Extruded glass reinforced plastic electric part supporting system

A technology for supporting systems and electrical devices, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Corrosion and other problems, to achieve the effect of convenient maintenance and update, strong mechanical performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

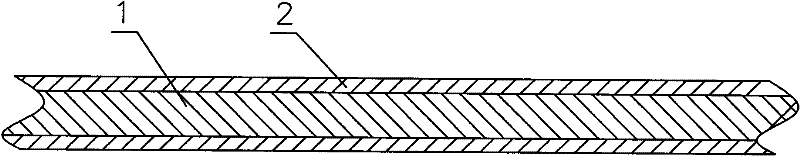

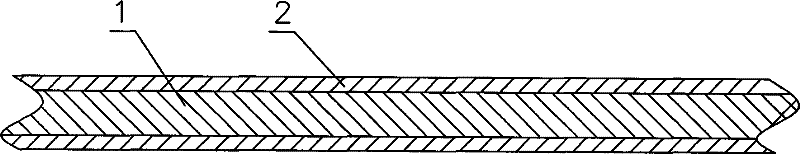

[0010] The invention includes a base layer 1, the base layer 1 is based on vinyl resin, and is reinforced by ECR alkali-free modified yarn, and the base layer 1 is provided with an outer layer 2 of alkali-free stitch-bonded felt.

[0011] The production material of the present invention preferentially uses 4300H1 vinyl resin as the base material. The 4300H1 vinyl resin is a new type of resin developed in China. The properties and testing results of the resin are superior to those of epoxy resin. It is more operable than epoxy resin in many aspects; at the same time, it adopts ECR alkali-free modified yarn that meets environmental protection requirements and alkali-free stitched felt produced by ECR alkali-free modified yarn. ECR alkali-free modified yarn is currently in line with EU environmental protection requirements. New product, this product is not only alkali-free, but also boron-free and fluorine-free. It has good permeability and plasticity, and can be used as a reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com