Device and method for monitoring aggregate metering process of forced intermittent asphalt stirring equipment

A technology of asphalt mixing and process monitoring, which is applied in measuring devices, program control in sequence/logic controllers, automatic feeding/discharging weighing equipment, etc. It can solve the problem of disjointed quality inspection work, difficulty in real-time monitoring, Problems such as no material and other warehouses or material jam/shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

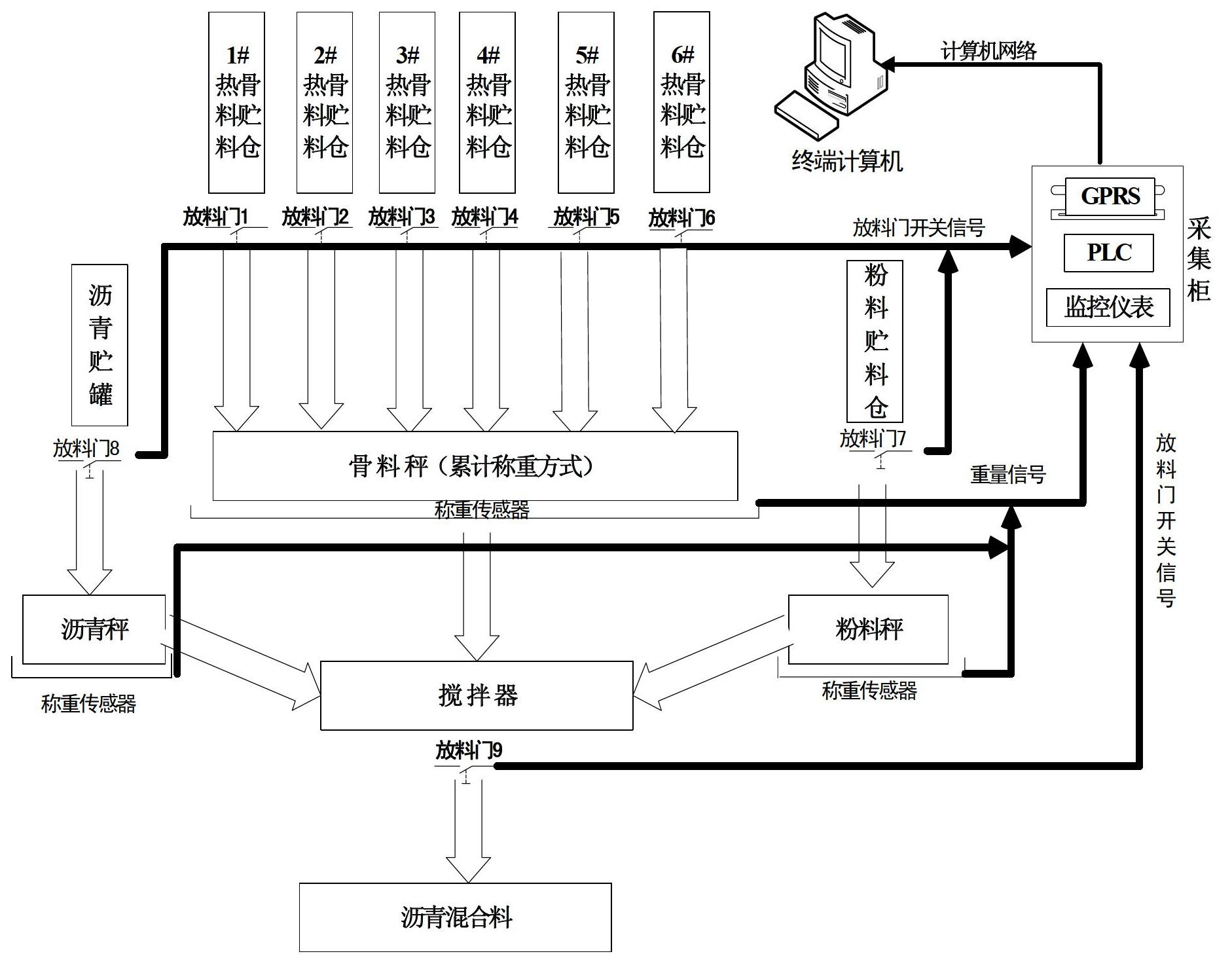

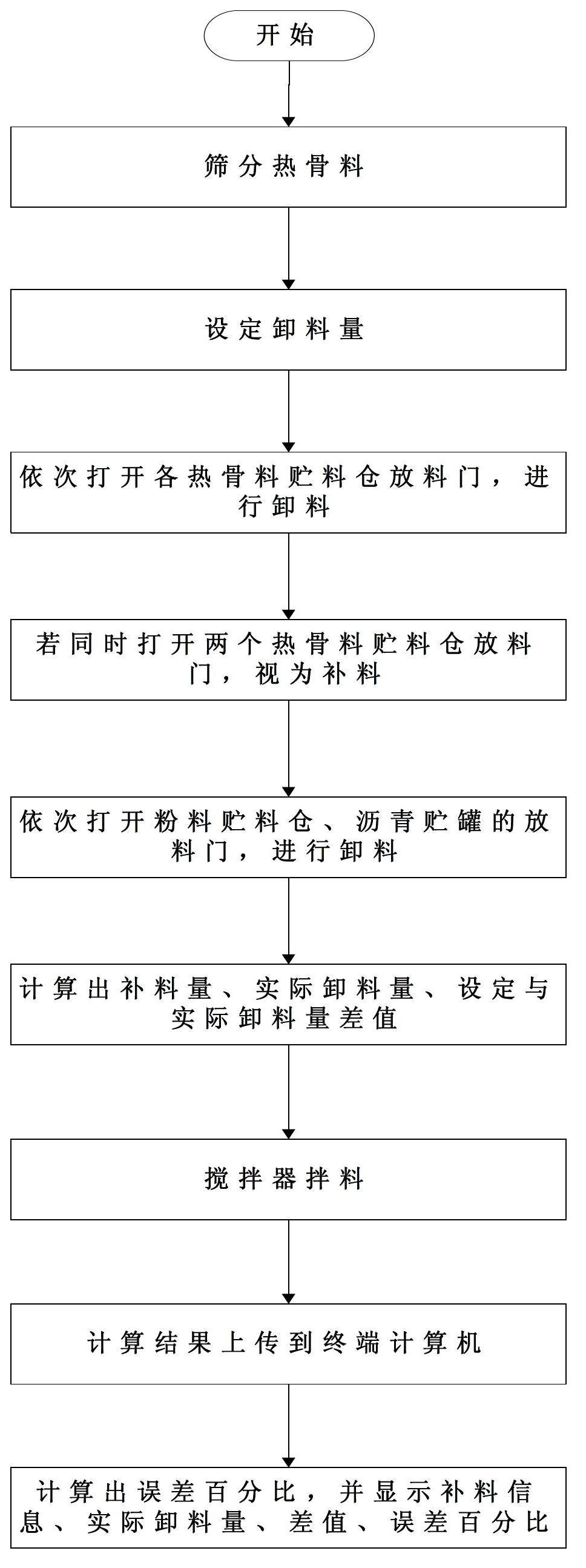

[0058] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

[0059] In this embodiment, the aggregate scale, asphalt scale, powder scale, agitator and weighing sensor are integrated. The model selected is: LB5000 mixing equipment; the model selected for the collection cabinet is: SINYD-CJGⅡ; the model selected for the monitoring instrument It is: SINYD b001; the model selected by PLC is: S7-200 224XPCN; the monitoring system adopts: intelligent collection and monitoring system;

