Sound absorption and insulation composite material structure

A composite material, sound-absorbing and insulating technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve unexisting problems and achieve good sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

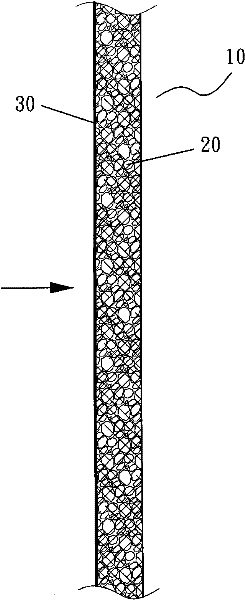

[0031] see figure 1 As shown, the first embodiment of the present invention is a sound-absorbing composite material 10 as a whole, and its structure is basically composed of at least one non-woven fiber layer 20 and at least one polyethylene film 30 (Polyethylene, PE). figure 1 It is a schematic diagram showing the structure of the sound-absorbing and insulating composite material 10, which is composed of a non-woven fiber layer 20 and a polyethylene film 30, which is called "single-layer single-pasting type". Wherein, the non-woven fabric fiber layer 20 is a fiber laminated layer made by a non-woven fabric manufacturing method, which can be made of recycled and environmentally friendly fiber materials to achieve the effect of environmental protection, energy saving and carbon reduction, but it does not rule out that it can be made of any fiber material; 1mm (inclusive), the main function is to support one (at least one) fiber stacked layer formed by interlacing and interlacin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com