Method for implementing self-calibration of current-limiting current value of motor controller

A motor controller and self-calibration technology, used in electrical testing/monitoring, etc., can solve the problems of difficulty in calibration and correction of current limiting current value, reduced production efficiency, complicated operation, etc., so as to simplify the current limiting current debugging steps and improve production efficiency. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0019] The first embodiment of the present invention provides a method for realizing the self-calibration of the current limiting current value of the motor controller, and the method is carried out according to the following steps:

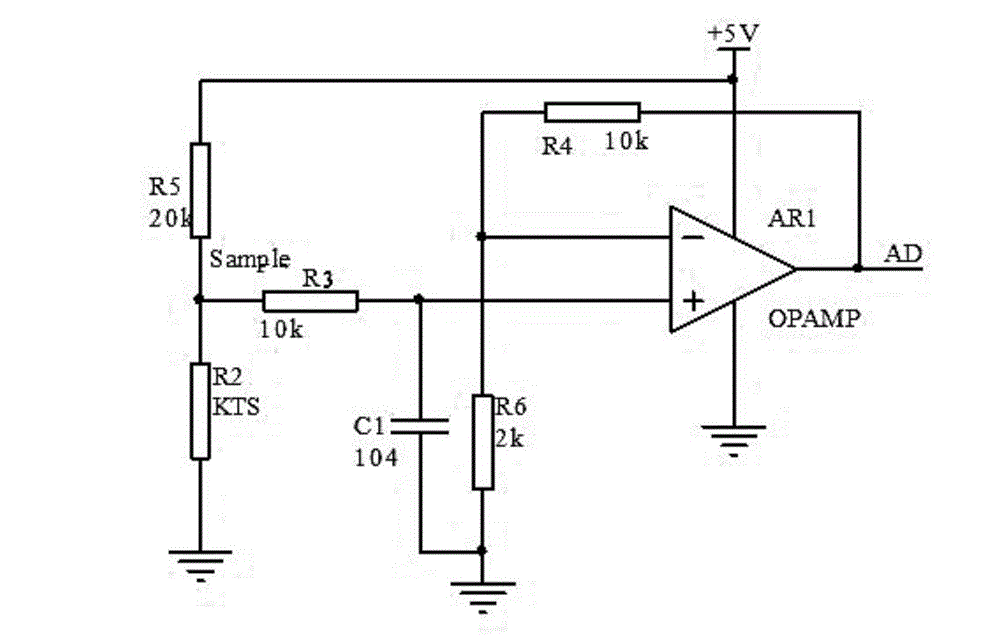

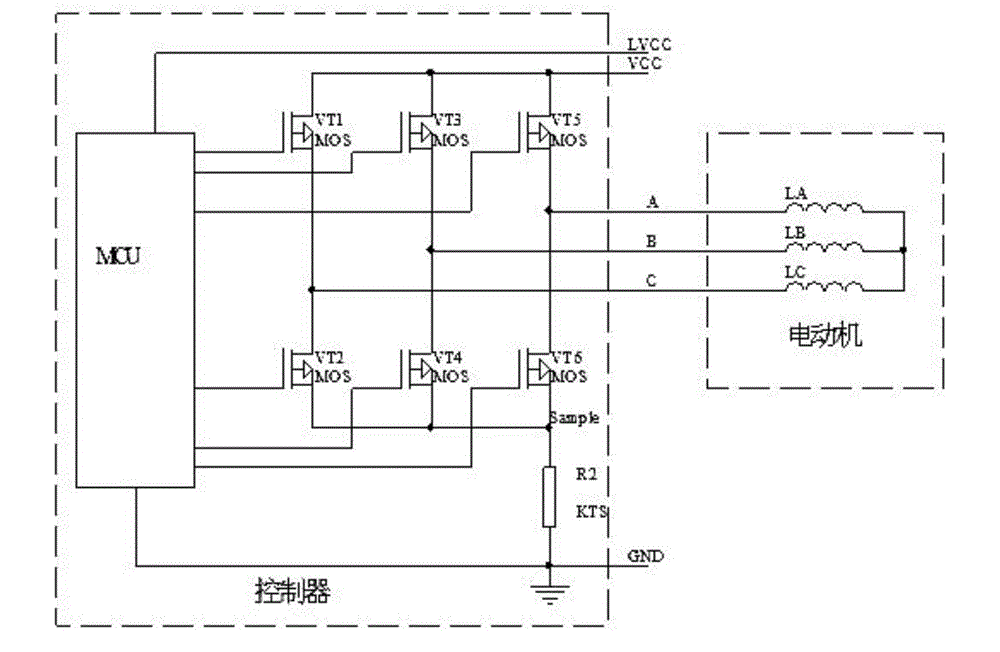

[0020] Step A. Collect self-calibration data, connect the motor controller directly to the constant current power supply, and make the constant current power supply output a constant current equal to the target current limiting current value. The voltage value at the terminal is cyclically sampled, and the average value of the multiple voltage values collected cyclically is calculated by the average value calculation method, and the average value is stored in the storage unit in the motor controller as self-calibration data;

[0021] Step B, when the motor controller is connected to the motor and is in the running state, the single-chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com