Alfalfa dehydration silage harvesting technology and harvester

A harvester and alfalfa technology, applied in the field of alfalfa dehydration silage harvesting technology and harvester, can solve the problems of material loss, white pollution of stretch film, quality decline of alfalfa, etc., to reduce mechanical input costs, shorten harvest time, reduce Effects of Nutrient Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention provides a technique for harvesting alfalfa dehydrated silage and a harvester. The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

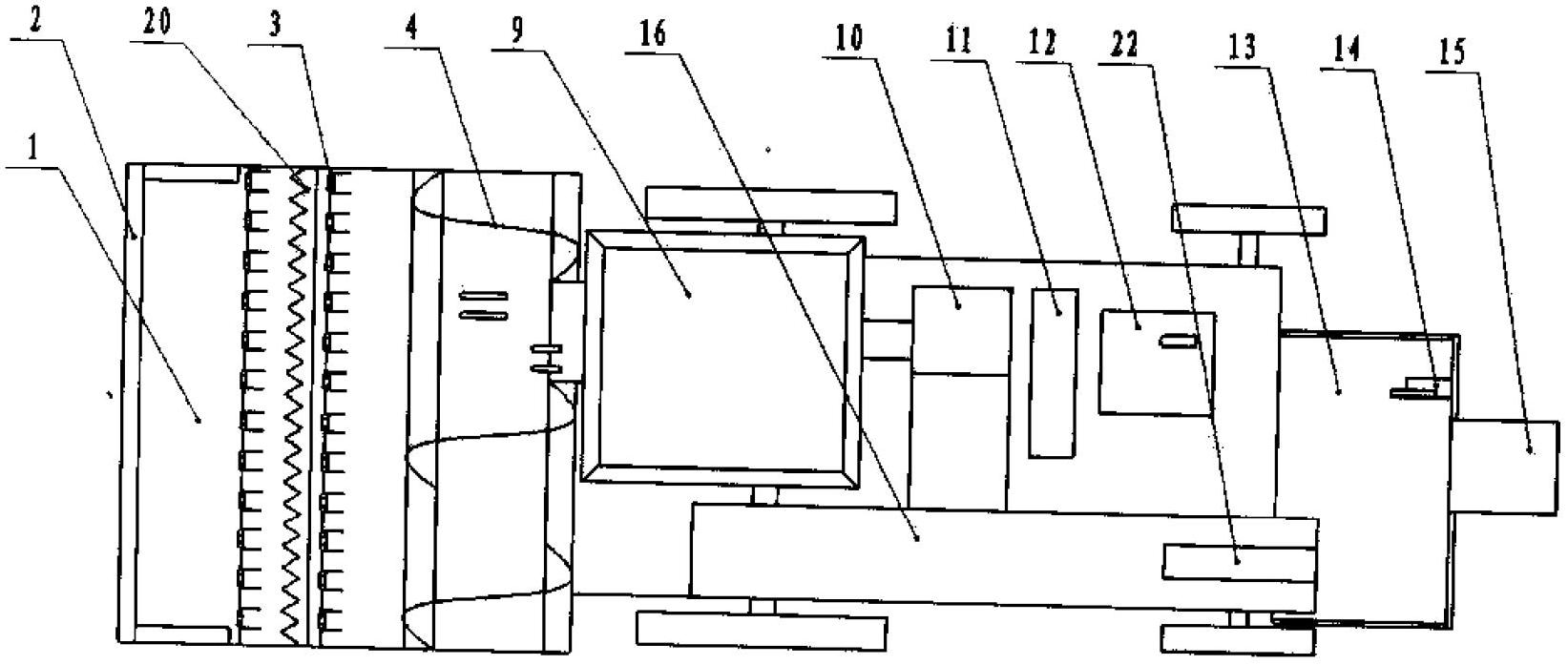

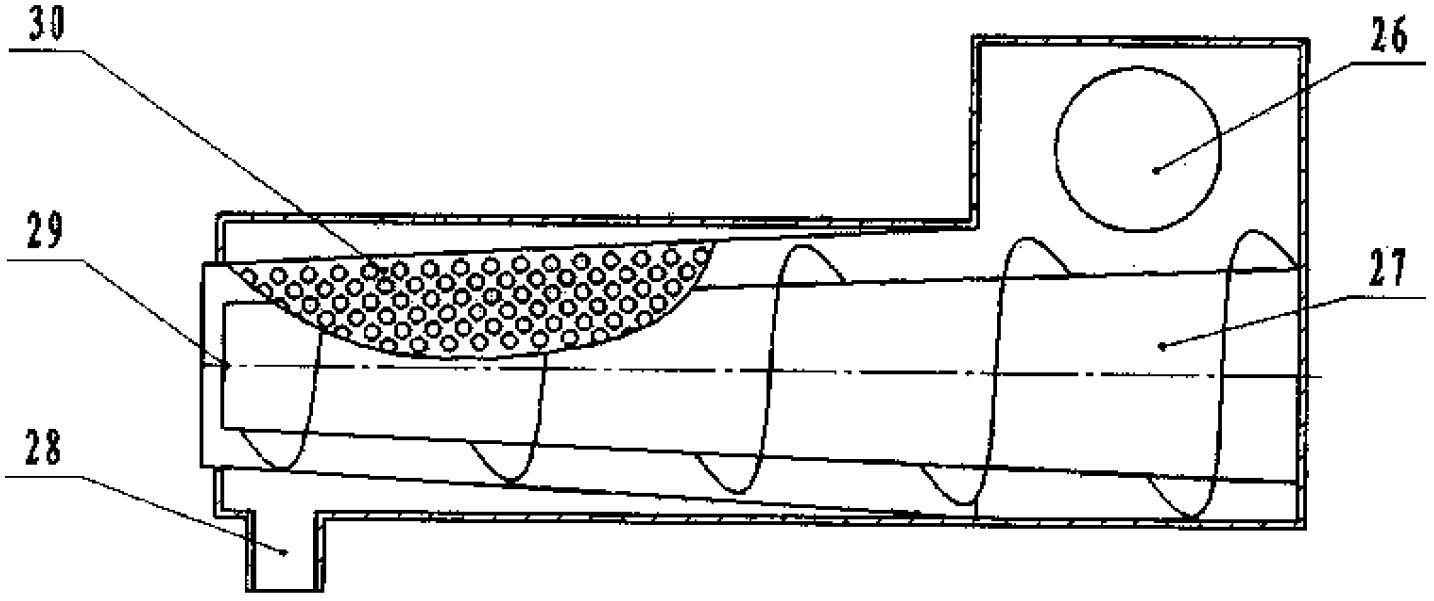

[0020] The overall structure and positional relationship of the alfalfa dehydration silage harvester is as follows: figure 1 , figure 2 As shown, pusher bar 2 is installed in the front of header 1, and is used to push alfalfa forward and tilts; At the bottom of platform 1 and below the reel 3, a screw conveyor 4 is installed behind the reel 3 to convey the material to the feeding device 7, and the front end of the feeding device 7 is equipped with a front upper feed roller 5 and a front lower feed roller 19 clamps the fresh grass of alfalfa, sends to the rear upper feeding roller 6 and the lower feeding roller 18 of the back, clamps the fresh grass of alfalfa and sends to the fixed knife 17 adjacent to the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com