Fruit wine production process of citrus fruit

A production process, the technology of citrus, which is applied in the field of fruit processing and utilization, can solve the problems of low quality and unnatural fruit wine, etc., and achieve the effect of excellent quality, good taste and purity, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] ①Choose ripe pomelo with no pests and diseases and sufficient water content as the raw material, after cleaning, separate the peel and pulp of pomelo, and take the pulp for later use;

[0044] ②After crushing the pulp, add distiller's grains with 5% pulp weight and white sugar with 10% pulp weight, and stir evenly;

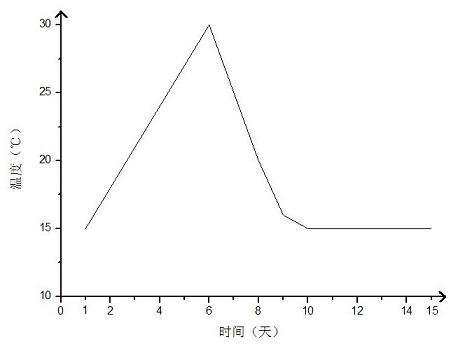

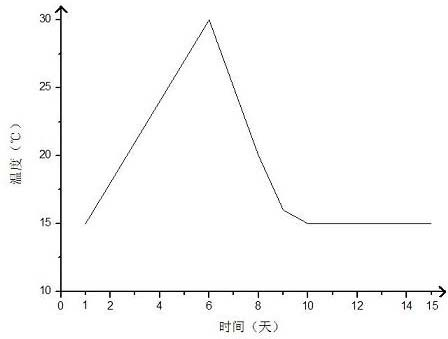

[0045] ③Put the pulp obtained in step ② into a fermenter for fermentation, the temperature of the fermentation is controlled at 15-30°C, and ferment for 7 days;

[0046] ④ After the fermentation is completed, use a siphon to separate the wine liquid from the distiller's grains. After the wine liquid is sterilized at 80°C for 20 minutes, it is filled and sealed to obtain grapefruit wine, and the distiller's grains are reserved for the next production of grapefruit wine and liquor.

[0047] The steps of making liquor from distiller's grains are as follows: press the distiller's grains until the water content is about 35% to obtain dried distiller's grains, ad...

Embodiment 2

[0049] ①Choose mature ponkans without pests and diseases and with sufficient water content as raw materials. After cleaning, separate the peel and pulp of ponkans, and take the pulp for later use;

[0050] ②After crushing the pulp, add distiller's grains with 3% pulp weight and white sugar with 5% pulp weight, and stir evenly;

[0051] ③Put the pulp obtained in step ② into a fermenter for fermentation, the temperature of the fermentation is controlled at 15-30°C, and fermented for 15 days;

[0052] ④ After the fermentation is completed, use a siphon to separate the wine liquid from the distiller's grains, and carry out clarification treatment on the wine liquid. The clarification process is to stand still for 12 hours at a temperature of 15-20°C and in a dark environment, and then sterilize the wine liquid at 85°C for 15 minutes. , the ponkan fruit wine is obtained through filling and sealing, and the distiller's grains are reserved for the next production of the ponkan fruit ...

Embodiment 3

[0055] ①Choose ripe oranges without pests and diseases and with sufficient water content as raw materials. After cleaning, separate the peel and pulp of the oranges, and take the pulp for later use;

[0056] ②After crushing the pulp, add distiller's grains with 4% pulp weight and rock sugar with 8% pulp weight, and stir evenly;

[0057] ③Put the pulp obtained in step ② into a fermenter for fermentation, the temperature of the fermentation is controlled at 15-30°C, and fermented for 10 days;

[0058] ④ After the fermentation is completed, use a siphon to separate the wine liquid from the distiller's grains. After the wine liquid is sterilized at 83°C for 18 minutes, it is filled and sealed to obtain orange fruit wine. The distiller's grains are reserved for the next production of orange fruit wine and white wine.

[0059] The steps of making liquor from distiller's grains are as follows: press the distiller's grains to obtain dried distiller's grains with a water content of abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com