Device and method for automatic optical detection

A technology of automatic optical detection and actual position, which is used in measuring devices, material analysis by optical means, scientific instruments, etc. The effect of storage, improving processing power, and real-time output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

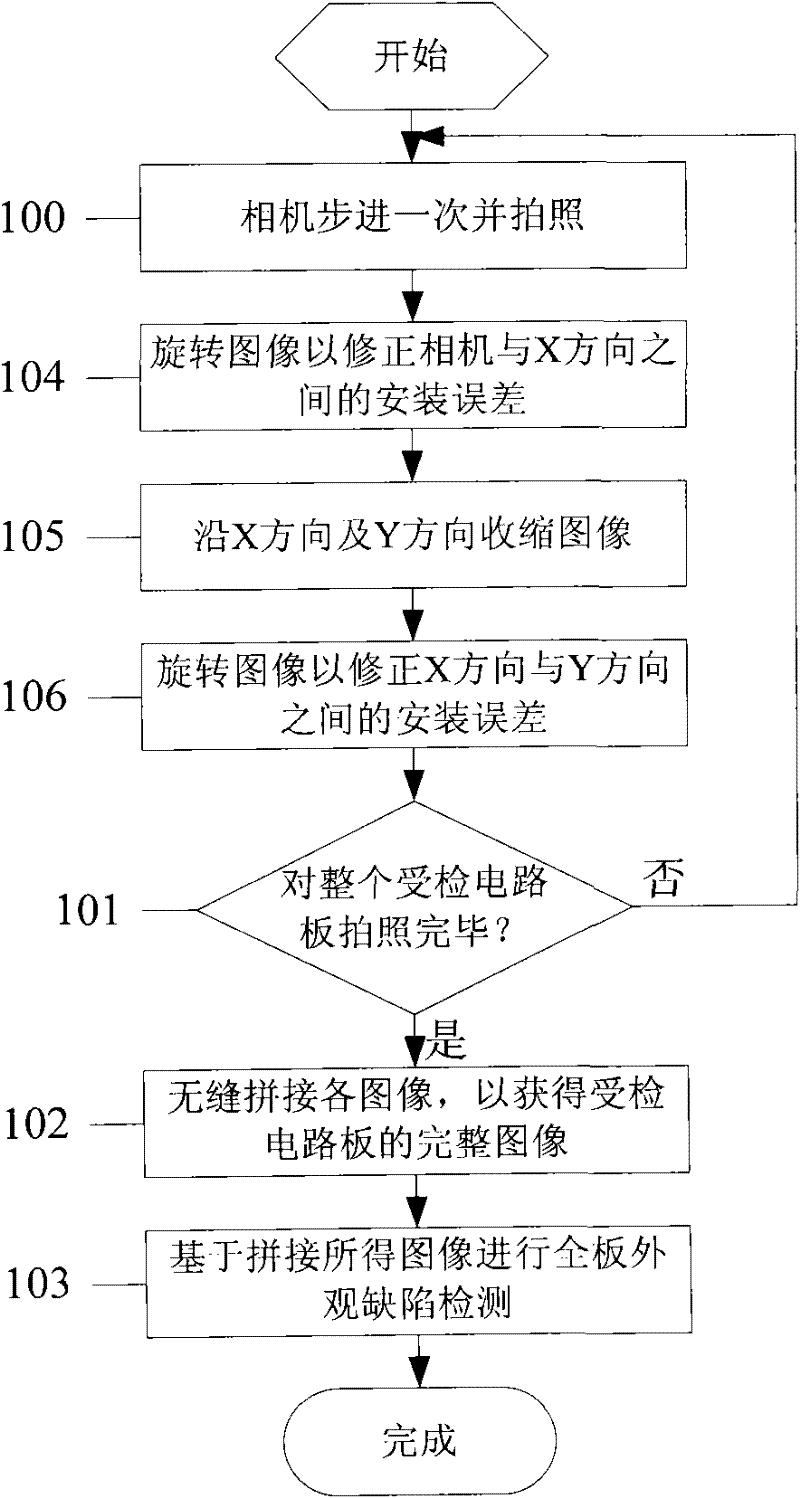

[0031] Hereinafter, preferred embodiments of the present invention are given in conjunction with the drawings to illustrate the technical solutions of the present invention in detail.

[0032] The automatic optical inspection device of the present invention is used for detecting the appearance defects of a circuit board under inspection, such as a PCB. The AOI device includes an image acquisition unit and an image processing unit. The component structure of the image acquisition unit can be the same as the existing image acquisition unit, and the hardware structure of the image processing unit can also be the same as the existing image processing unit. The processing unit is the same.

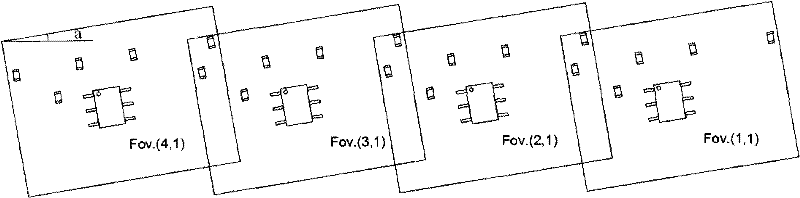

[0033] However, in the present invention, the image acquisition unit is no longer to take selective partial and partial photographs of the inspected circuit board, but to take a comprehensive partial photograph of the entire surface of the inspected circuit board. Specifically, the image acquisitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com