Double-head light-emitting diode (LED) lamp strip chip mounter

A technology of LED light strips and placement machines, which is applied in the direction of assembling printed circuits with electrical components, can solve the problems of high equipment cost and slow speed, and achieve the effect of high degree of automation, cost reduction and placement speed improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

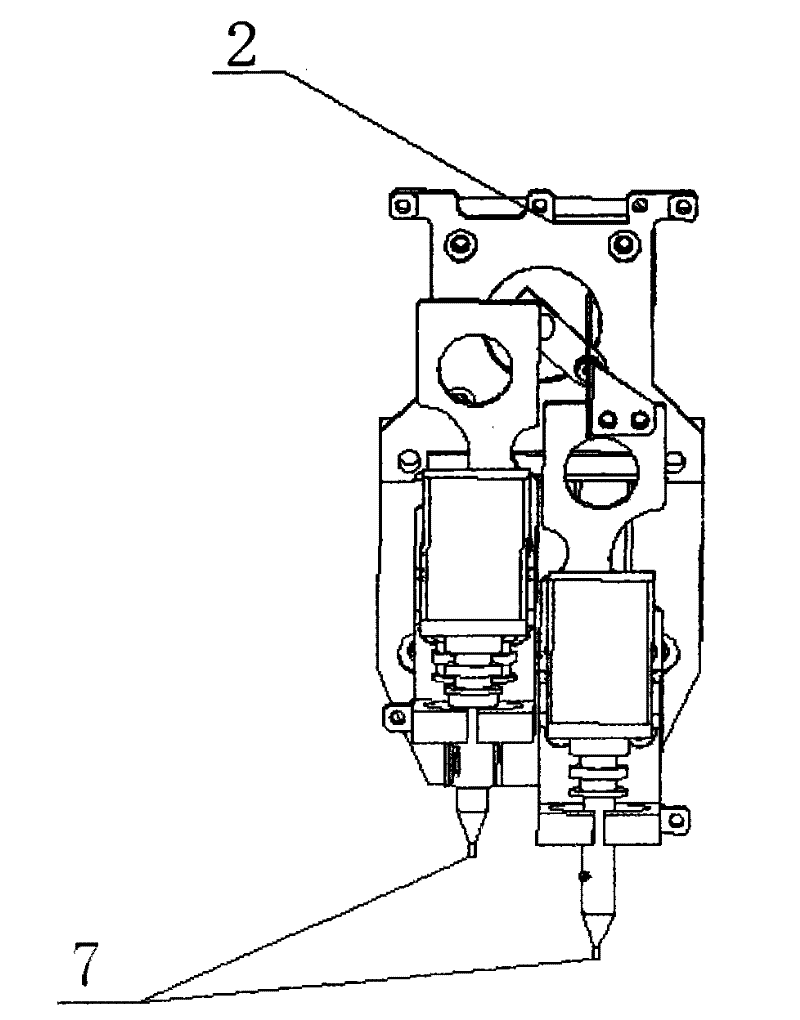

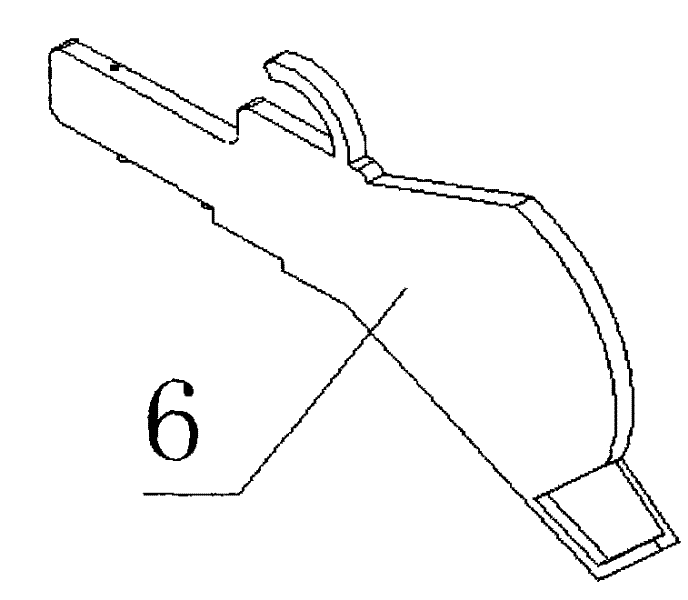

[0016] A double-headed LED light strip placement machine, including a base platform 5, an X-axis servo motor 3, a Y-axis servo motor 4, a PCB slide table 1, a placement head 2 and an automatic feeder 6, and the X-axis servo motor 3 is responsible for placing The feed in the X-axis direction of the mounting head 2, the Y-axis servo motor 4 is responsible for the feed in the Y-axis direction of the placement head 2, the PCB slide table 1 places the LED light strip board, and the PCB slide table 1 is slidably connected with the base platform 5. The head 2 is provided with double suction nozzles 7 .

[0017] Both the automatic feeder and the X2 sliding table work with the four-dimensional robot. The four-dimensional robot completes a series of actions: front, back, left, right, up, down, forward rotation, and reverse rotation. The automatic feeder 6 provides automatic feeding, each time the robot moves to the top of the automatic feeder 6 and picks up a piece of material, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com