Edible fungus culture separating method

A technology of edible fungi and strains, applied in the direction of fungi, etc., can solve the problems of easy movement of tissue blocks and increase the chance of pollution, and achieve the effect of reducing pollution links, reducing pollution rates, and facilitating the positioning of germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

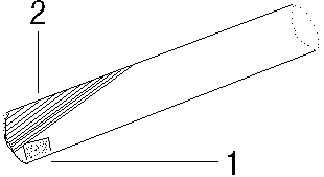

[0012] The method of this embodiment is as follows: after the sharp-nose tweezers and hands are disinfected, use tweezers to clamp the fruit body and rotate it evenly on the flame of an alcohol lamp to remove floating dust and some miscellaneous bacteria on the surface. Then hold the fruiting body vertically to reveal fresh sterile tissue. Burn the front end of the pointed tweezers 2cm in flames and wait for it to cool thoroughly. On the surface of the sterile tissue, use a sharp tip to scratch the size of a corn kernel, and finally, insert it obliquely into the tissue. Break off with tip. The test tube is inclined side down, such as figure 1 Shown in 2. Pull out the tampon with the little finger of the right hand. After the tweezers go off fire, clamp the tissue block, lightly burn it back and forth on the flame 3 times, put it into the test tube, and put the tampon on. Finally, the test tube is tilted, the separation medium faces downward, and the tissue block is shaken ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com