Method of purifying ammonium tungstate solution

A solution purification, ammonium tungstate technology, applied in the direction of improving process efficiency, can solve the problem of ammonium tungstate solution purification methods need to be improved, and achieve the effect of simplifying operation, shortening process flow and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

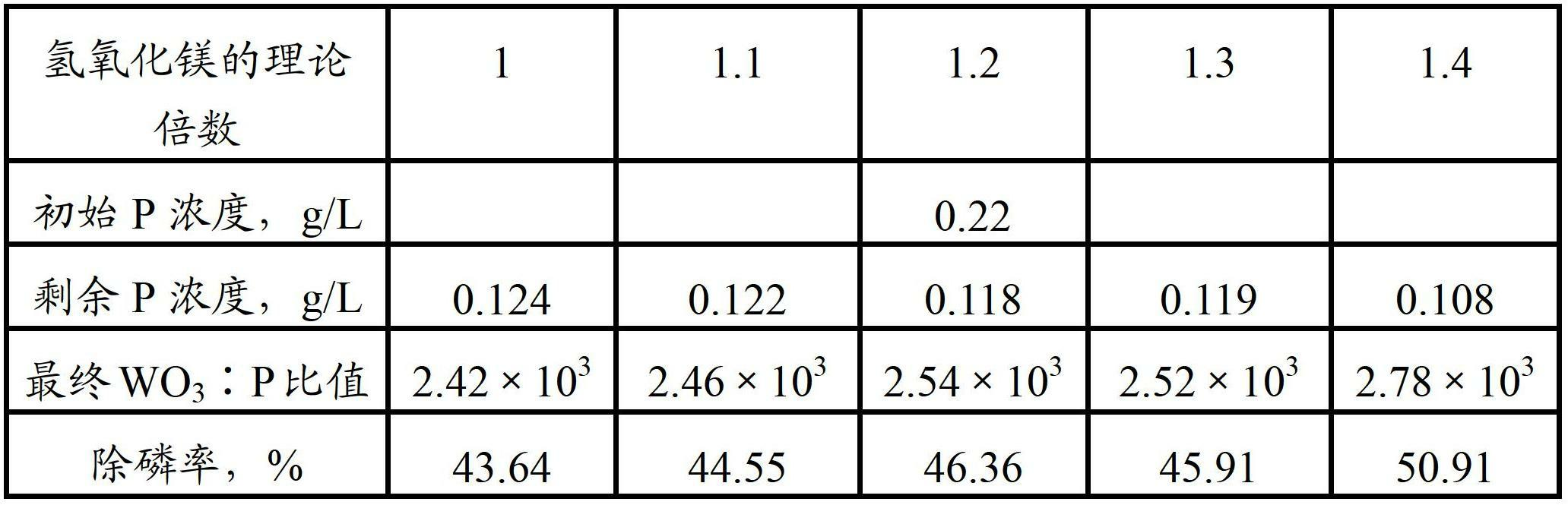

[0030] At room temperature, take 300ml containing WO 3Ammonium tungstate solution with a concentration of 230g / l and a phosphorus concentration of 0.22g / l is placed in a 500ml beaker, and an industrial ammonium sulfide solution of 1%-3.5% of the volume of the ammonium tungstate solution is added and stirred evenly, and then added to the above mixture respectively 1 to 1.4 times the theoretical amount of basic magnesium carbonate, magnesium sulfate heptahydrate, magnesium oxide, magnesium carbonate, magnesium hydroxide for deep phosphorus removal (for basic magnesium carbonate, magnesium sulfate heptahydrate, magnesium oxide, magnesium carbonate, hydroxide Magnesium, the amount of magnesium salt of 1 times the theoretical amount is respectively: 0.2069g, 0.5245g, 0.0858g, 0.1795g, 0.1235g), the pH value of the reaction solution=9-10, and the reaction time of phosphorus removal is 120min; After analysis, the experimental results are as follows:

[0031] 1. The effect of basic m...

Embodiment 2

[0052] Take 300ml of ammonium tungstate solution in a 500ml beaker, add 1 times the theoretical amount of industrial ammonium sulfide and 1 times the theoretical amount of magnesium carbonate respectively, the solution pH=9.0, react at room temperature for 2 hours, filter the ammonium tungstate solution obtained The concentration is 0.10g / L, and the removal rate of phosphorus is 54.55%.

Embodiment 3

[0054] Take 300ml of ammonium tungstate solution in a 500ml beaker, add 1 times the theoretical amount of industrial ammonium sulfide, 1.1 times the theoretical amount of light magnesium oxide, the solution pH=9.0, react at room temperature for 2 hours, filter the obtained ammonium tungstate The concentration of phosphorus in the solution was 0.016g / L, and the removal rate of phosphorus was 92.73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com