Method for preparing patterning nanofiber membrane by utilizing insulating receiving template static spinning

A nanofiber membrane and patterning technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of inability to prepare nanofiber membranes, unable to precisely control fiber deposition, etc., to promote the development of applications, controllable and repeatable, pattern-accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

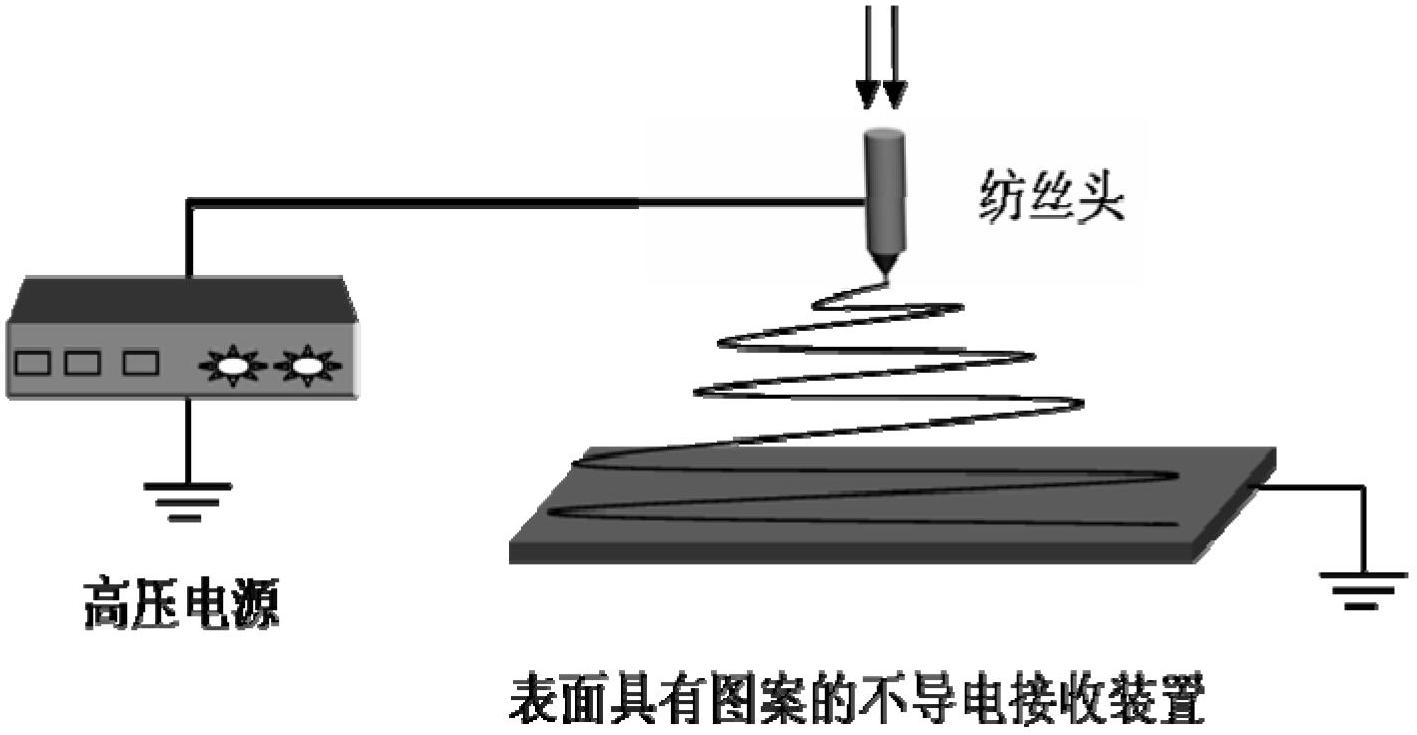

[0035]Dissolve 0.5g gelatin and 0.5g polycaprolactone in 10ml of trifluoroethanol, add 20ul acetic acid to the solution, stir for 24h until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) spinning solution. Use a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on a micro-injection pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 16kv, receiving distance 14cm, injection rate 1ml / h, ambient temperature 26°C, and ambient relative humidity 55%. A polystyrene foam with a thickness of 25 mm was used as a receiving device, and a nanofibrous membrane with a patterned structure was obtained. The conductivity of polystyrene is (σ)10 -16 S / m, is a typical insulating material. Therefore, it can be considered that the deposition of electrospun fibers is controlled by the surface topography of t...

