Method for increasing mine tailing storage reserve based on designed storage capacity

A technology for tailings ponds and tailings, which is applied in the fields of mining and expansion of mine tailings ponds. It can solve the problems of huge investment, large footprint of tailings ponds, and increased transportation costs of tailings mud, so as to avoid investment and land occupation. , save land resources and production costs, simple and efficient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

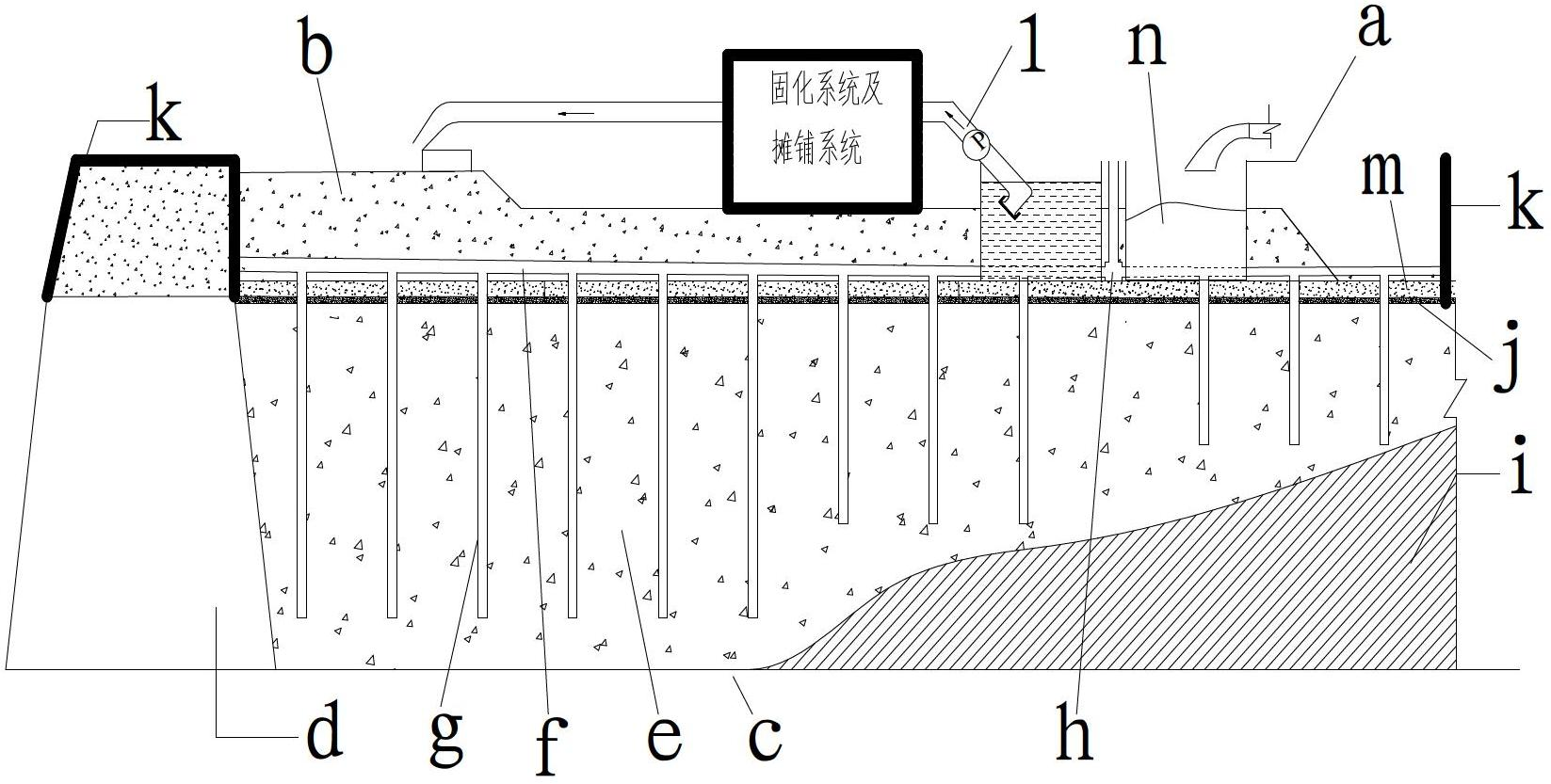

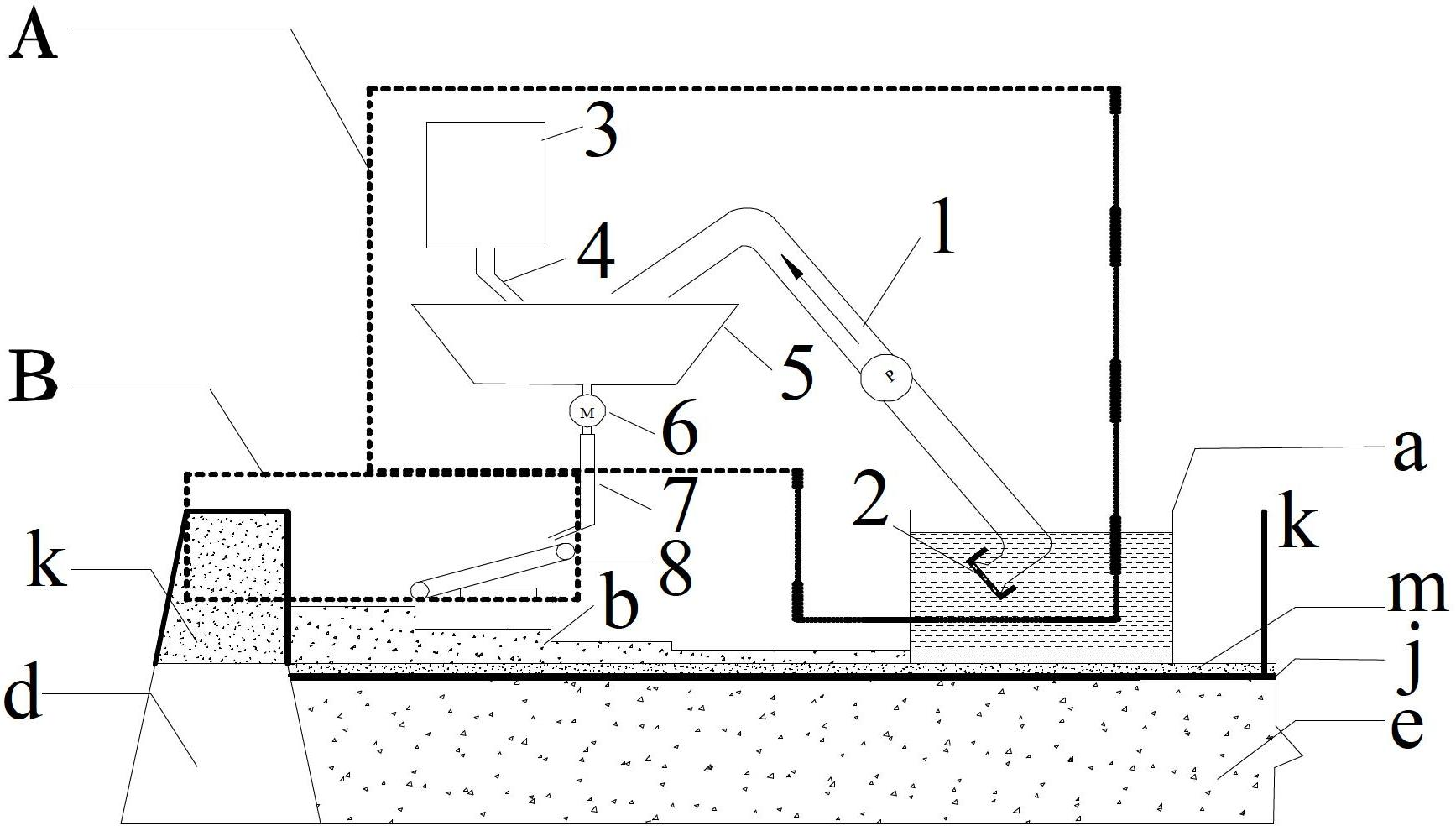

[0047] A bauxite tailings pond that is about to reach the designed storage capacity has a roof area of 100 hectares, the original tailings dam height is 30m, and the daily discharge of tailings slurry is 15,000 m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0048] According to the plane shape and convenient construction of the original tailings pond c, the original tailings pond is divided into four tailings pond areas, and the original tailings mud e in each tailings pond area has a small surface density and cannot meet the bearing capacity Subsequent paving is required for denser consolidated tailings soils. For each tailings pond area of the tailings pond, follow-up operations shall be carried out sequentially as follows:

