Rolling tube type Chinese chestnut opening machine

A technology of open-cutting machine and drum type, which is applied in the field of drum-type chestnut opening machine, can solve the problems of high labor intensity and low labor efficiency, achieve the effect of reducing labor intensity, overcoming high labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

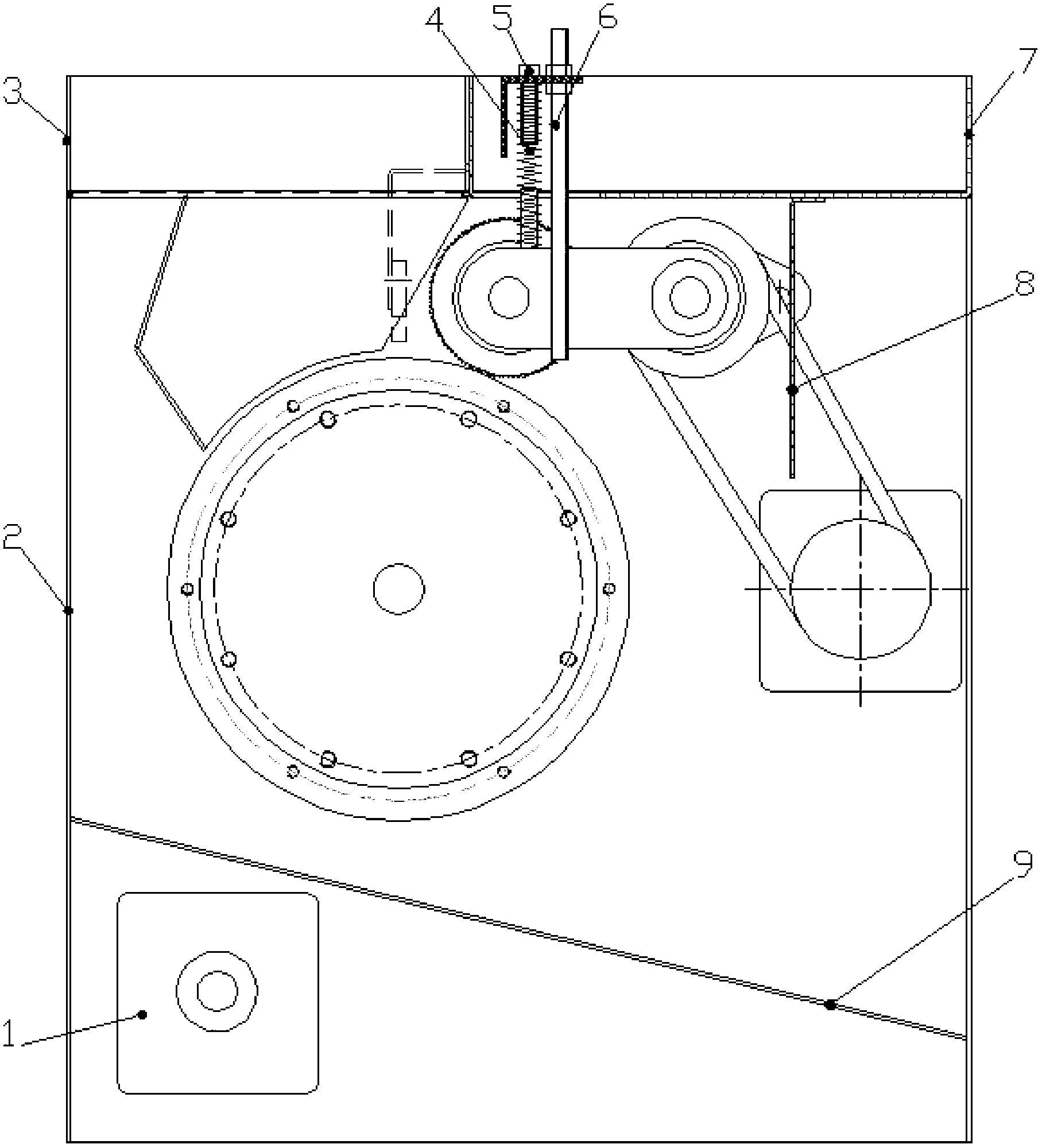

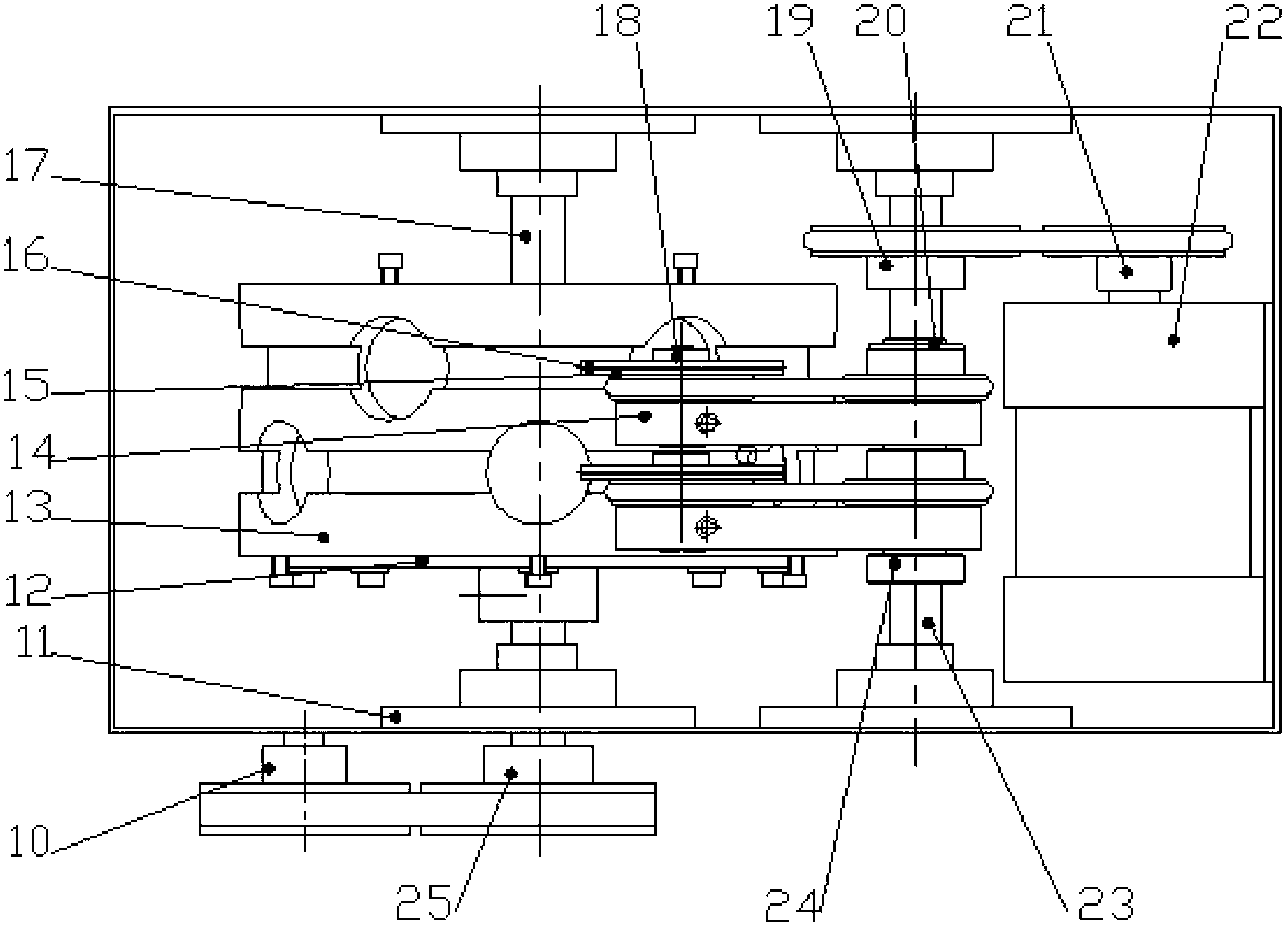

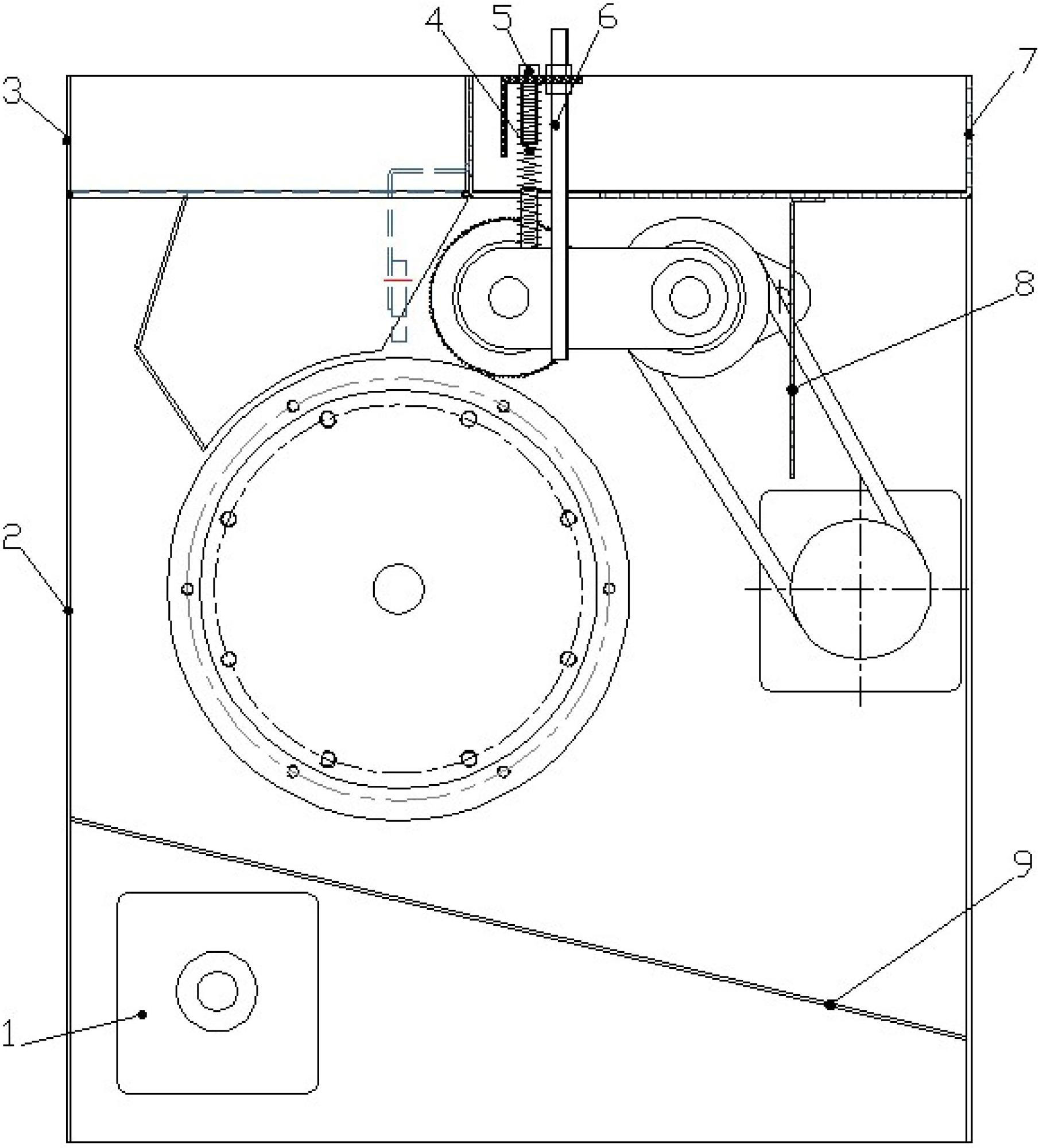

[0014] Such as figure 1 Shown, the present invention comprises housing 2, cylinder 13, blade 16, motor I22, motor II1, belt pulley A10, belt pulley B25, belt pulley I, belt pulley II19, belt pulley III20 and belt pulley IV15, and corresponding cylinder 13 places are opened on the housing 2 There are holes, and the drum 13 is fixed in the housing 2 through the drum flange 12, the drum shaft 17 and the bearing seat 11. One end of the drum shaft 17 protrudes out of the housing 2, and the end is equipped with a pulley B25. The pulley B25 passes through the belt and the motor. The pulley A10 on the II1 is connected, the blade 16 is fixedly connected with the pulley IV15 through the blade pressure plate 18, and is fixed in the housing 2 through the connecting plate 14, the pulley III20, the retaining sleeve 24, the connecting plate shaft 23 and the bearing seat, and the tip of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com