Embodiment 2

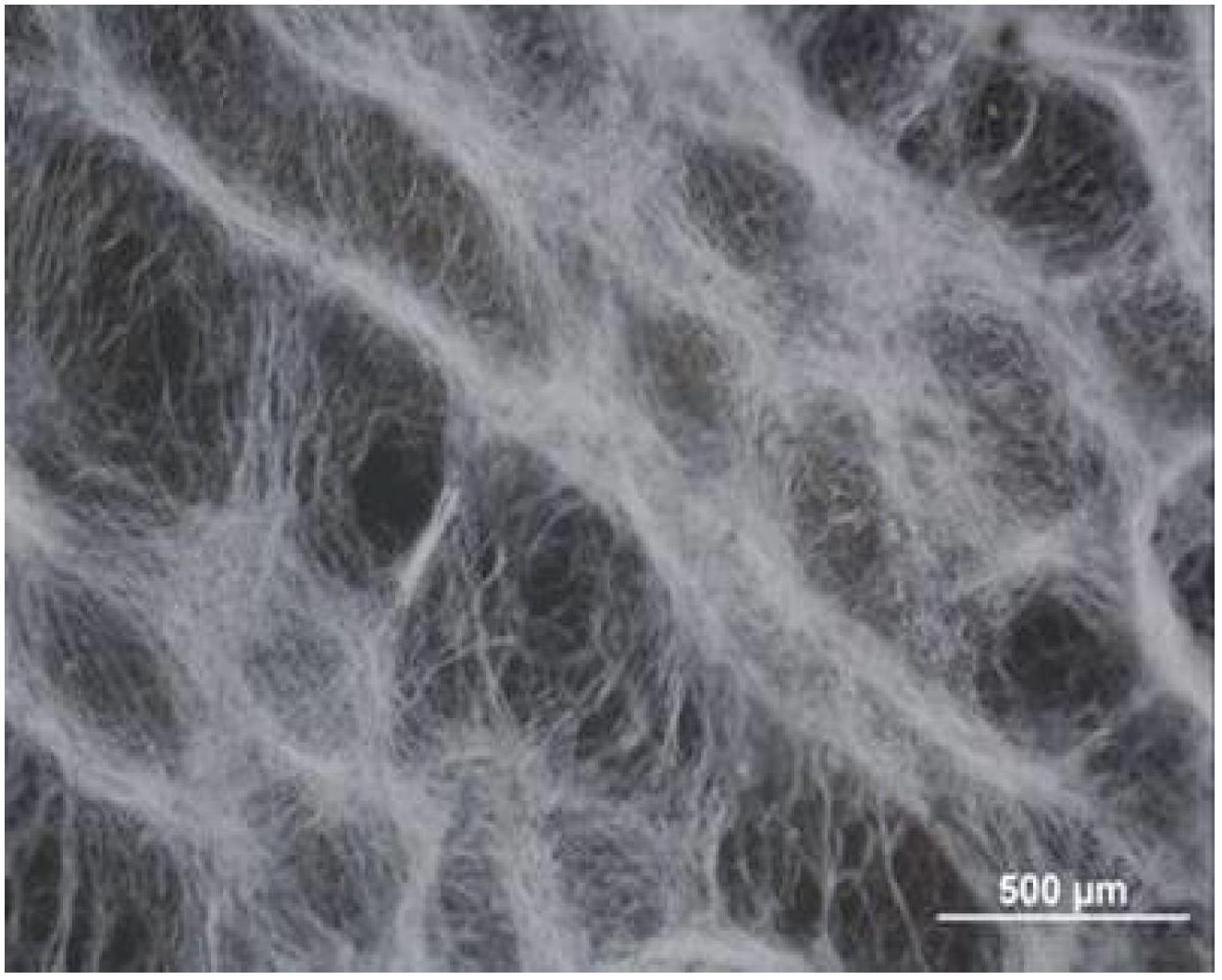

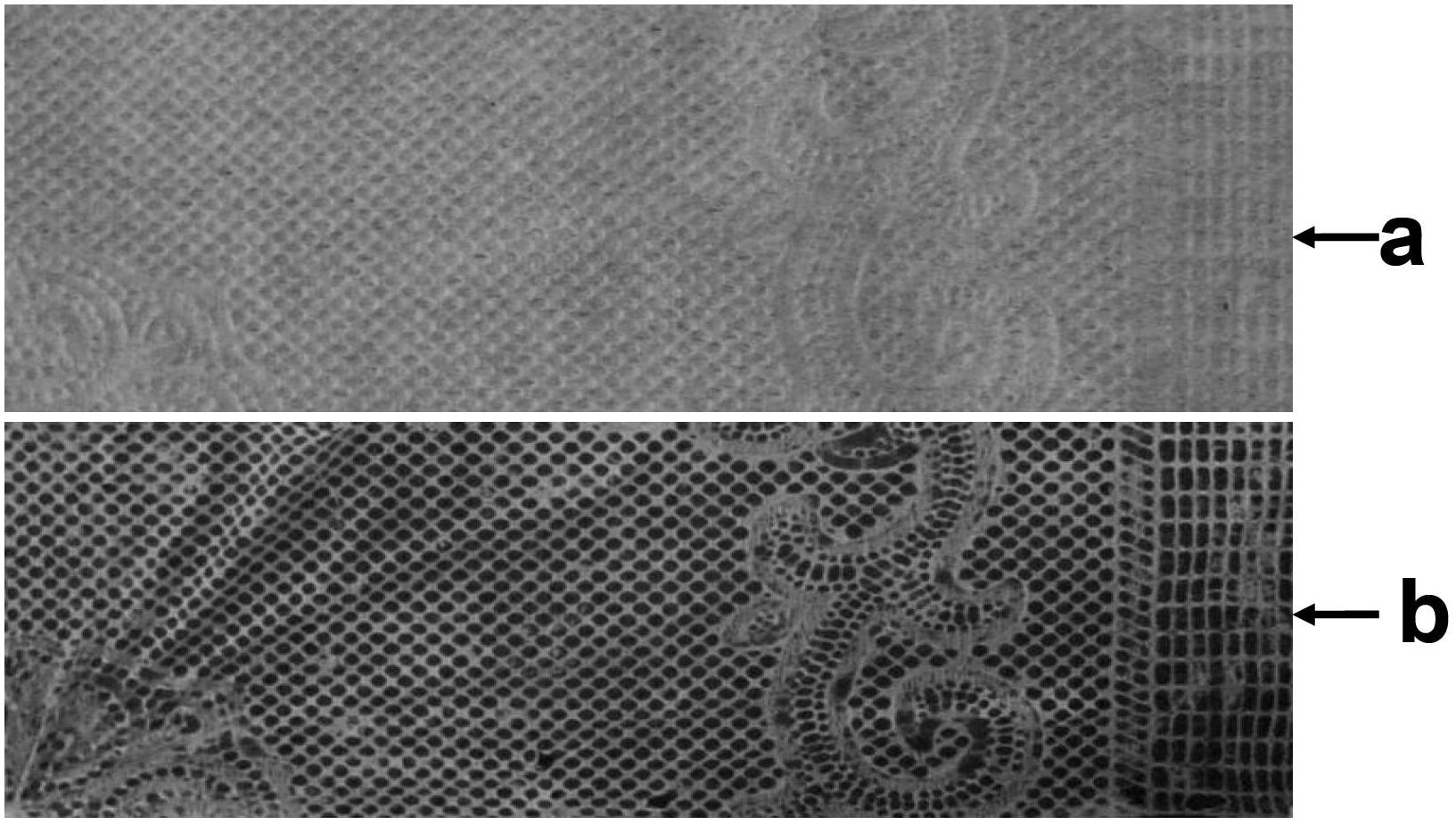

[0037] Dissolve 0.7g gelatin and 0.3g polycaprolactone in 10ml of trifluoroethanol, add 20ul acetic acid to the solution, stir for 24h until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) spinning solution. Use a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on a micro-injection pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 12kv, receiving distance 11cm, injection rate 2ml / h, ambient temperature 28°C, and ambient relative humidity 45%. Using a patterned napkin as a receiving device, a nanofibrous film with a patterned structure is obtained, which is very similar to its surface pattern. Such as image 3 , where a is the receiving device (a napkin with a pattern), and b is the fiber film obtained with the receiving device. Figure 4 A magnified view of patterned fibers electros...

Embodiment 3

[0039] Dissolve 0.6g gelatin and 0.4g polycaprolactone in 10ml of trifluoroethanol, add 20ul acetic acid to the solution, stir for 24h until completely dissolved, and obtain gelatin / polycaprolactone with a concentration of 10% (g / ml) spinning solution. Use a 10ml syringe and a needle with an inner diameter of 1.2mm to extract the gelatin / polycaprolactone spinning solution and fix it on a micro-injection pump. through as figure 1 The electrospinning device shown is used for electrospinning, and the parameters are: voltage 15kv, receiving distance 12cm, injection rate 2ml / h, ambient temperature 23°C, and ambient relative humidity 54%. Using toilet paper commonly used in daily life as the receiving device, a nanofibrous membrane with a patterned structure that is very similar to its surface embossed pattern was obtained. Figure 5 It is a magnified electron microscope image of toilet paper; Figure 6 A magnified view of the patterned fiber electrospun with toilet paper as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com