Method for producing resin dispersion for antifouling coating

An antifouling paint and a manufacturing method technology, applied in antifouling/underwater paints, coatings, paints containing biocides, etc. Excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

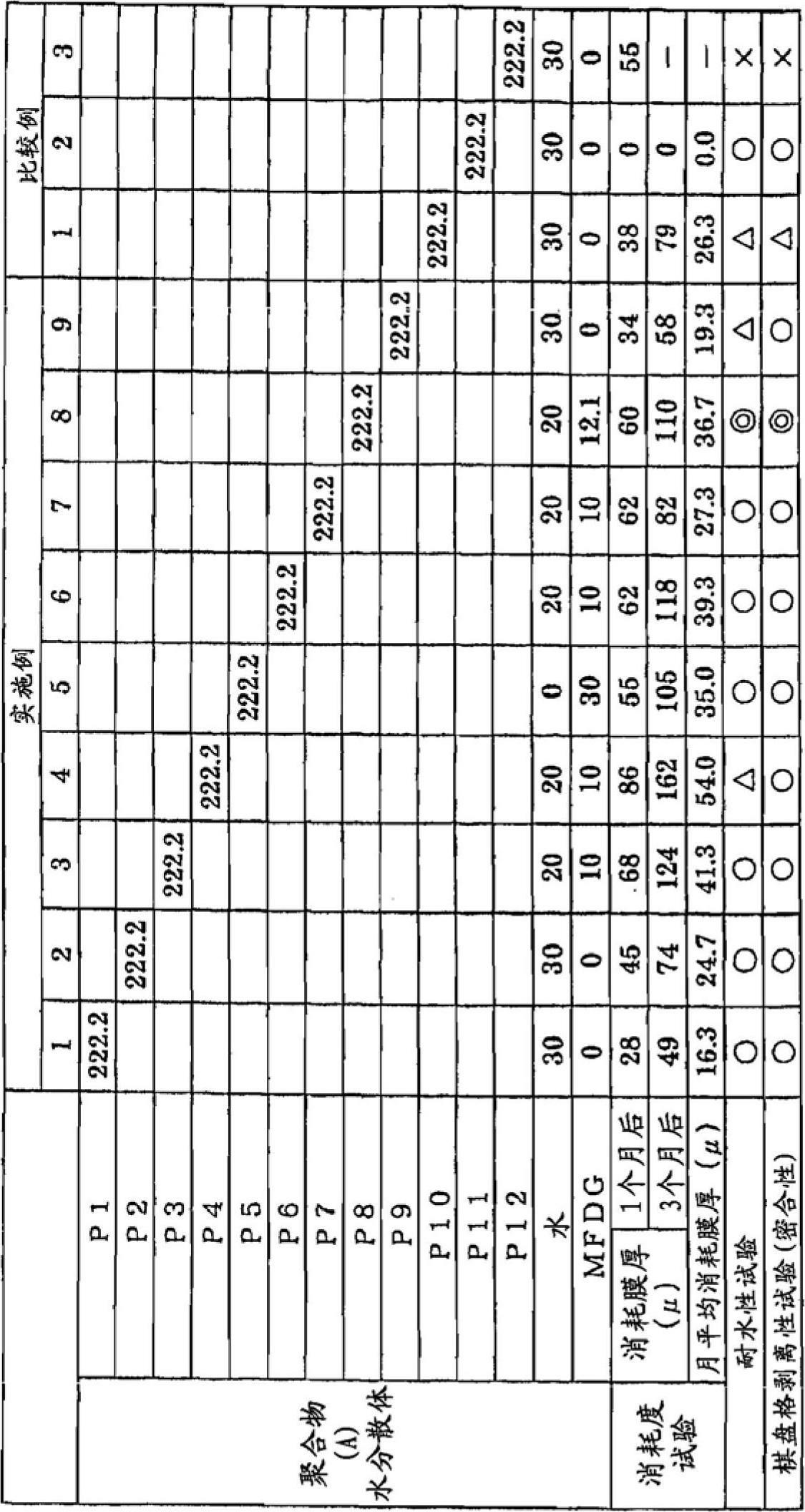

[0087] Hereinafter, although an Example and a comparative example demonstrate this invention in more detail, this invention is not limited at all by these examples. In addition, the part in an Example shows a mass part. The evaluation of the resin dispersion for antifouling paints prepared in this example was performed by the method shown below.

