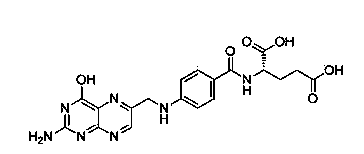

Medicinal folic acid purifying method

A purification method, technology of folic acid, applied in the direction of organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

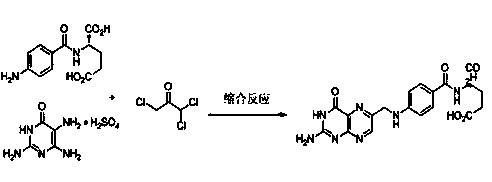

Method used

Image

Examples

Embodiment 1

[0028] Slowly add 470 ml of 40% sulfuric acid solution to 50 g of crude folic acid (tested by the Pharmacopoeia HPLC method, the purity of folic acid is 91.1%, and the content of pteroic acid is 2.8%), control the temperature at about 55°C, and stir until the solid is completely dissolved, and stir for half an hour. Slowly add 1.6L of purified water dropwise, temperature control ≤ 60°C, stirring speed 750 rpm, solid precipitates, cool down, filter with suction, wash with a small amount of ethanol, and dry. Add the refined product into purified water, heat to 90-100°C, add 5.8g of sodium hydroxide in batches, adjust pH=11.9 until the solid is completely dissolved, add 2.5g of activated carbon, heat to boiling for 45 minutes, and filter while hot. Slowly add 6M hydrochloric acid solution dropwise to the mother liquor while it is hot, adjust the pH=2.9, cool down and stir to crystallize, filter with suction, wash with sodium bicarbonate solution, purified water and a small amount ...

Embodiment 2

[0030] Add 50g of crude folic acid (tested by Pharmacopoeia HPLC method, folic acid purity 91.1%, pteroic acid content 2.8%) into 1.5L of purified water, heat to 90-100°C, add 8.3g of solid sodium hydroxide in batches, adjust pH=11.8 , when the solid is completely dissolved, add 2.5g of activated carbon, heat to boiling for 45 min, and filter while hot. Slowly add the mother liquor while hot concentrated hydrochloric acid solution , adjust the pH=2.2, cool down, stir and crystallize, and filter and dry. Slowly add 450ml of 40% sulfuric acid solution into the primary refined folic acid, control the temperature at about 55°C, stir until the solid is completely dissolved, and stir for half an hour. Slowly add 1.5 L of purified water dropwise, temperature control ≤ 60°C, stirring speed 750 rpm, solid precipitates, cool down, filter with suction, wash with a small amount of ethanol, and dry. Add the secondary refined product into purified water, heat to 90-100°C, add 6.0g of sod...

Embodiment 3

[0032]Add 50 g of crude folic acid (tested by Pharmacopoeia HPLC method, folic acid purity 91.1%, pteroic acid content 2.8%) into 1.5 L of purified water, heat to 90-100 °C, add 8.5 g of solid sodium hydroxide in batches, adjust pH=12.1, After the solid is completely dissolved, add 2.5 g of activated carbon, heat to boiling for 45 min, and filter while hot. Slowly add 6M hydrochloric acid solution dropwise to the mother liquor while it is hot, adjust the pH=3.1, cool down, stir and crystallize, and filter and dry. Will 50% sulfuric acid solution Slowly add 440ml into the primary refined folic acid, control the temperature at about 55°C, stir until the solid is completely dissolved, and stir for half an hour. Slowly add 1.5 L of purified water dropwise, temperature control ≤ 60°C, stirring speed 750 rpm, solid precipitates, cool down, filter with suction, wash with a small amount of ethanol, and dry. Add the secondary refined product into purified water, heat to 90-100°C, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com