Dynamic compactor for subgrade

A powerful compaction and roadbed technology, applied in roads, roads, buildings, etc., can solve problems such as poor effect of stabilizing the roadbed, labor-intensive time-consuming, low efficiency, damaged bridge body, etc., to achieve large force, avoid settlement, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

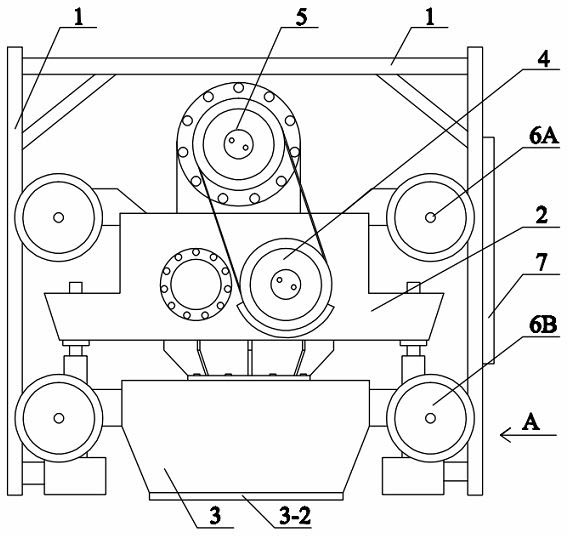

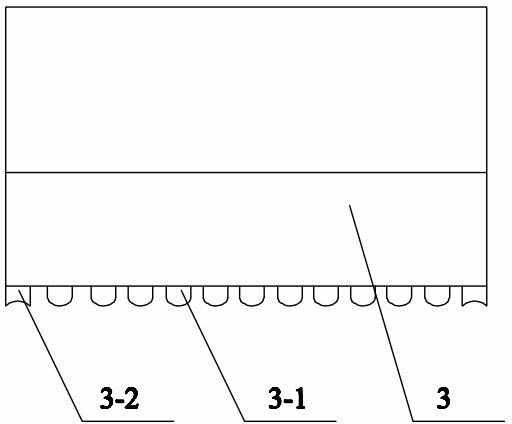

[0010] see figure 1 , a roadbed strong compactor, the structure includes a vibratory hammer mechanism with a vibratory hammer 2, a drive motor 5 and a vibrator 4, the key point is: at the bottom of the vibratory hammer 2, a number of convex strips are evenly distributed on the bottom surface Bottom plate 3, the convex strip structure includes two types: the side pressure breaking plate 3-2 arranged at the edge of the bottom surface of the action bottom plate 3 and the action surface is a concave arc surface, and evenly distributed in the middle of the bottom surface of the action bottom plate 3 And the acting surface is an equalizing convex strip 3-1 with a convex arc surface, and the lateral pressure breaking plate 3-2 cuts off the lateral pressure generated by the vibratory hammer 2 on the soil.

[0011] The above-mentioned protrusions are arranged along the longitudinal or transverse direction of the active bottom plate 3 .

[0012] The structure of the above-mentioned tam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com