[0088] [Evaluation of storage stability]

[0089] In the evaluation of the storage stability of the resin dispersion for antifouling paint, the resin dispersion for antifouling paint was stored at a temperature of 40°C for 3 days, 10 days, and 1 month, and the presence or absence of sediment was checked visually . Evaluation was performed using the following criteria.

[0090] ○: Resin components do not precipitate, do not separate, and do not form coagulums after the specified time has elapsed

[0091] △: There is a small amount of sediment, but it is dispersed by stirring

[0092] ×: The resin component precipitates, separates...

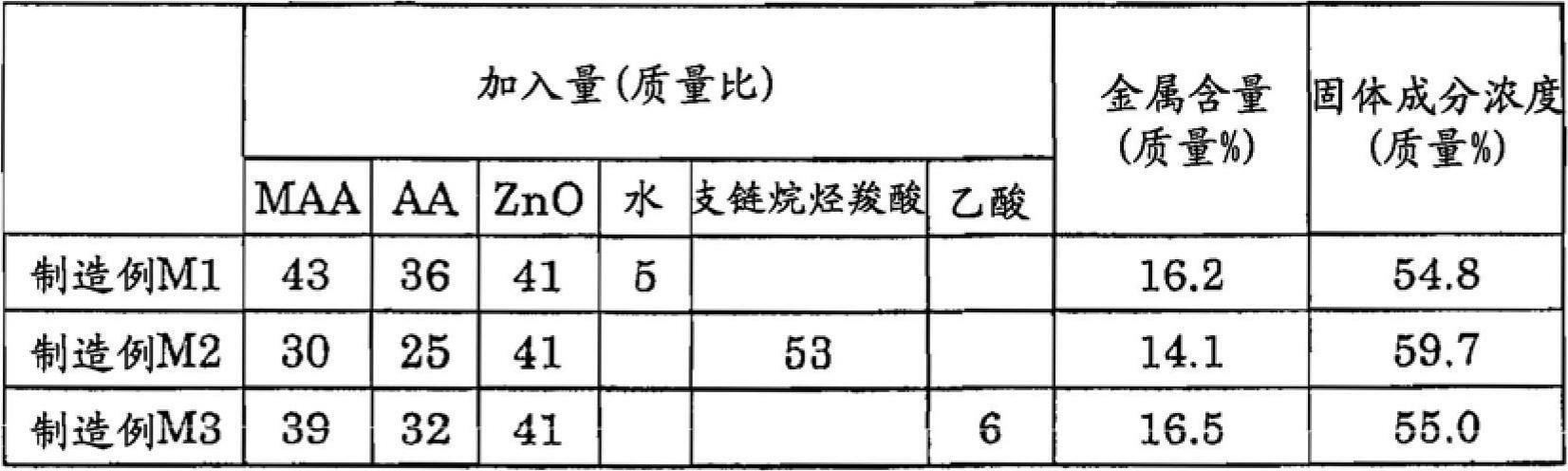

manufacture example M1

[0108] 66.3 parts of MFDG (dipropylene glycol monomethyl ether) and 41 parts of zinc oxide (ZnO) were added to the reaction container equipped with a stirrer, a temperature regulator, and a dripping device, and it heated up to 75 degreeC, stirring. A mixture consisting of 43 parts of methacrylic acid (MAA), 36 parts of acrylic acid (AA) and 5 parts of water was added dropwise thereto at a constant speed over 3 hours. After the dropwise addition, the reaction solution changed from milky white to transparent. Furthermore, after stirring for 2 hours, 10 parts of MFDG were added, and the transparent divalent metal containing ethylenically unsaturated monomer mixture M1 was obtained. Table 1 shows the addition amount of each raw material, the metal content and solid content concentration of the obtained divalent metal-containing ethylenically unsaturated monomer mixture M1.

manufacture example M2、M3

[0110] Divalent metal-containing ethylenically unsaturated monomer mixtures M2 and M3 were produced in the amounts shown in Table 1 in the same manner as in Production Example M1. However, instead of MFDG, PKA5001 was used in Production Example M2, and AG was used in Production Example M3.

