Vintage dyeing method for knitted wool fabric

A dyeing method and fabric technology, which is applied in the field of imitation dyeing of knitted wool fabrics, can solve the problems of hard hand feeling, easy sticking to rolls, small batches, and insufficient adaptation to the market demand of multiple varieties, etc. The effect of uniform color and excellent washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dye 20kg 100%60N / 1 preshrunk wool knitted fabric into orange

[0025] (1) Wool fabric pretreatment: Put the fully degreased wool knitted fabric in the dyeing machine, add 400L of water, add 1.0wt% pretreatment agent, heat up to 70°C, keep warm for 20 minutes, discharge the pretreatment solution, and wash with water at 40°C once;

[0026] (2) Cationic modification: enter 400L of water, then add 3.5wt% cationic modifier and 1.0wt% glacial acetic acid, the pH value is 6.9, raise the temperature to 70°C, keep it warm for 20 minutes, drain the residual liquid, and wash once with water at 40°C;

[0027] (3) Dyeing: Inlet 400L of water, add 2.0wt% leveling agent at room temperature, run for 10min, then add 1.6wt% paint, run for 10min, then raise the temperature to 40°C, add 8.0wt% color fixing agent and 3.0wt% Softener, run for 10min, then raise the temperature to 70°C, add 0.3wt% glacial acetic acid, run for 60min, cool down to 60°C, drain, wash twice with water at 40°C.

...

Embodiment 2

[0032] Dye 20kg 100%60N / 1 preshrunk wool knitted fabric into orange

[0033] (1) Wool fabric pretreatment: Put the fully degreased wool knitted fabric in a dyeing machine, add 400L of water, add 3.0wt% pretreatment agent, heat up to 90°C, keep warm for 40 minutes, discharge the pretreatment solution, and wash with water at 40°C once;

[0034] (2) Cationic modification: Inlet 400L of water, then add 3.6wt% cationic modifier and 2.0wt% glacial acetic acid, the pH value is 5.9, raise the temperature to 90°C, keep it warm for 40 minutes, drain the residual liquid, wash once with water at 40°C;

[0035] (3) Dyeing: Inlet 400L of water, add 5g / L sodium sulfate at room temperature, run for 5min, then add 1.8wt% paint, run for 20min, then raise the temperature to 40°C, add 6.0wt% color fixing agent and 4.0wt% Softener, run for 20min, then heat up to 90°C, add 0.3wt% glacial acetic acid, run for 30min, cool down to 60°C, drain, wash twice with water at 40°C.

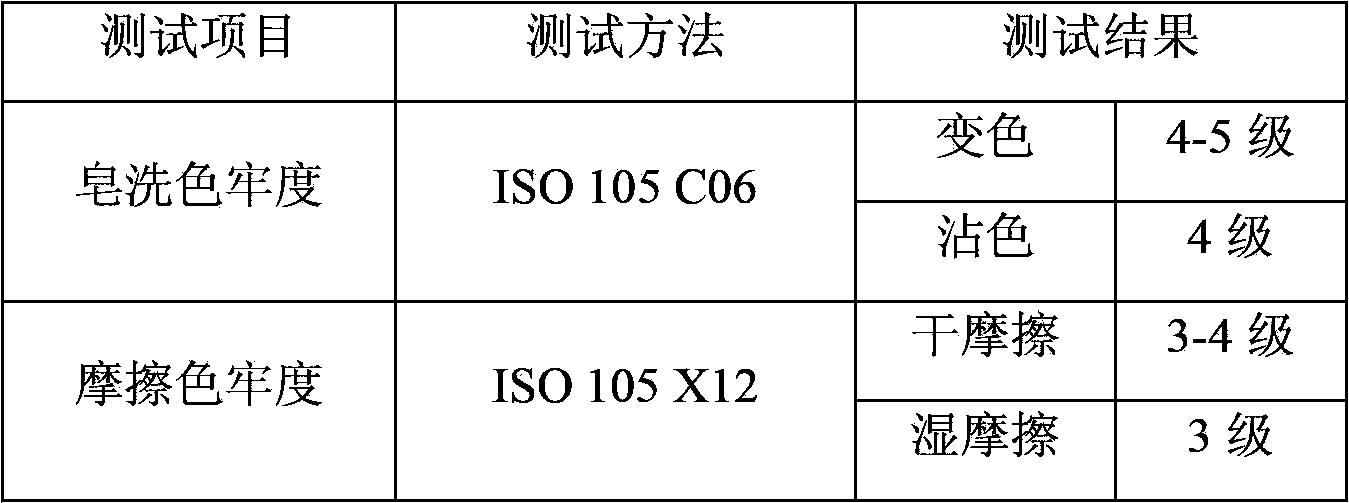

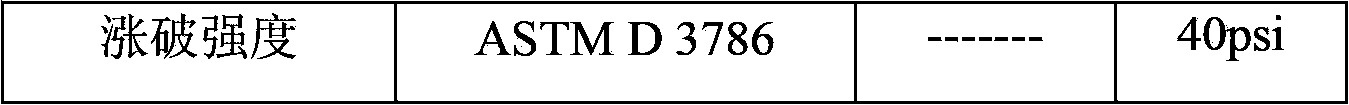

[0036] The fabric test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com