Dispersed flotation separation method for carbonate-containing iron ore

A separation method and technology for iron ore, applied in flotation, solid separation and other directions, can solve the problems of complex symbiotic relationship, loss of iron metal, and indistinguishable fine tails, etc., and achieve the effect of simple process flow, low cost and elimination of influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

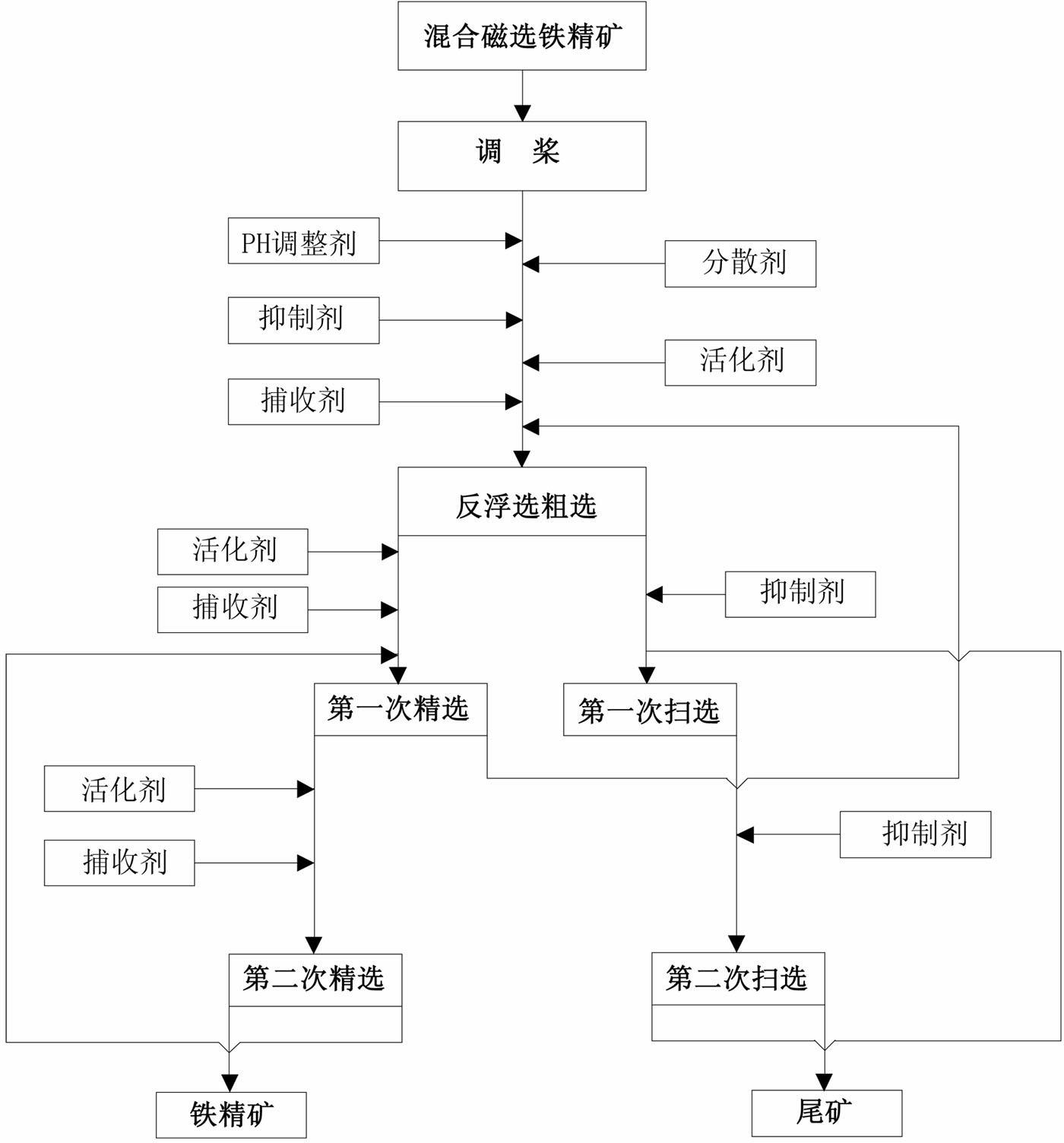

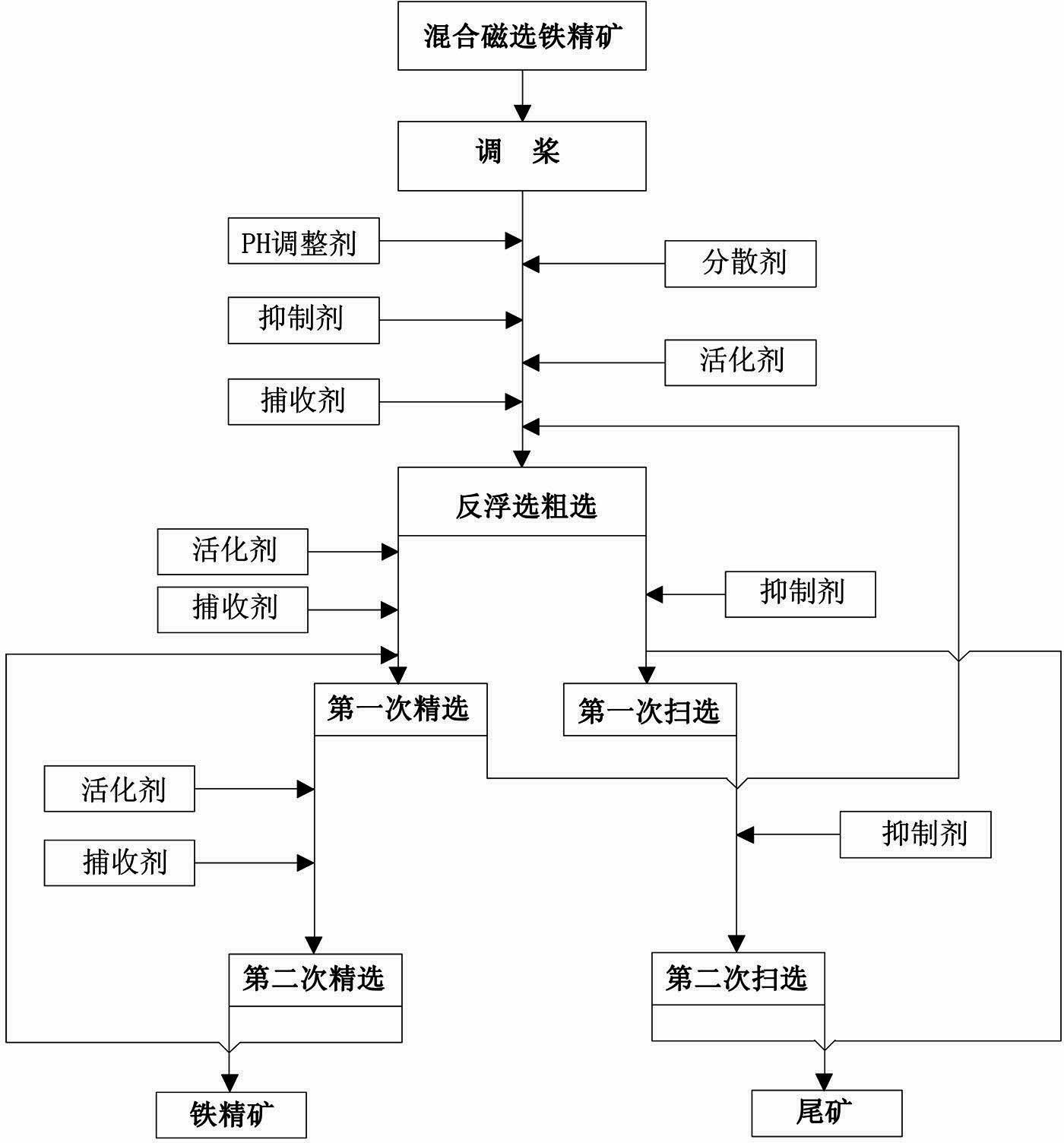

Method used

Image

Examples

Embodiment 1

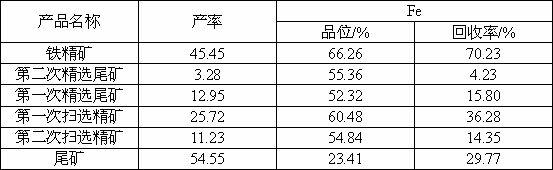

[0060] Example 1: The following reverse flotation method steps are employed:

[0061] The mass concentration of the slurry of mixed magnetic separation iron concentrate is controlled at 25%, and it is fed into the roughing operation, and the temperature of the slurry is controlled at 38-42°C. At a stirring speed of 2800rpm, sodium hydroxide is added to adjust the pH of the slurry to 11, and the slurry is stirred. 3min, add salted water glass, and stir for 3min, the amount of salted water glass is 800g / t, add starch, and stir for 3min, the amount of starch is 2200g / t, add lime, and stir for 3min, the amount of lime is 600g / t, finally add KS-Ⅲ, and stir for 3 minutes, the dosage of KS-Ⅲ is 1000g / t, roughing for 4.5 minutes;

[0062] The mass concentration of the tailings obtained by roughing is controlled at 20%, and it is put into the sweeping operation for two sweeps, one sweep, first adding sodium hydroxide, adjusting the pH of the slurry to 11, then adding starch, stirrin...

Embodiment 2

[0068] Adjust the pulp concentration and the amount of additives:

[0069] The mass concentration of iron ore concentrate in mixed magnetic separation is controlled at 35% for flotation operations. The dosage of adding salted water glass is 600g / t, the dosage of adding starch is 1800g / t, the dosage of adding lime is 500g / t, adding KS -Ⅲ dosage is 800g / t;

