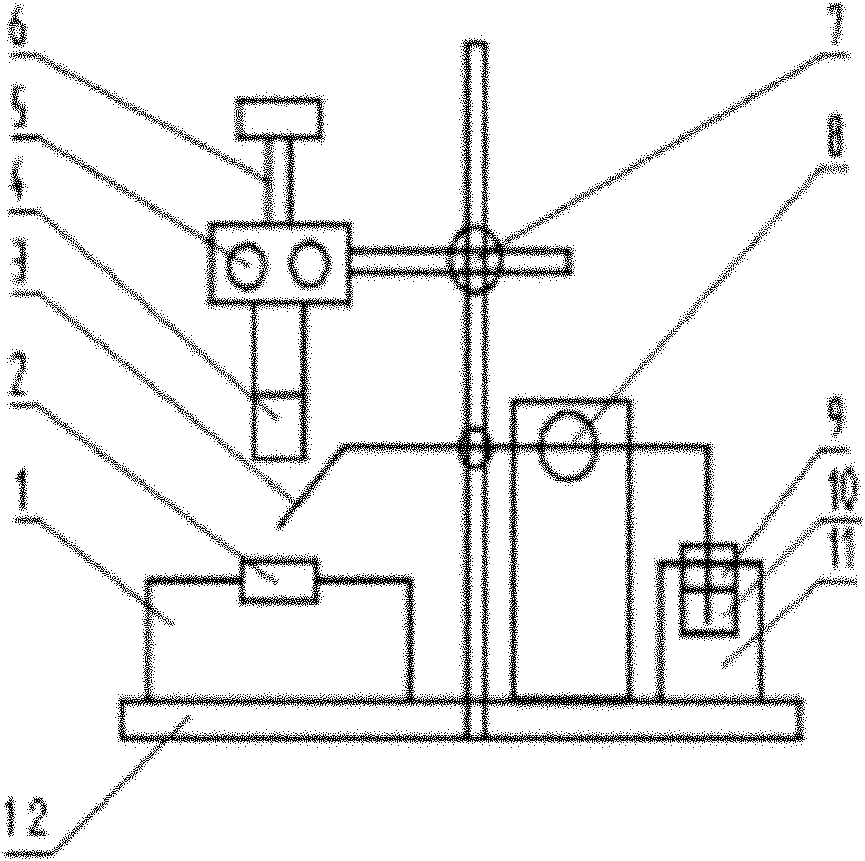

Method and device for testing lubricating oil diffusion rate

A technology of diffusion rate and lubricating oil, which is applied in the field of testing the diffusion rate of lubricating oil, can solve the problems that have not yet been searched for the diffusion performance test and effective evaluation of marine lubricating oil, and achieve the effect of simple method and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

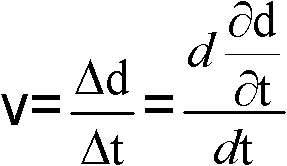

Method used

Image

Examples

Embodiment 1

[0021] Calcium sulfonate detergent test results in diffusion performance evaluation:

[0022] The oil sample used in the test is calcium sulfonate detergent: super high base value calcium benzenesulfonate-T106D: 8%, HVIS 500SN: 92%.

[0023] Experimental conditions: the temperature of the test oil sample is 90±0.5°C; the temperature of the test panel is 200±0.5°C; a drop of the test oil sample is dropped, and the following experimental results are obtained:

[0024] Test time, s

Embodiment 2

[0026] Diffusion performance evaluation of sulfurized alkylphenate calcium detergent:

[0027] Oil sample for test: ultra-high base value sulfurized calcium alkylphenate-T115C: 8%, HVI S 500SN: 92%

[0028] Experimental conditions: the temperature of the oil sample used for the test is 100°C, ±0.5°C; the temperature of the test panel is

[0029] 260°C, ±0.5°C; dripping oil samples for the test, the following experimental results are obtained:

[0030] Test time, s

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com