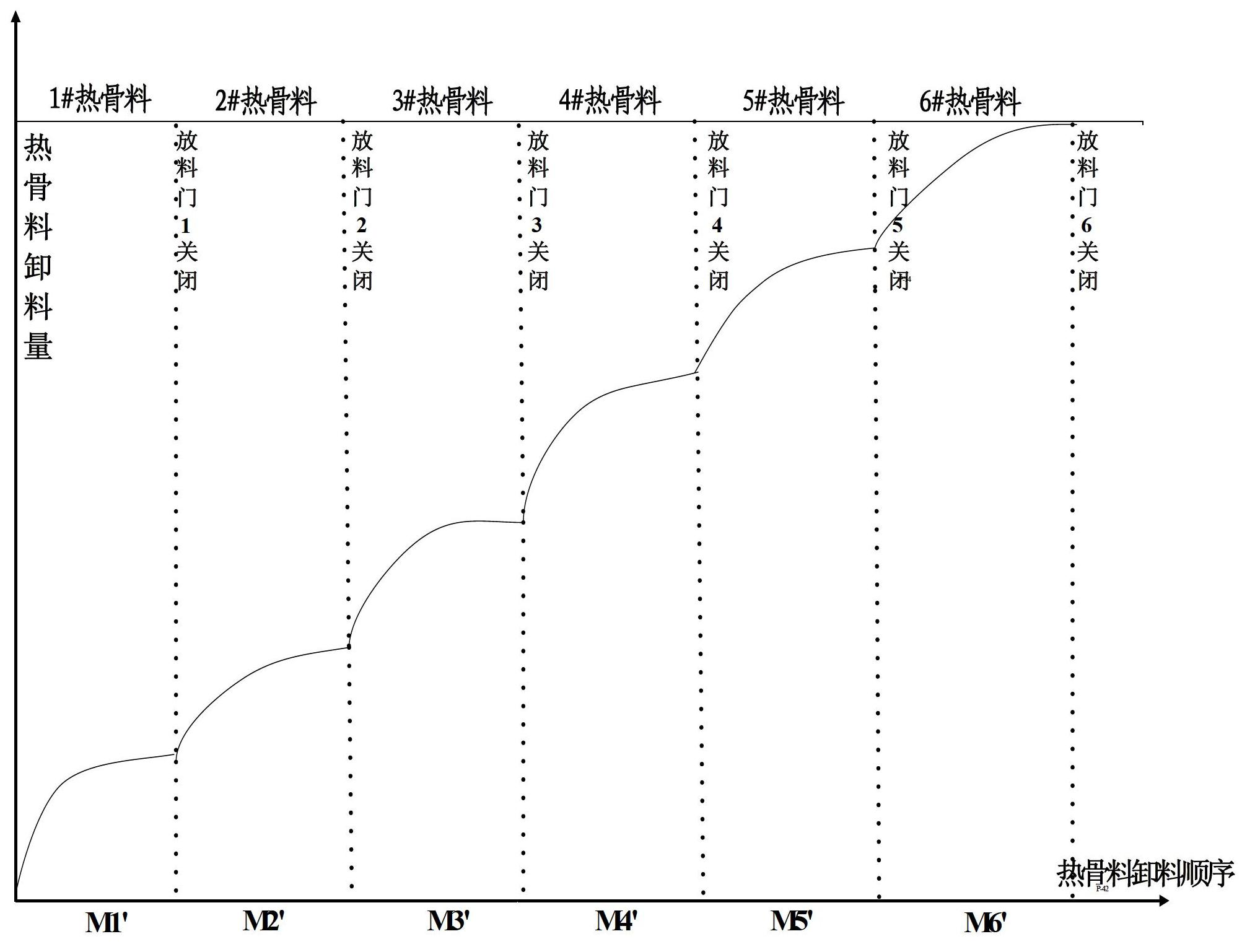

[0060] In this embodiment, the number of thermal aggregate storage bins is 6, which are respectively 1# thermal aggregate storage bin, 2# thermal aggregate storage bin, 3# thermal aggregate storage bin, and 4# thermal aggregate storage bin Storage silo, 5# thermal aggregate storage silo and 6# thermal aggregate storage silo.

[0061] Such as figure 1 As shown, the device includes 6 hot aggregate storage bins, aggregate scales, asphalt scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com