[0070] The mass concentration of the roughing tailings obtained by roughing is controlled at 20%, and two sweeps are carried out. The amount of starch added in the first sweep is 100g / t, and the amount of added starch in the second sweep is 50g / t;

[0071] The roughed concentrate obtained by roughing is subjected to 2 times of beneficiation, the first beneficiation, the dosage of adding lime is 200g / t, the dosage of adding KS-Ⅲ is 400g / t, and the second beneficiation, the dosage of adding lime is 200g / t t, the dosage of adding KS-Ⅲ is 200g / t.

[0072] All the other reverse flotation methods and steps are the same as in...

Embodiment 3

[0074] Adjust the pulp concentration and the amount of additives:

[0075] The mass concentration of the mixed magnetic separation iron concentrate is controlled at 30%, and it is fed into the flotation operation. The dosage of adding salinized water glass is 800g / t, the dosage of adding starch is 2000g / t, and the dosage of adding lime is 800g / t. The dosage of KS-Ⅲ is 1200g / t;

[0076] The mass concentration of the roughing tailings obtained by roughing is controlled at 20%, which is put into the scavenging operation for 2 times of scavenging. For the first scavenging, the amount of added starch is 100g / t, and for the second scavenging, the amount of added starch is 50g / t;

[0077] The roughed concentrate obtained by roughing is subjected to 2 times of beneficiation, the amount of added lime is 500g / t for the first beneficiation, the amount of added KS-Ⅲ is 500g / t, and the amount of added lime is 300g for the second beneficiation / t, the dosage of adding KS-Ⅲ is 300g / t.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com