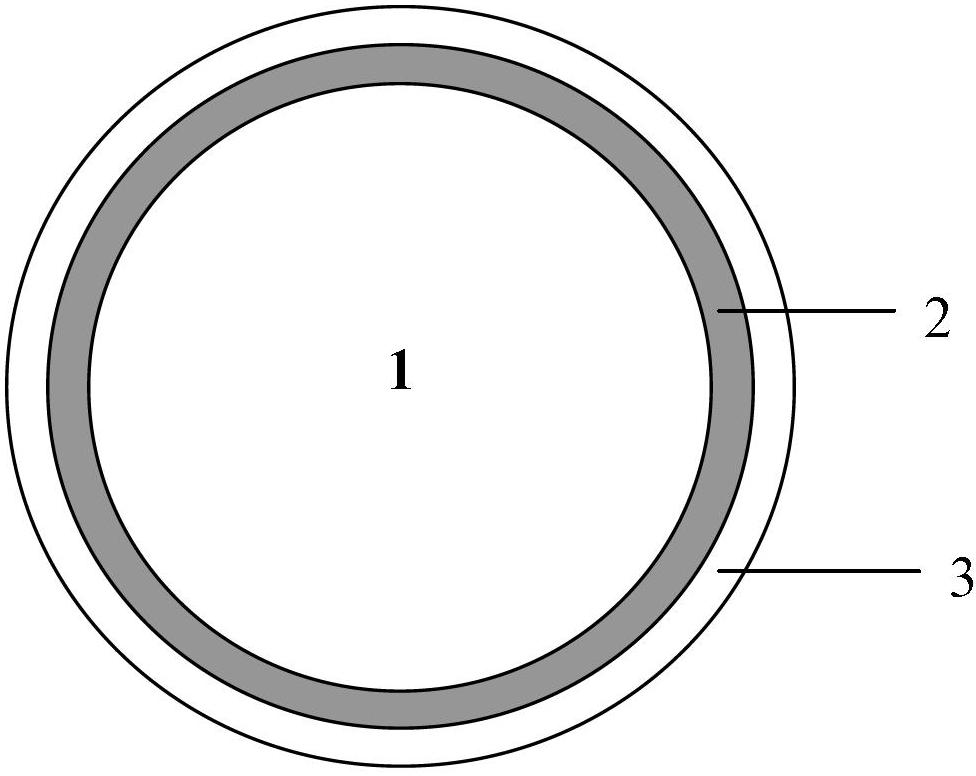

Sustained-release gel-breaking type fracturing propping agent and preparation method thereof

A fracturing proppant and proppant technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well parts, etc., to achieve the effect of reducing fragmentation, high strength and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

