Preparation method of knitted denim fabric

A technology for knitting denim and fabrics, which is applied in knitting, weft knitting, textiles and papermaking, etc., to achieve the effect of comfortable wearing, good hand feeling and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 20S (indigo OE yarn)*20S (bleached combed yarn) knitted denim

[0031] 1. Weaving process

[0032] Machine number: 22G

[0033] Coils (length of 50 pieces): 18.9cm for the 1st and 4th circuits, 13.5cm for the 2nd and 5th circuits, 12.2cm for the 3rd and 6th circuits

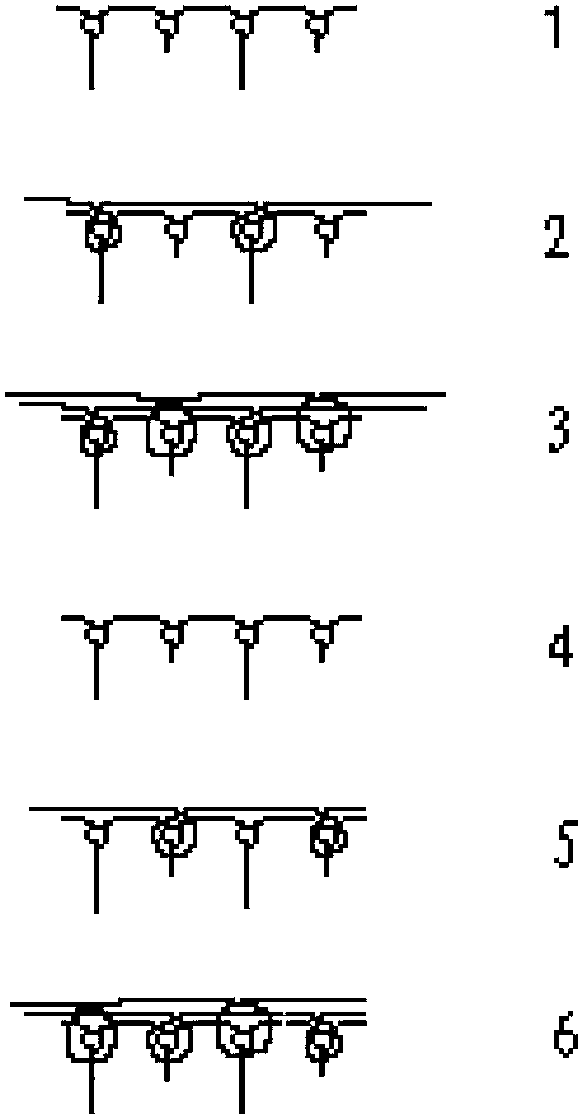

[0034] Arrangement of knitting needles: as figure 1

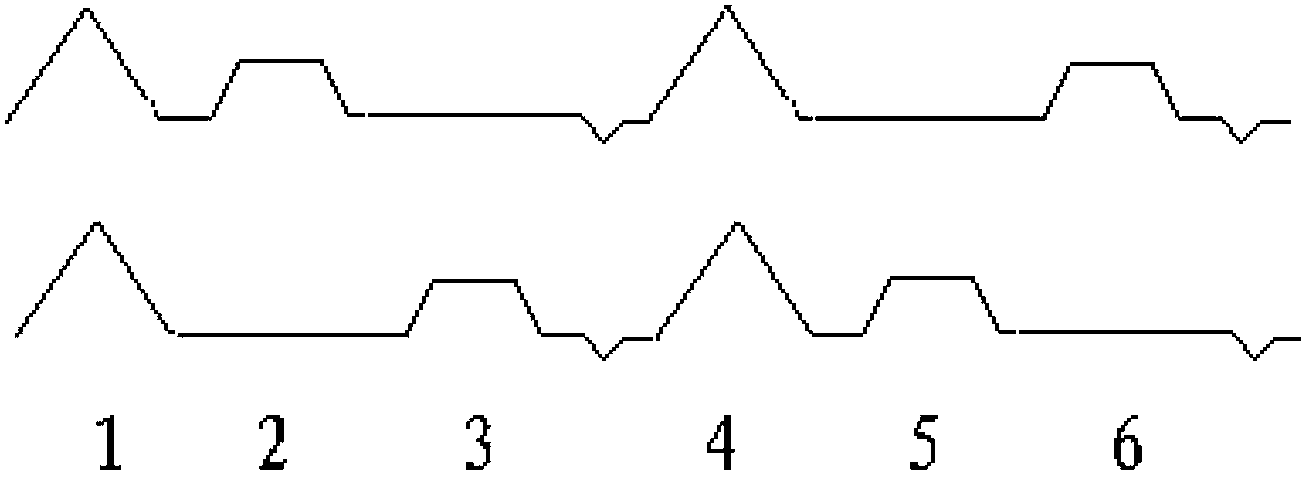

[0035] Triangular arrangement: such as figure 2

[0036] Weaving is completed to obtain rough cloth (such as Figure 7 ) 330g / m 2 about.

[0037] 2. Finishing process

[0038] Neutral cellulase for enzyme washing. Its process parameters are as follows:

[0039] Neutral cellulase: 2% (owf)

[0040] PH value: 7.0

[0041] Antifouling agent: 0.4 (g / L)

[0042] Bath ratio: 1:10

[0043] Temperature: 50°C

[0044] Time: 45min

[0045] After the above process, the light blank gram weight of this example can be obtained as 360g / m 2 Left and right, soft to the touch, high-grade knitted denim fabric with good air permeability (such as Figure...

Embodiment 2

[0047] 20S (indigo OE yarn)*32S (bleached combed yarn) knitted denim

[0048] 1. Weaving process

[0049] Machine number: 22G

[0050] Coils (length of 50 pieces): 19.9cm for the 1st and 4th circuits, 13cm for the 2nd and 5th circuits, 12.5cm for the 3rd and 6th circuits

[0051] Arrangement of knitting needles: as figure 1

[0052] Triangular arrangement: such as figure 2

[0053] Weaving is completed to obtain rough cloth (such as Figure 7 ) 250g / m 2 about.

[0054] 2. Finishing process

[0055] Neutral cellulase for enzyme washing. Its process parameters are as follows:

[0056] Neutral cellulase: 3% (owf)

[0057] PH value: 7.0

[0058] Antifouling agent: 0.5 (g / L)

[0059] Bath ratio: 1:10

[0060] Temperature: 55°C

[0061] Time: 70min

[0062] After the above process, the light blank gram weight of this example can be obtained as 260g / m 2 Left and right, high-grade knitted denim fabric with soft touch and good breathability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com