NiCuZn soft magnetic ferrite material used for low temperature co-sintering and preparation method thereof

A technology of soft ferrite and low-temperature co-firing, which is applied in the field of soft ferrite materials, can solve problems such as material performance differences, and achieve the effects of good consistency, excellent magnetic properties, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

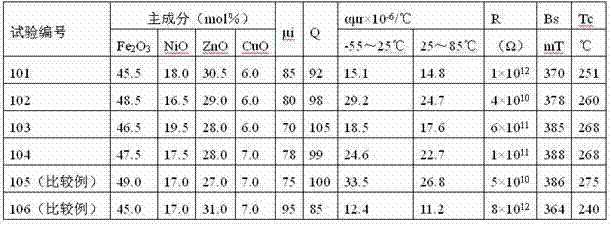

Embodiment 1

[0037] Weigh Fe with the main component content shown in Table 1 2 o 3 , NiO, ZnO and CuO raw materials are dry-mixed and vibrated, and then pre-fired in an air kiln at 800°C for 120 minutes to obtain pre-fired powder after preliminary reaction. Based on the weight of the calcined powder, add an appropriate amount of secondary components to the calcined powder (relative to the total weight of the main component, the weight percentage of the secondary components in terms of their respective standards is: 0.2wt% MnO, 2.5wt% Bi 2 o 3 , 0.5wt% Co 2 o 3 , 0.05wt% V 2 o 5 , 0.1wt% ZrO 2 , 0.2wt% SiO 2 , manganese oxides with Mn 3 o 4 The form of adding), sand milling for 60 minutes, the average particle size of the obtained particles is 7.5 μm, then add 0.8wt% binder polyvinyl alcohol and dry and granulate, the average particle size of the obtained particle powder is 10 μm , water content <0.3wt%, the powder is pressed into a standard ring blank φ25×φ15×5 by tape casting ...

Embodiment 2

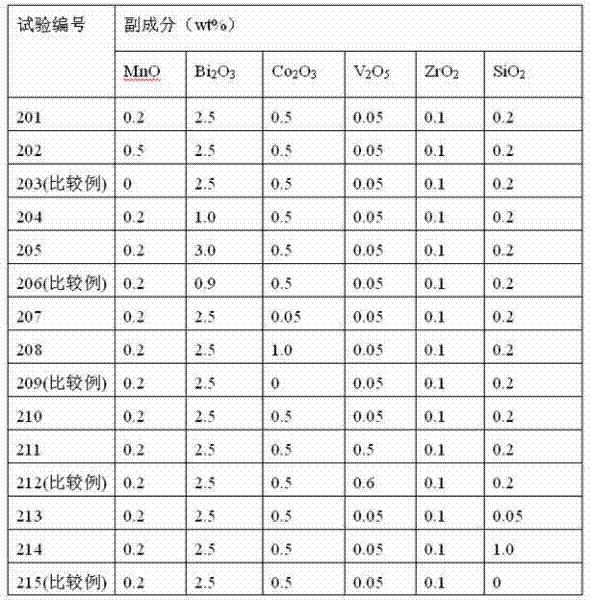

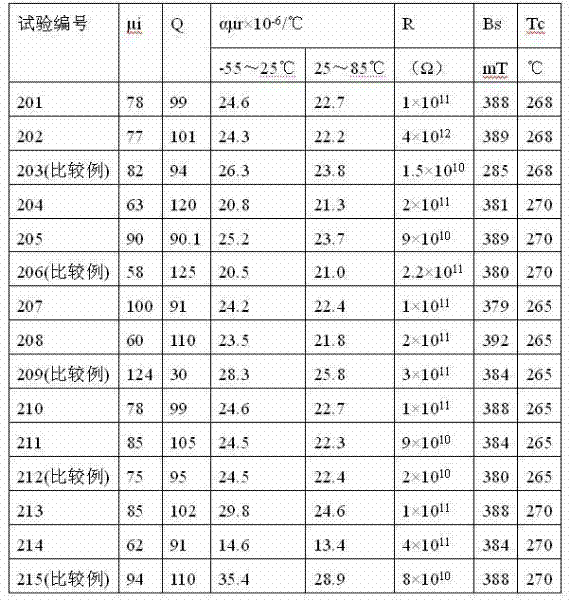

[0043] The preparation process of the magnetic core is the same as that of Example 1. Only Fe in the main ingredient formula 2 o 3 , NiO, ZnO, CuO content fixed at 47.5mol% Fe 2 o 3 , 17.5 mol% NiO, 28.0 mol% ZnO and 7.0 mol% CuO. The contents of subcomponents are shown in Table 2.

[0044] Table 2

[0045]

[0046] Continued Table 2

[0047]

[0048] It can be seen from Table 2 that when the content of the auxiliary components is within the scope of the present invention, the performance of the magnetic permeability μi, the saturation magnetic flux density of the magnetic core, the Q value, the specific temperature coefficient αμr, and the Curie temperature Tc is better. When the main formula deviates from the present invention, there is a tendency that the saturation magnetic flux density decreases, the specific temperature coefficient αμr increases, and one or some of the performances of the surface resistance and Q value decrease at the same time.

Embodiment 3

[0050] The composition of the magnetic core is the same as that of test number 104#, and the preparation process is the same as that of Example 1. Only the pre-burning temperature is shown in Table 3.

[0051] table 3

[0052]

[0053] It can be seen from Table 3 that when the burn-in temperature is within the range of the present invention, the magnetic permeability μi, the saturation magnetic flux density of the magnetic core, the Q value, the specific temperature coefficient αμr, and the Curie temperature Tc are better. When it is lower than or higher than 750-850°C, there is a tendency that the saturation magnetic flux density decreases, the specific temperature coefficient αμr increases, and one or some of the surface resistance and Q value tends to decrease at the same time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com