[0111] [Table 1]

[0112]

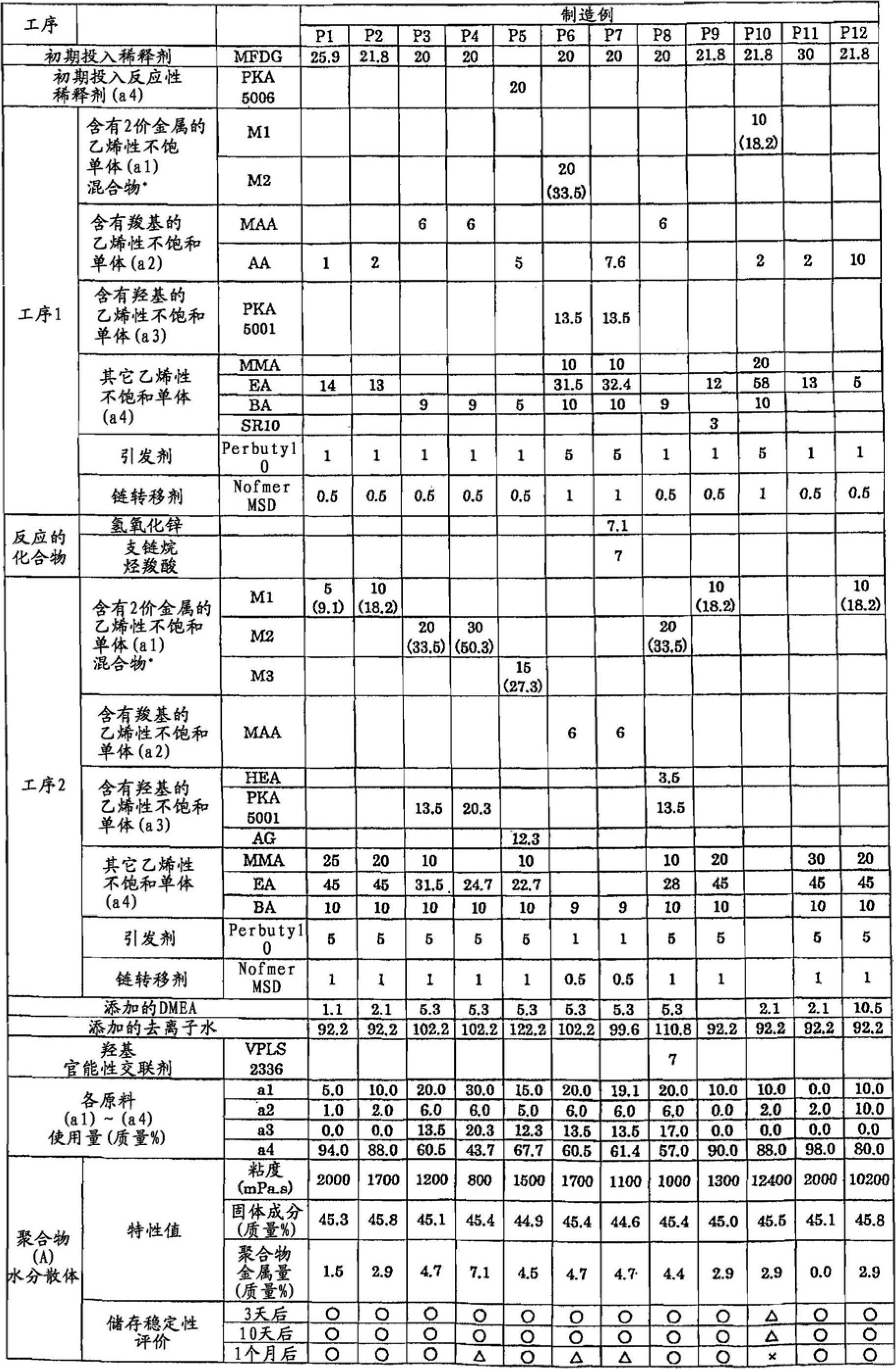

[0113] [Manufacturing example P1]

[0114] 25.9 parts of MFDG (dipropylene glycol monomethyl ether) were put into the reaction container equipped with the stirrer, temperature regulator, and dripping apparatus, and it heated up to 130 degreeC, stirring.

[0115]

[0116] Thereafter, a mixture composed of the following raw materials was added dropwise at a constant rate over 1 hour, and then a copolymerization reaction was performed for 0.5 hour (hereinafter, this reaction step is referred to as step 1).

[0117] Acrylic acid (AA) 1 part

[0118] 14 parts of ethyl acrylate (EA)

[0119] 0.5 parts of chain transfer agent (trade name: "Nofmer MSD", manufactu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com