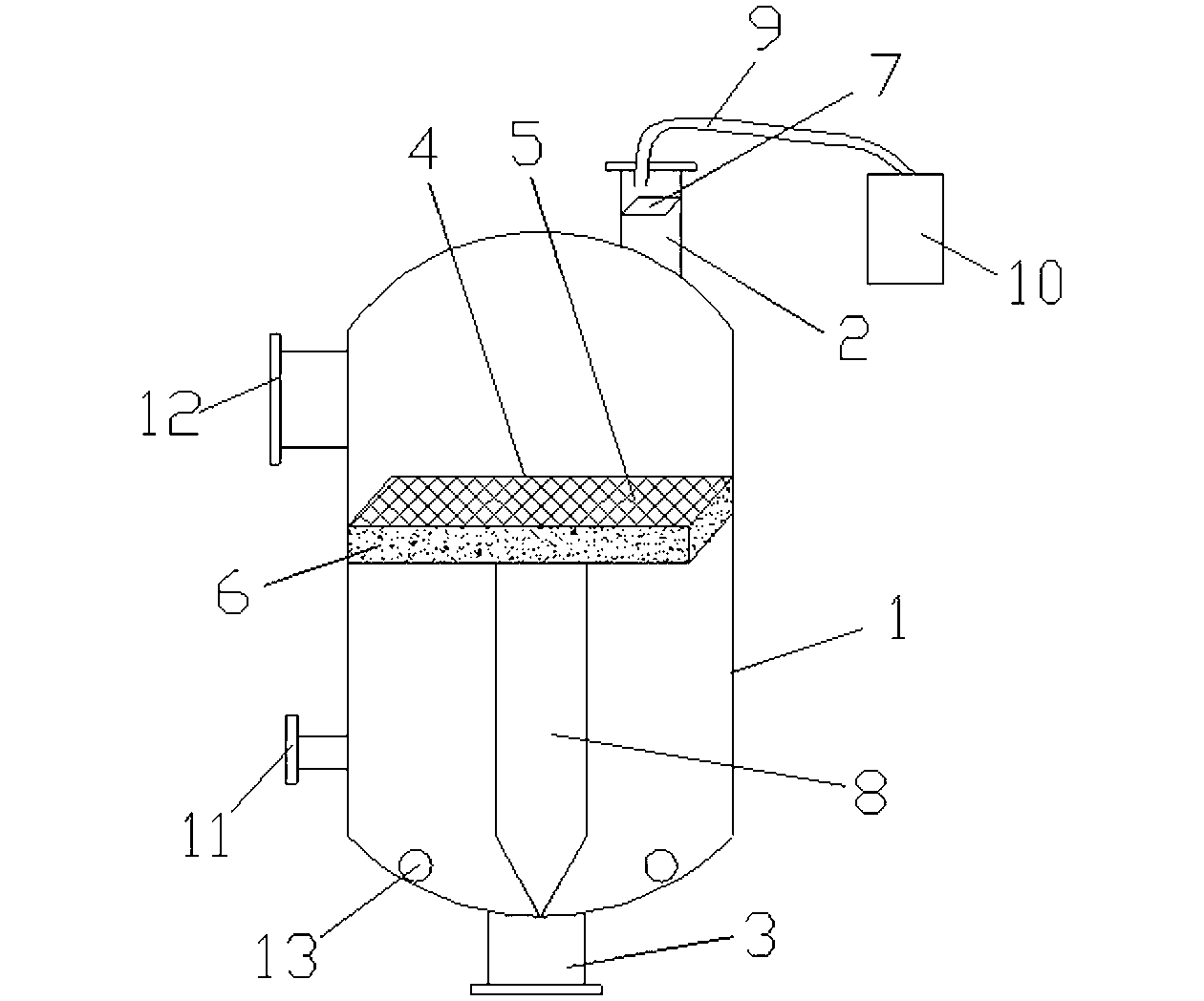

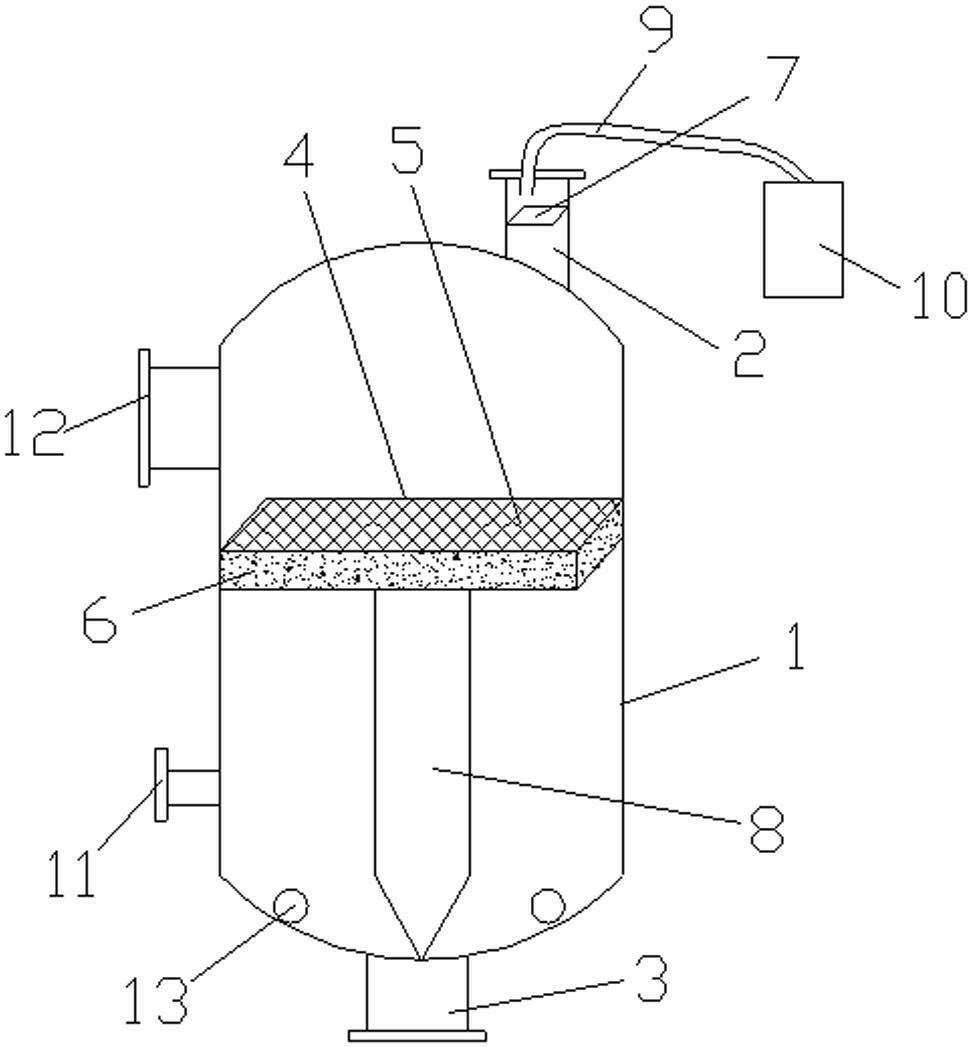

[0013] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0014] Such as figure 1 As shown, a filter device includes a housing 1, the top and bottom of the housing 1 are respectively provided with a water inlet 2 and a water outlet 3, and the inner wall of the housing 1 is provided with a double-layer filter plate 4, and the double-layer filter The plate 4 is provided with a mesh hole 5, a filter medium 6 is arranged between the double-layer filter plates 4, a filter cloth 7 is arranged at the water inlet 2, and a filter element 8 is arranged at the lower part of the double-layer filter plate 4, and the filter element The lower part of 8 is conical, and the filter element 8 communicates with the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com