Interception and drainage power consolidation soft foundation treatment method

A dynamic consolidation, soft foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as ineffective precipitation and dissipation of pore water pressure, difficulty in meeting control requirements for groundwater levels, and reduce risks and costs. , controllable cost and quality, environmental protection and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

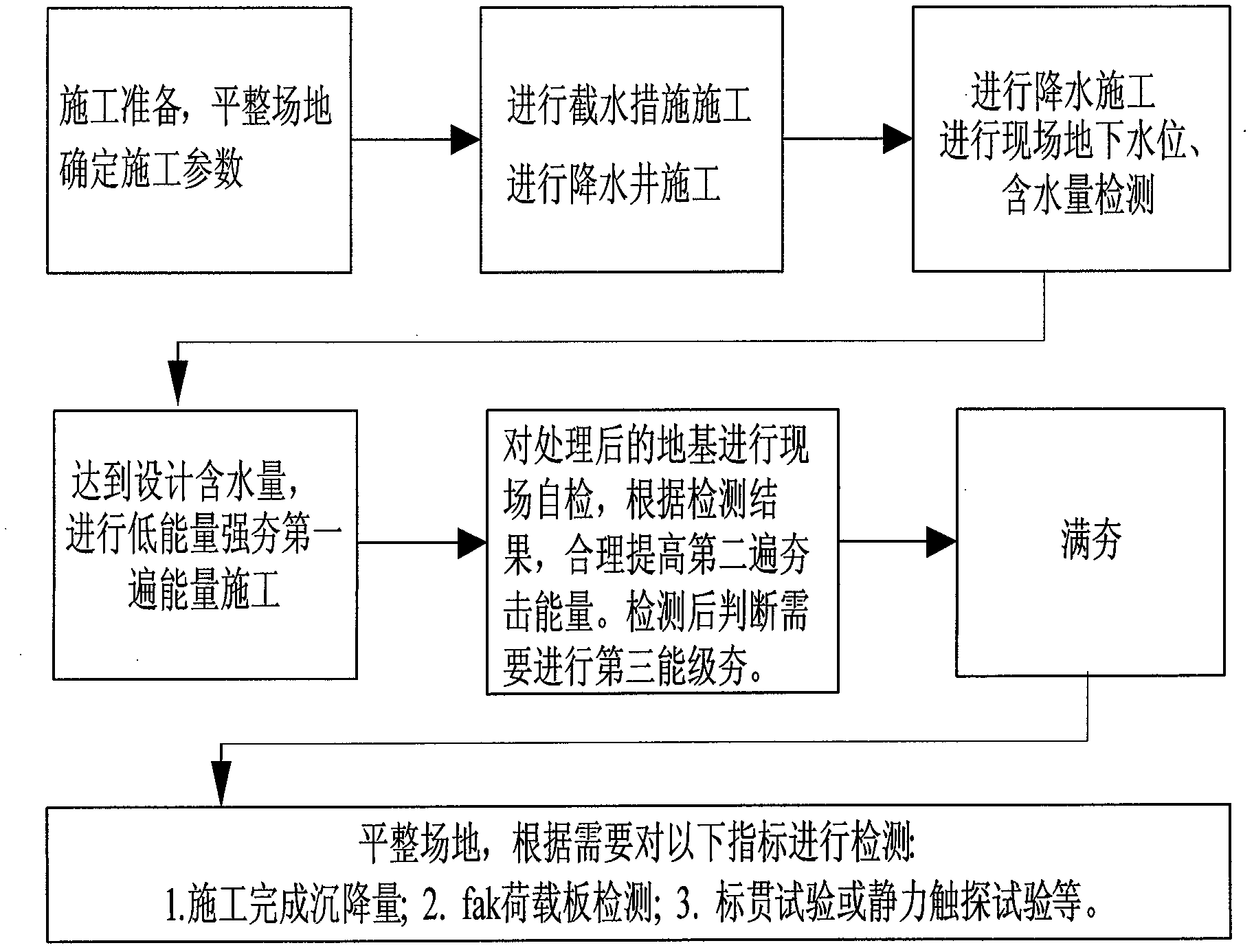

Method used

Image

Examples

example 1

[0029] The storage yard project in an exhibition area has a processing area of about 100,000 square meters. The soil layer: the first layer of plain fill: mainly clayey soil, with a thickness of about 0.6-4.6m, and the top is cultivated soil with a thickness of about 20cm. Composed of crushed stones, bricks and a small amount of cohesive soil; the second layer is brown-yellow to gray-yellow silty clay, with a thickness of about 0.5-2.7m, containing iron oxide spots and ferromanganese concretions, with powdery soil lumps, and the soil quality is composed of Gradually soften from top to bottom. The third layer is grayish-yellow to gray silt, with a thickness of about 1.30-4.80m, containing mica and organic matter, with a small amount of silty soil, and the permeability coefficient is 10-4cm / s; the fourth layer is muddy silty clay, with a thickness of About 8.20-14.30m, it is in flow-plastic state, has high compressibility, contains organic matter, sandwiches thin layer of silt...

example 2

[0047] A road project with a total length of 2.1km and a width of 60m, the main road in the development zone, with a processing area of about 120,000m 2 , Soil layer conditions: the first layer is miscellaneous fill: mainly weathered sand, gravel and cohesive soil, with an average thickness of 1.7m; the second layer is silty clay: soft plastic, with an average thickness of 1.5m; the third layer It is silty silty sand: flow plastic, permeability coefficient is 1.0*10-4cm / s, layer thickness is about 4m; the fourth layer is silty clay: permeability coefficient is 1.0*10-6cm / s, layer thickness is about 6m; the fifth layer is a coarse gravel layer: the thickness of the layer is about 10m, and the permeability coefficient is 1.0*10-2cm / s.

[0048] In this project, according to the road design requirements, the bearing capacity after foundation treatment is 120kPa, and the post-construction settlement is less than 30cm. It is required to form a hard shell with a thickness of about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com