Method for preparing concrete admixture by using biomass

A technology of biomass and admixtures, applied in the direction of cement production, etc., can solve the problems that it is difficult to eliminate the influence of concrete durability, affect the specific surface area of ash, and the low melting point of metals, so as to achieve significant social and economic benefits and ensure safety The effect of reliability and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

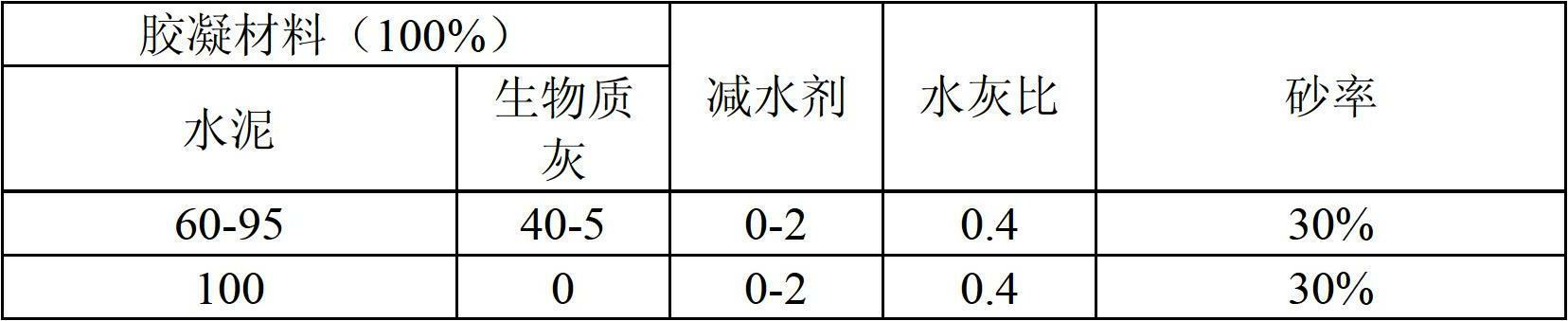

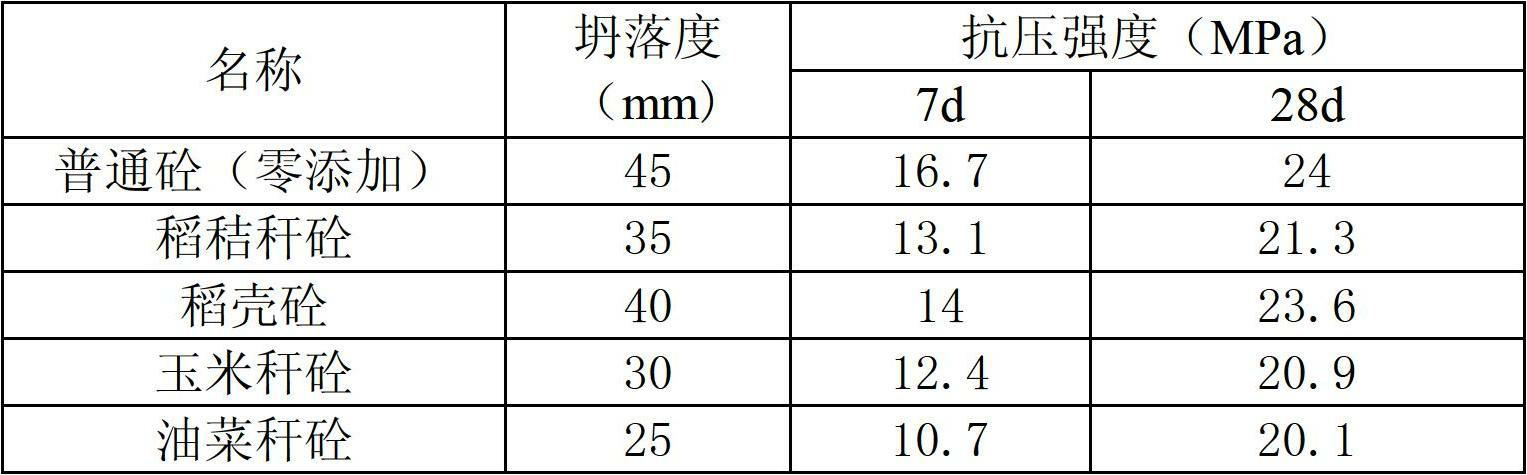

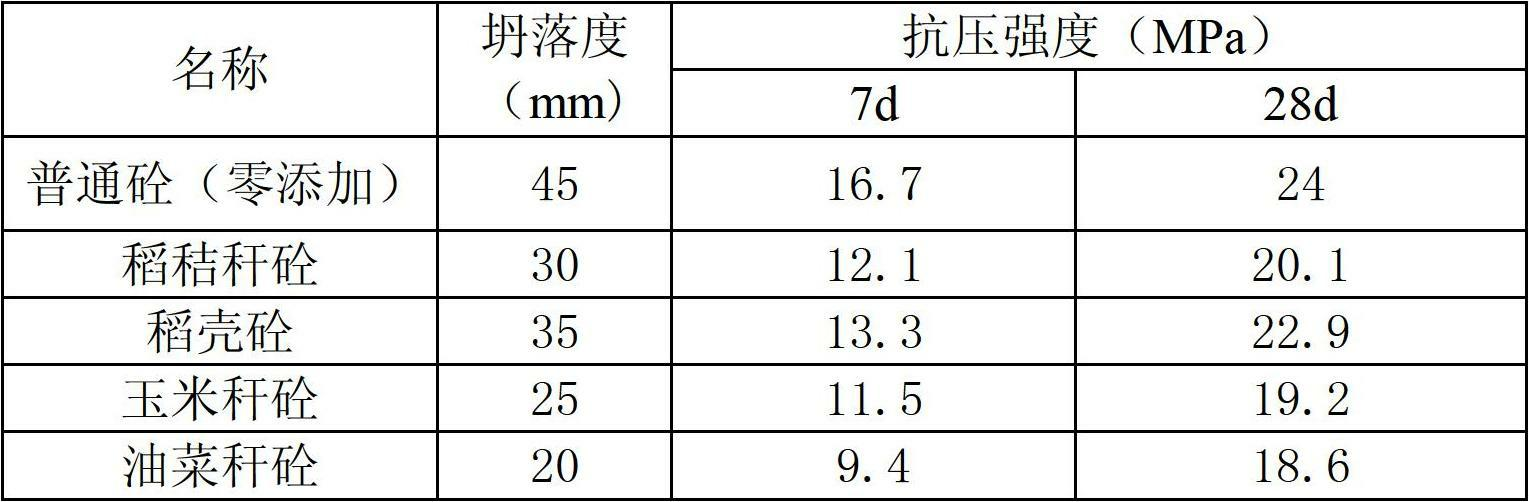

[0019] The biomass used is taken from rice straw, rice husk, corn stalk, and rape stalk from the experimental base of Hunan Agricultural University. After natural drying, it is refined (the length of each biomass is controlled to be ≤20cm), soaked and washed, and then dried. The steps are as follows: Soak the refined biomass in tap water at a temperature of 15°C to 35°C for 24 hours, and control V 水 :m 生 物质 =15ml / g~30ml / g, take it out and dry it. Water temperature, time and liquid-solid ratio (V 水 :m 生物质 ) range is determined on the basis of the following: ①The solubility of substances is related to temperature, the solubility of K contained in biomass increases with the increase of temperature, the solubility of Na contained in biomass is slightly affected by temperature, and the part contained in biomass Ca solubility decreases with increasing temperature. Comprehensively considering the solubility of various water-soluble substances, the difficulty of realizing water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com