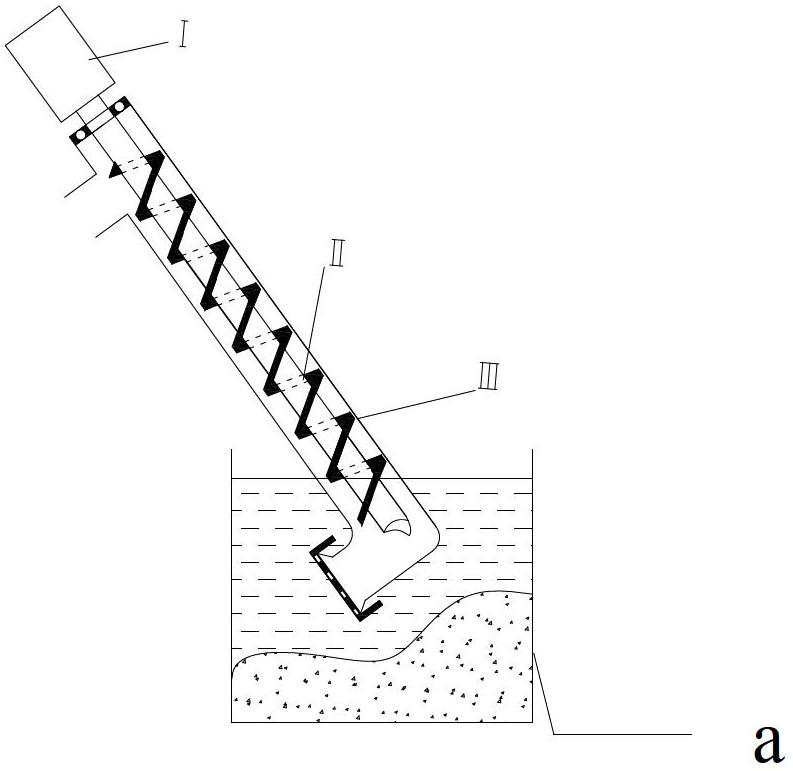

[0049] ① Lay a layer of isolation layer j made of bamboo on the surface of the original tailings mud layer, and then use a pumping device to take out part of the original tailings...

Embodiment 2

[0059] An iron ore tailings pond that is about to reach the design capacity, the top surface area of the pond is 150 hectares, the original tailings dam height is 38m, and the daily discharge of tailings slurry is 30,000m 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0060] According to the plane shape of the existing tailings pond, the tailings pond is divided into three tailings pond areas. The original tailings mud e of each tailings pond area has a relatively high surface density, and the bearing capacity can meet the density of subsequent paving. Large solidified tailings soil requirements. Carry out follow-up operations for each area sequentially as follows:

[0061] ① Take out part of the original tailings slurry e directly from the tailings pond area by pumping device, and add 6% (mass percentage) of ordinary Portland cement and lime mixture as a curing agent (ordinary Portland cement and lime The...

Embodiment 3

[0071] A copper mine tailings pond that is about to reach the design capacity, the top surface area of the pond is 60 hectares, the original tailings dam height is 30m, and the daily discharge of tailings mud is 9,000 m3 3 , using the method provided by the invention to increase storage capacity. The specific method is as follows:

[0072] According to the density and bearing capacity of the tailings slurry on the surface of the original tailings pond c and the plane shape of the original tailings pond c, the tailings pond is divided into three tailings pond areas, of which two tailings pond areas The surface density of the original tailings mud e is small, and its bearing capacity cannot meet the requirements of the solidified tailings soil with a higher density for subsequent paving. The strength can meet the requirements of the solidified tailings soil with higher density for subsequent paving, and follow-up operations are carried out for each tailings pond area in seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com