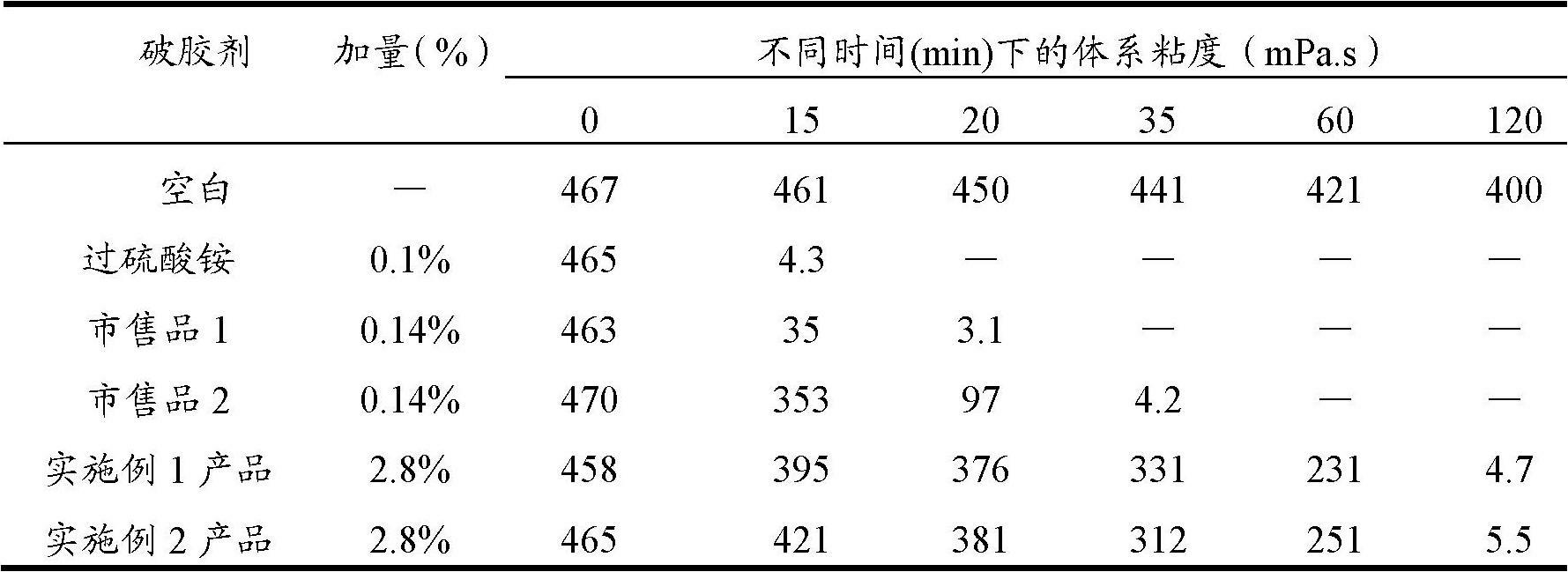

Examples

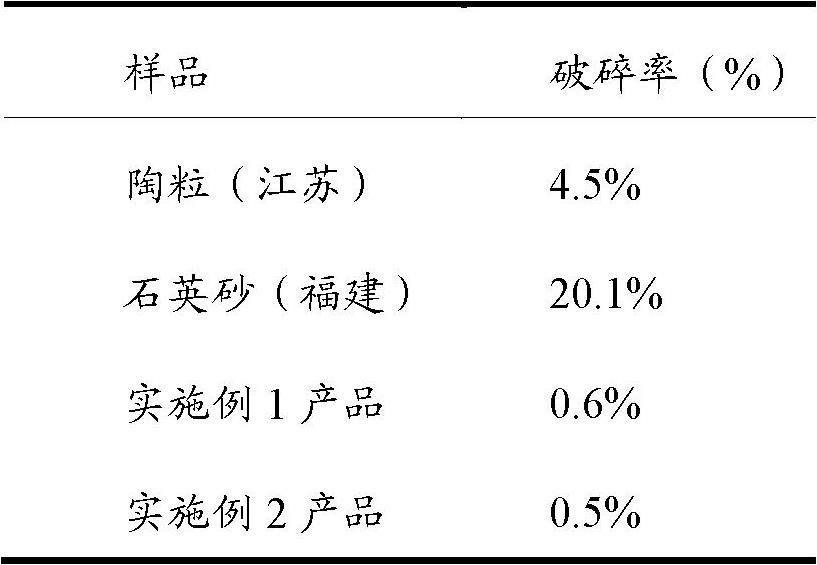

Embodiment 1

[0051] Preparation of A drug-loaded intermediate

[0052] (1) after weighing 50g of ammonium persulfate and 150g of silicon dioxide powder, pulverized and mixed, for subsequent use;

[0053] (2) take by weighing 25g of acrylic resin and dissolve in 500mL of ethanol, to prepare 5% acrylic resin ethanol solution for subsequent use;

[0054] (3) Weigh 1kg of 20-40 mesh ceramsite and place it on the turntable of the granulator;

[0055] (4) Turn on the granulator, adjust the rotating speed of the turntable to be 100rpm, and the blast frequency to be 10HZ;

[0056] (5) Sprinkle powder (mixed powder of ammonium persulfate and silicon dioxide) while spraying liquid (acrylic resin ethanol solution) (use a duster to spread the powder evenly);

[0057] (6) the coated sample is crossed with a 40 mesh sieve, and the uncoated fine powder is sieved;

[0058] (7) The final sample was dried in a 35°C oven for 0.8 h to obtain a drug-loaded intermediate.

[0059] The coating rate of the dru...

Embodiment 2

[0070] Preparation of drug-loaded intermediates

[0071] (1) after weighing 60g of ammonium persulfate and 240g of silicon dioxide powder, pulverized and mixed, for subsequent use;

[0072] (2) take by weighing 25g of acrylic resin and dissolve in 500mL of ethanol, to prepare 5% acrylic resin ethanol solution for subsequent use;

[0073] (3) Weigh 1kg of 20-40 mesh ceramsite and place it on the turntable of the granulator;

[0074] (4) Turn on the granulator, adjust the rotating speed of the turntable to be 100rpm, and the blast frequency to be 10HZ;

[0075] (5) Sprinkle powder (mixed powder of ammonium persulfate and silicon dioxide) while spraying liquid (acrylic resin ethanol solution) (use a duster to spread the powder evenly);

[0076] (6) the coated sample is crossed with a 40 mesh sieve, and the uncoated fine powder is sieved;

[0077] (7) The final sample was dried in a 35°C oven for 0.8 h to obtain a drug-loaded intermediate.

[0078] The coating rate of the drug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com